In the competitive world of manufacturing, cost pressures often push businesses to consider cheaper machinery options. However, cutting corners on equipment certification can lead to serious safety risks, compliance headaches, and unexpected costs.

More and more Australian manufacturers are importing non-certified machinery only to face safety failures, costly retrofits, or complete replacements.

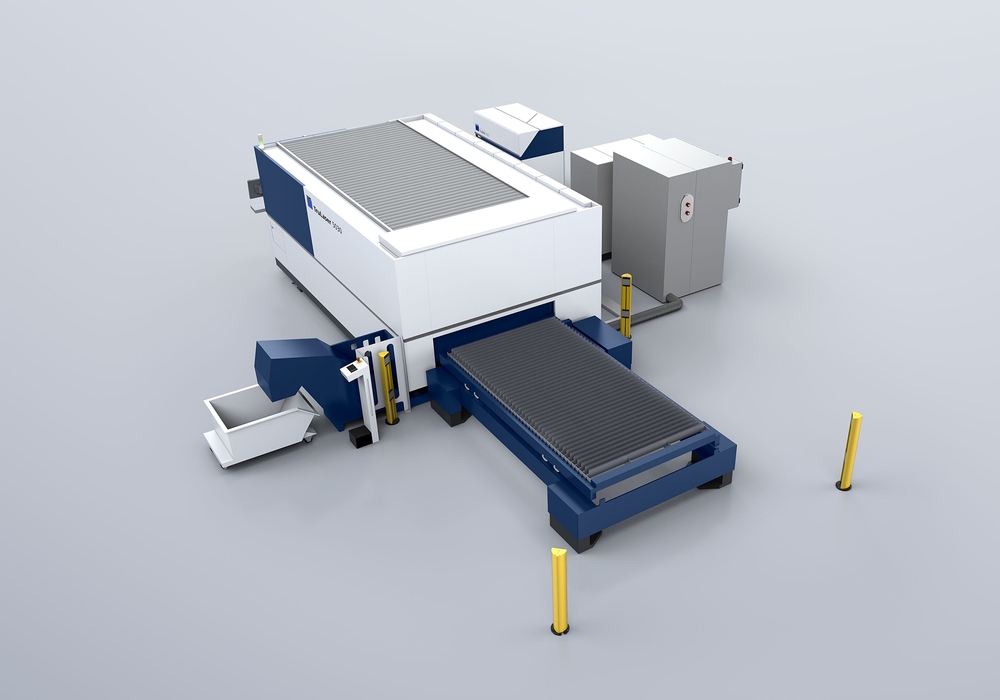

While not legally required in Australia, at Headland Technology, we only sell and service either CE-certified or AS/NZS-4024 compliant machinery, ensuring our clients receive the highest safety and performance standards. Here’s why certified machinery should be non-negotiable for your business.

What is CE Certification and its relevance in Australia

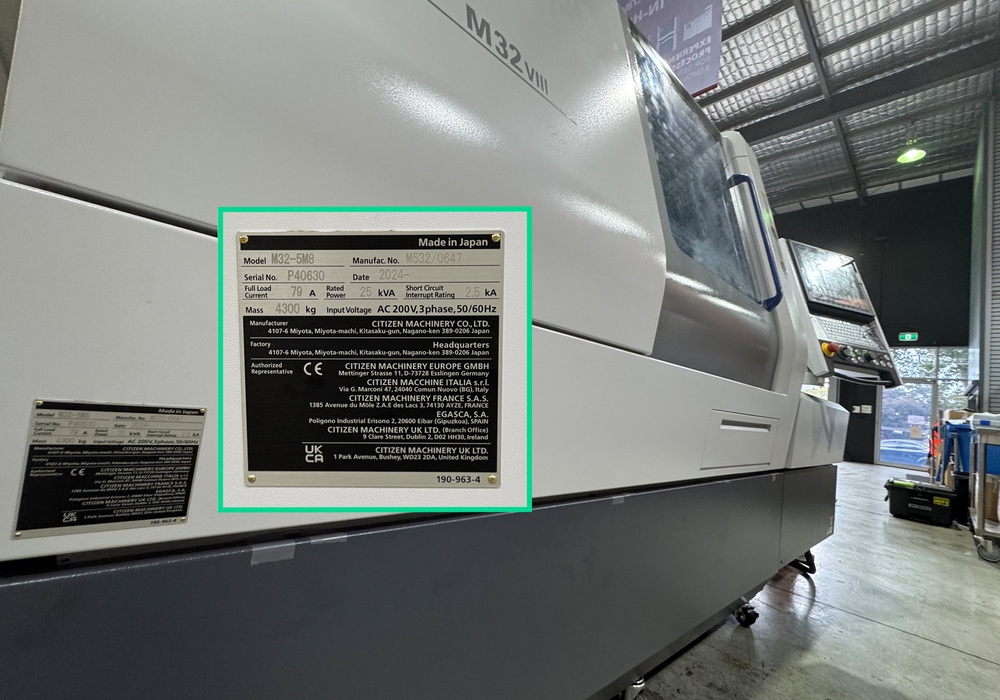

CE certification, or CE marking, is the European Union’s gold standard for machinery safety, reliability, and environmental compliance.

The CE mark indicates that the manufacturer has assessed the machinery and verified its compliance with relevant EU directives. CE marking includes a logo and, when applicable, a four-digit identification number of the Notified Body involved in the conformity assessment. Machines with this certification have undergone rigorous testing to ensure they meet European Union regulations and essential safety requirements.

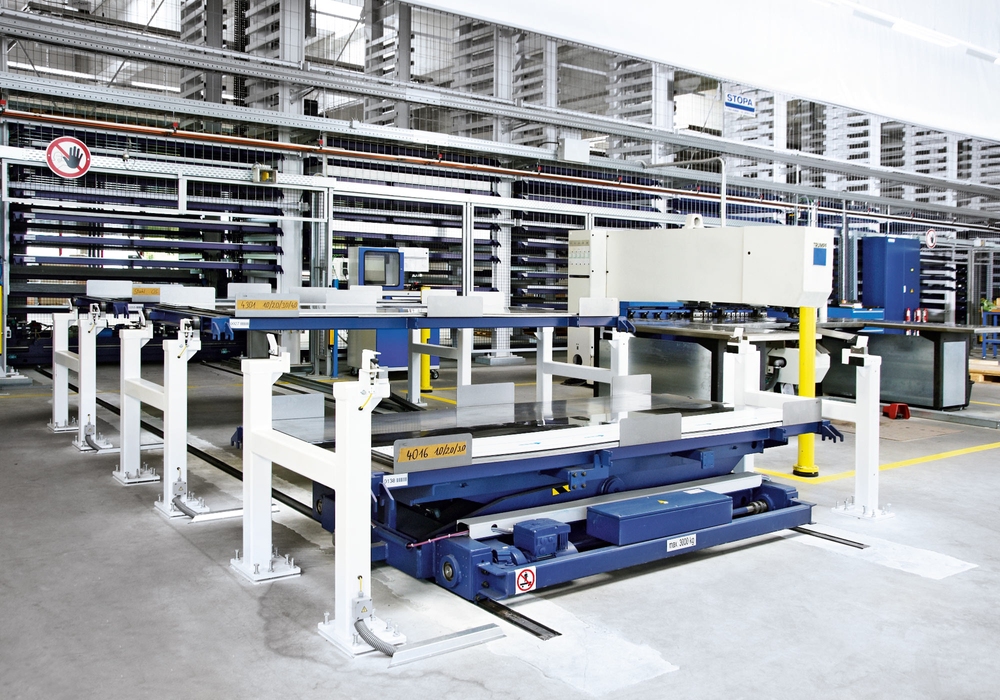

- Higher safety standards: Reduced risk of workplace accidents and equipment failures.

- Operational reliability: Machines are designed and tested to function safely under normal and foreseeable conditions.

- Future-proofing your investment: Ensuring compliance with international safety and environmental standards, avoiding potential future restrictions.

CE certification is an EU requirement that is globally recognised as the highest standard of machinery quality and compliance. While Australia does not mandate CE certification, manufacturers who overlook it may face unforeseen challenges when acquiring non-certified machinery.

The True Cost of Non-Certified Machinery

Many manufacturers opt for non-certified machinery due to lower upfront costs—but these machines come with hidden risks:

- Regulatory compliance issues – If the machine doesn’t meet safety or environmental standards, you may need to retrofit, modify, or replace it—at great expense.

- Operational downtime & safety hazards – Non-certified machines can lack essential safety features, increasing the risk of breakdowns, workplace injuries, or even total shutdowns.

- Resale & export limitations – Selling or exporting non-certified machines to regulated markets (like the EU) is often impossible, limiting future business opportunities.

- Insurance & liability risks – Many insurers refuse to cover non-certified equipment. If an accident occurs, your business could face significant legal and financial penalties.

- Lack of spare parts & support – Many non-certified machines are unsupported by manufacturers, leading to long lead times for repairs and higher maintenance costs.

- Inconsistent performance & quality issues – Non-certified machines often lack standardised production quality, leading to product defects, wasted materials, and lower productivity.

Why choose Headland Technology?

At Headland Technology, we only sell and service CE-certified or AS/NZS-4024 compliant machinery, ensuring that your equipment meets the highest global standards for safety, reliability, and efficiency.

Partnering with us means:

- No costly compliance surprises – Our machines meet the strictest safety and environmental regulations.

- Minimal downtime, maximum productivity – Certified machines ensure consistent, high-quality performance.

- Expert service & support – Our team provides ongoing maintenance, training, and technical assistance.

- Readily available spare parts – Avoid long wait times for replacements and keep operations running smoothly.

- Stronger resale value – Certified machinery retains higher value and appeals to global buyers.

- Enhance your company’s reputation by using internationally recognised, high-quality machinery that meets global safety and performance standards.

Unlock your success with the right machine: Partner with us for a reliable CE-certified solution.

Investing in the right equipment is crucial for your business’s growth and safety. With Headland Technology, you gain a trusted partner dedicated to delivering machines that meet the highest international standards. Say goodbye to risks and inefficiencies—choose from our extensive portfolio of CE-certified solutions tailored to your manufacturing needs. Let’s build a safer, smarter future together!