CEO Update: A Message from George Yammouni

A strong finish to 2025 with rising PMIs, major service improvements underway, a new customer portal launched, and a positive, growth-focused outlook heading into 2026.

Log in to MyHeadland – your new customer portal | No access yet? Email marketing@headland.com.au

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

In the fast-evolving world of MedTech, precision manufacturing is not just a requirement—it’s the foundation of innovation. As medical devices become smaller, more intricate, and increasingly sophisticated, the demand for precision in their production has skyrocketed. We pride ourselves on providing cutting-edge solutions that empower the MedTech industry to push boundaries and achieve unprecedented accuracy in their operations.

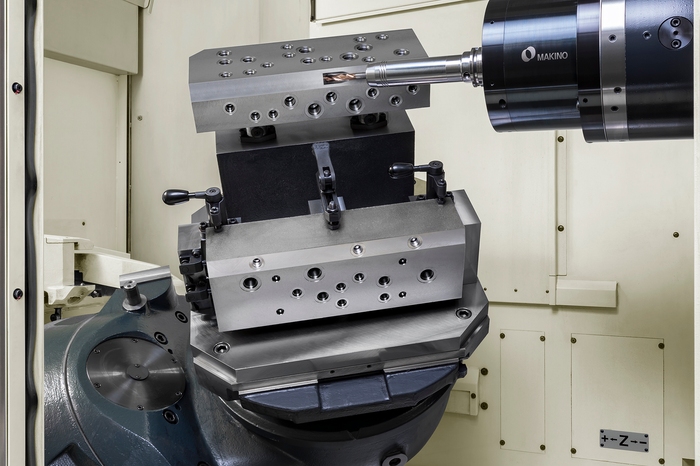

With a robust portfolio that includes top-tier brands like Makino, Nakamura-Tome, and Citizen, we offer the advanced tools and expert guidance needed to produce the most complex medical components. From crafting delicate dental abutments to producing life-saving prosthetics, our precision manufacturing technologies are transforming the way medical devices are designed and delivered.

In this article, we explore the critical role of precision machining in the MedTech landscape and how our arsenal of innovative solutions is enabling manufacturers to set new standards in quality, efficiency, and safety. Whether it’s precision machining centres or automated storage solutions, we are at the forefront of driving Australia’s medical innovation forward.

Makino, a brand offered by us, is synonymous with precision in the medical manufacturing sector. Makino provides a full line of Horizontal & Vertical 3-, 4- and 5-axis machining centres, as well as Wire EDM & Sinker EDM machines. These advanced systems deliver outstanding finishes and stable processing for complex medical components, empowering manufacturers to achieve new levels of accuracy and efficiency. What sets Makino apart is not just its machinery, but its expertise.

By partnering with us for Makino Solutions, medical device manufacturers gain access to:

Nakamura-Tome, another premium brand offered by Headland, is a world leader in multi-tasking mill/turning CNC machines for the medical industry. These CNC machining centres are applied worldwide in the safety-critical medical sector, empowering manufacturers to achieve new levels of efficiency and precision.

Nakamura turning centres are the solution of choice for producing a wide range of medical components, including:

The robust machining platform provided by Nakamura-Tome is essential for delivering superior surface finishes and precision levels. This is crucial in the medical industry, where even the slightest imperfection can have significant consequences.

Nakamura-Tome solutions, medical device manufacturers gain:

The new Citizen sliding-head lathe, specifically designed for medical component production, is a game-changer for crafting small medical implements like dental abutments. This technology empowers manufacturers to produce tiny, intricate parts with consistency and efficiency, meeting the growing demand for miniaturised medical devices.

The Citizen Cincom L12 Type X is a new sliding-head lathe specifically tailored to meet the demands of the medical industry, with a primary focus on the production of dental abutments and implants.

A streamlined storage environment is crucial for many hospitals and healthcare facilities. It’s not just a luxury, it’s an essential part of daily operations. On average, nurses spend 21 minutes per shift searching for lost tools and supplies. This time can be significantly reduced in a hospital or any setting where every minute counts by implementing quality technology like Hänel’s office and storage system products, including the Rotomat®, Lean-Lift®, and Multi-Space®.

Efficient storage and retrieval of medical supplies are crucial in healthcare settings. We sell and service Hänel’s automated storage solutions, including:

These systems have been successfully implemented in hospital central supply depots, significantly improving efficiency and patient care.

We empower Australian medical technology companies to scale and innovate through our comprehensive technology solutions. Our offerings enable:

By providing advanced technologies we’re helping to shape the future of healthcare both locally and globally.

We partner with MedTech firms to:

As Australia’s MedTech sector expands, we remain committed to providing the technological foundation for its continued success.

Whether you’re developing intricate surgical instruments, producing diagnostic equipment, or manufacturing implantable devices, our technology experts can provide tailored solutions to meet your specific needs. Contact our team of experts to explore how these technologies can drive innovation and efficiency in your MedTech manufacturing processes.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

Automated Warehouse Storage for sale in Australia and New Zealand. Hanel and STOPA storage systems.

CNC Lathes for sale in Australia and New Zealand. Nakamura-Tome, Hyundai WIA, Citizen, Geminis, WFL, Bost.

High accuracy horizontal machining centers for sale in Australia and New Zealand. Hyundai WIA, Makino, Shibaura.

High precision vertical machining centers for sale in Australia and New Zealand. Hyundai WIA, Makino, Shibaura.

The next-generation L32, which has a history as one of the best-selling Cincom machines, debuts with 4 models in a modular design.