Come visit us on stand MT118 at Australian Manufacturing Week 2024 (April 17-19). This year AMW will be held at the ICC Sydney in Darling Harbour.

The focus of our stand this year will be metal fabrication technology. Our expert metal fab team (Tim Stoddard, Joe Tippel, Matthew Weaver) will be on hand and available to demo our machines and discuss any other applications you may have in mind. They look forward to seeing you there!

Live machine demos:

OMAX MAXIEM 1530 Waterjet Cutting Machine

Especially suited for high-precision cutting

The highly advanced software in the MAXIEM provides one-micron resolution instant feedback to the motor system, allowing the machine to know where the cutting head is at all times to minute detail, making this machine highly suited to high precision parts.

Easier to use than ever before

Easy operation was first in mind for the MAXIEM – it’s mobile control station with 23″ widescreen display allows a high level of flexibility in controller positioning and makes it easier than ever to keep an overview of your programming jobs. 5-axis cutting is possible with the optional A-Jet accessory, as well as taper compensation and rapid water level control for submerged cutting.

Due to limited tool change and minimal fixturing, the MAXIEM setup times are dramatically reduced allowing you to program and run jobs faster than ever before.

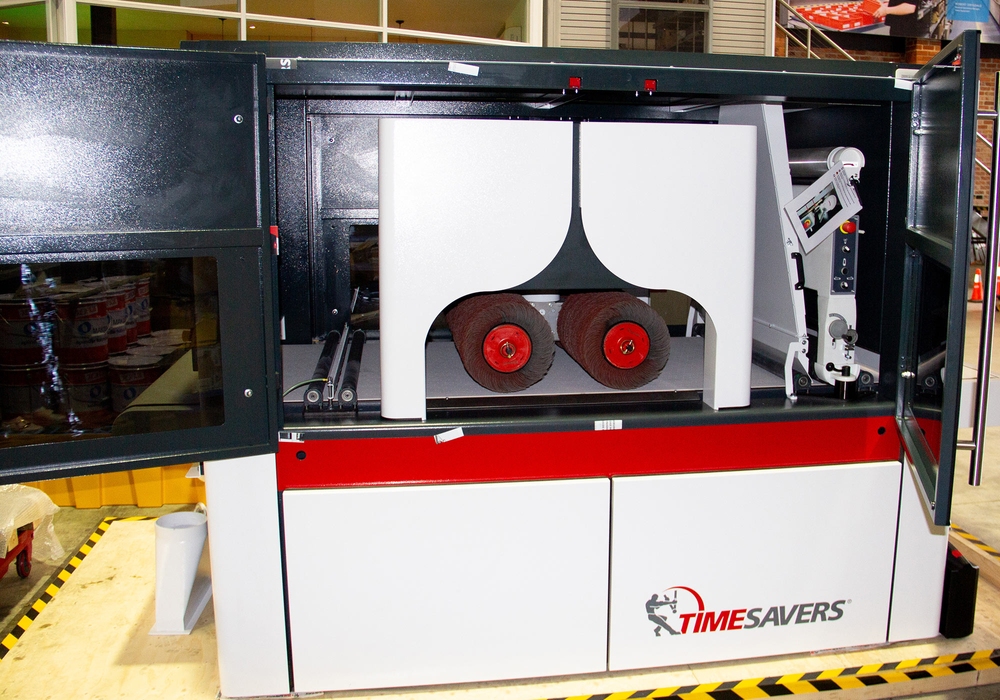

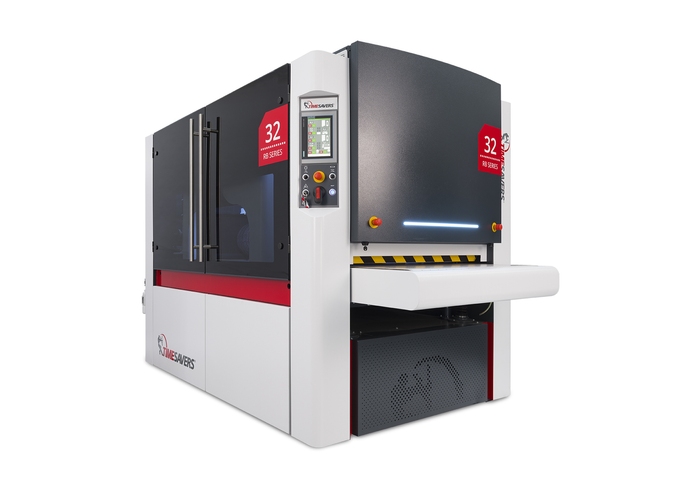

Timesavers 32 Series Deburring & Linishing Machine

The Timesavers 32 is the ideal choice for quickly removing stubborn slag, dross, and hardened spatter left behind from plasma cutting operations. The hammerhead’s rapidly oscillating pins hammer away built-up material at up to 22 m/sec, deburring and linishing edges up to 2mm in a single pass. With an 1100mm working width, the 32 can process large parts while also securely holding smaller 50x50mm components in place with optional magnetic tracks.