Introducing MyHeadland: Your new customer portal

MyHeadland is here; your 24/7, all-in-one view of everything that matters to you, in one secure place.

Log in to MyHeadland – your new customer portal | No access yet? Email marketing@headland.com.au

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

Cutting coolant is all-too-often overlooked as a major component of a machining operation. The type of coolant or lubricant and the pressure at which it is applied is vital. It is vital to both machining success and shop efficiency. You can apply coolant as compressed air, mist, in a flooding property, or as high pressure.

We recommend using cutting coolants for chip clearing, lubrication, and cooling of CNC machinery.

Check the condition of your cutting coolant. This will ensure your machining process is as efficient as possible.

If necessary, do a complete drain, then replenish it.

You should usually complete this on an annual basis.

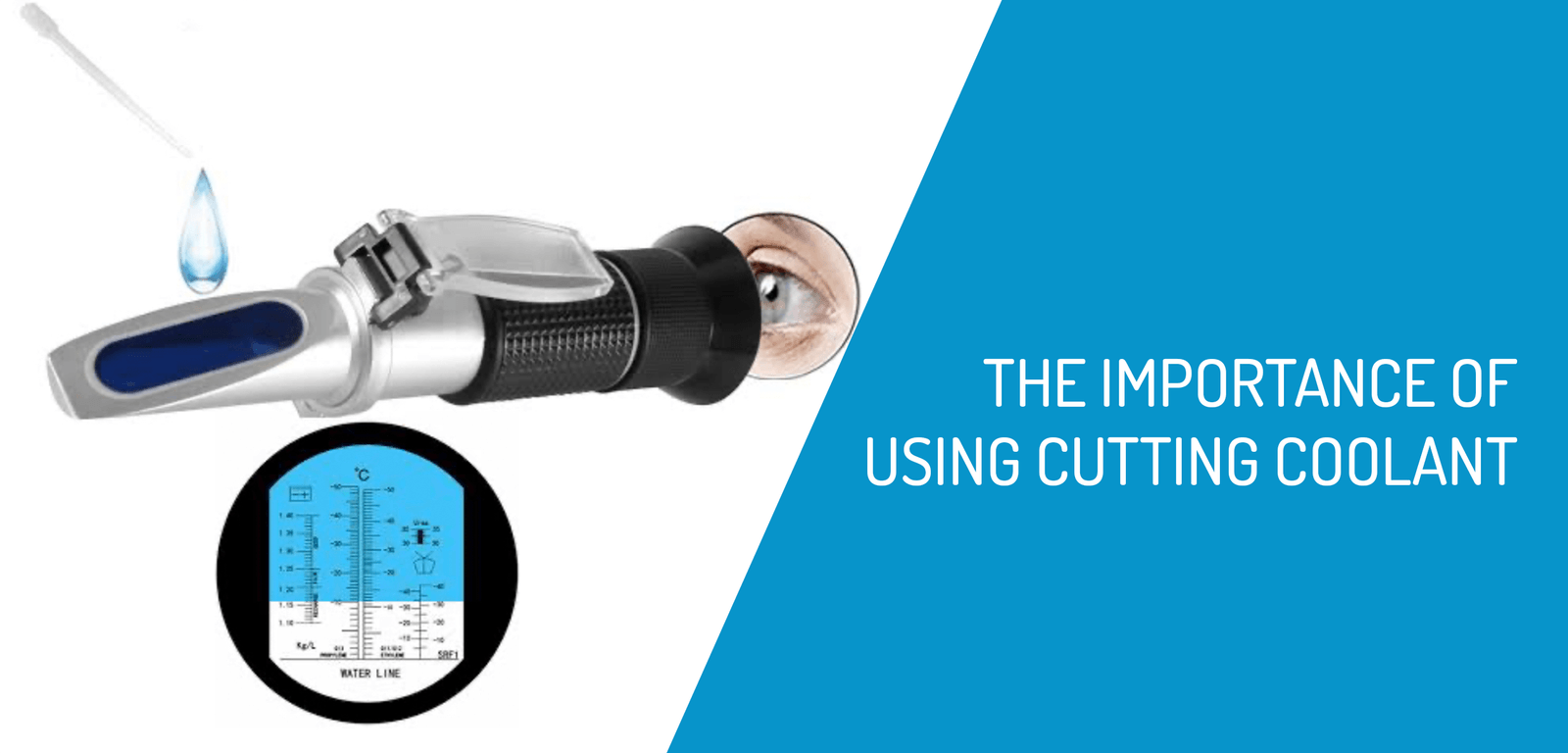

Using a refractometer, check the concentration of your specific brand of cutting coolant.

Are you experiencing issues taking care of your machines?

If you require any assistance with servicing or would like to learn more about maintenance, contact us.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.