CEO Update: A Message from George Yammouni

A strong finish to 2025 with rising PMIs, major service improvements underway, a new customer portal launched, and a positive, growth-focused outlook heading into 2026.

Log in to MyHeadland – your new customer portal | No access yet? Email marketing@headland.com.au

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

Revolutionary advances promise significant energy savings, enhanced productivity, and superior cutting performance over traditional CO₂ systems.

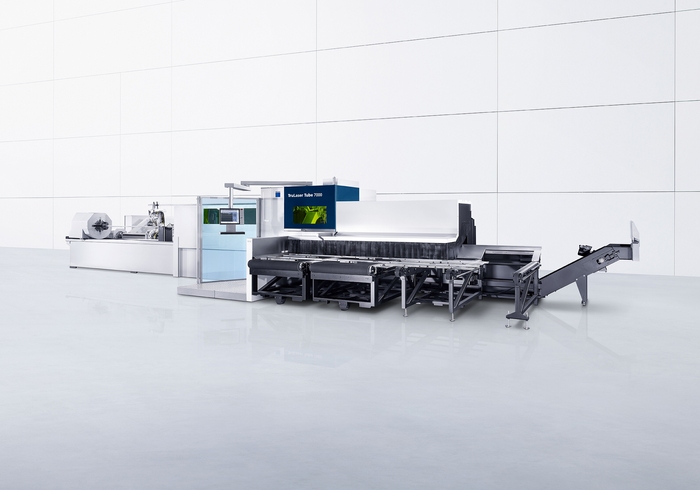

TRUMPF’s latest presentation heralds a transformative leap in tube cutting technology, as its new fiber laser solutions set a new benchmark against conventional CO₂ systems. The company’s cutting-edge TruLaser Tube Fiber machines, showcased alongside their CO₂ counterparts, offer dramatic improvements in efficiency and performance—a development that could reshape manufacturing processes across the metalworking industry.

This article presents detailed insights from side-by-side comparisons between TRUMPF’s CO₂ andfiber laser systems across different machine series. In the TruLaser Tube 5000 series, for example, the TruLaser Tube 4000 fiber cutting system demonstrates:

For the 7000 series, the performance gap widens further. The TruLaser Tube 6000 fiber laser:

A standout metric from the data is the reported increase in cutting speed—up to +366%—when switching from CO₂ to fiber laser technology in large contour cutting operations.

Beyond raw performance, TRUMPF’s new systems feature innovative programming solutions. The “Programming Tube” software suite integrates seamlessly with industry-leading CAD systems like SolidWorks, enabling:

TRUMPF’s expanded portfolio now spans three key series—TruLaser Tube 3000, 5000, and 7000 fiber laser cutting machines—each tailored to different production needs:

Additional cutting-edge options like RapidCut, SpatterGuard, and specialised tapping/beveling packages further enhance versatility and efficiency.

TRUMPF’s strategic shift to fiber laser technology not only underlines a commitment to sustainable manufacturing but also positions the company at the forefront of industrial innovation. The substantial reductions in energy consumption, elimination of costly laser gases, and marked improvements in cutting speeds and precision are poised to deliver significant operational savings for manufacturers. As these systems become more widely adopted, the broader industry can expect enhanced productivity and a reduced environmental footprint.

For more detailed information, interested parties are encouraged to visit TRUMPF’s website at www.trumpf.com.

Contact our TRUMPF experts and sheet metal experts now to:

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

TRUMPF TruLaser Tube 3000 Fiber, for supplementary machine use or first time users. Efficient and easy to operate.

The TruLaser Tube 5000 fiber saves up to 40% of your time. Needs-based lens cleaning, and the lens failure sensor system.

The TruLaser Tube 7000 Fiber: Technology Designers Love. Cover a wide range of parts and open up new areas of application.