Australia’s manufacturing industry is at a crossroads. A national shortage of skilled welders, coupled with the rising demand for high-quality welds in industries like aerospace, automotive, and construction, has placed immense pressure on fabricators. The TRUMPF TruLaser Weld 5000 offers a transformative solution—enabling manufacturers to bridge the skills gap, deliver unmatched quality, and expand into lucrative new markets.

Meeting market demands with high-quality Welds

Customers increasingly demand precision and high-quality finishes in their products. The TruLaser Weld 5000 is the next generation of laser welding, delivering on these requirements with brand new high technology features such as:

- Brightline Scan: High frequency welding contours enable precise welding seams and stronger connections

- FusionLine Technology: Allows for welding of components with gaps, broadening the range of parts manufacturers can handle. Did you know: FusionLine is a new laser welding process that can be used for components with gaps. Switching over to deep penetration welding or heat conduction welding is possible directly in the process without manual intervention. Combine the different processes on one component to benefit from the respective advantages.

- Precision Welding: Seamlessly handles deep, robust welds or fine, smooth finishes depending on project needs.

- Consistent Results: Robotic automation ensures every weld meets the same exacting standards, eliminating the variability of manual processes.

Advanced technology integration

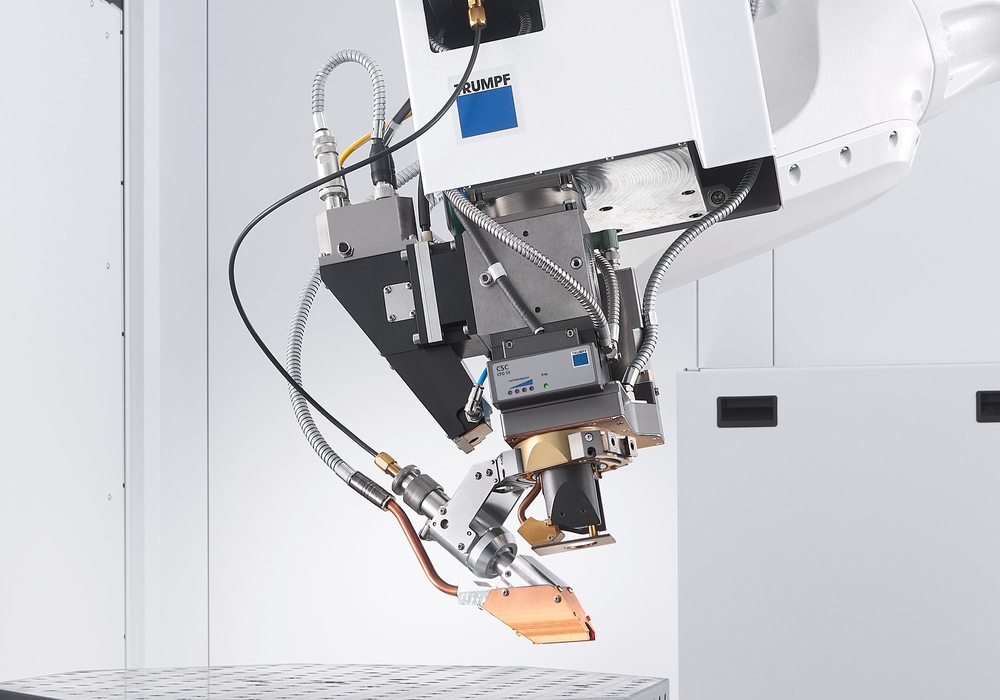

The TruLaser Weld 5000’s excellence stems from its perfectly integrated core components:

High-performance industrial robotics: At the heart of the system lies a robust, industry-proven robot known for its precision and reliability. These low-maintenance robots have been validated through thousands of industrial applications, ensuring consistent performance and longevity.

Cutting-edge laser and optics: TRUMPF’s integrated approach features comprehensive laser and optics systems, with the standout BrightLine Scan optics combining scanner and focusing capabilities. This innovative solution includes customised beam guidance tailored to specific welding requirements. Did you know: BrightLine Scan stands for a new laser welding optics with the possibility to move the laser beam through two programmable mirrors on the workpiece surface. This allows the laser beam to be moved simultaneously via the robot and the optics, which also makes it possible to reproduce different welding sequences. The oscillation frequencies are generated in a field with a diameter of 9 mm.

Intelligent features for enhanced productivity: The system incorporates the TeachLine sensor technology, which automatically detects seam placement, ensuring precise welding even with part-to-part variations. A user-friendly interface featuring a rotatable control panel and additional status monitor makes operation intuitive and efficient.

Key advantages for sheet metal fabricators

Enhanced production speed: Laser welding operates up to four times faster than traditional TIG welding, enabling businesses to increase throughput without compromising quality.

Streamlined operations: The TruLaser Weld 5000 integrates all essential components—robot, laser, optics, and safety enclosure—into a single, plug-and-play system, maximising efficiency on the production floor.

Cost and waste reduction: The precision of laser welding significantly reduces material waste and rework, leading to lower operational costs and improved sustainability.

Future proofing your workforce: By automating welding processes, manufacturers can reduce their dependence on skilled welders while enabling existing employees to focus on higher-value tasks, effectively future-proofing their operations.

Strategic investment for long-term growth

The TruLaser Weld 5000 represents more than just a welding solution—it’s an investment in manufacturing excellence. With integrated parameter databases, comprehensive training support, and continuous innovation, this system enables manufacturers to:

- Bridge the skilled labour shortage

- Deliver consistent, high-quality results

- Expand into lucrative new markets

- Maintain competitiveness in an evolving industry

Conclusion

TRUMPF’s TruLaser Weld 5000 is revolutionising the sheet metal fabrication industry by addressing critical challenges while opening new opportunities. Through its combination of advanced robotics, precise optics, and intelligent automation, this system enables manufacturers to achieve unprecedented levels of quality, efficiency, and productivity. As the manufacturing landscape continues to evolve, the TruLaser Weld 5000 stands as a strategic investment in long-term success and growth.

Ready to take your welding capabilities to the next level?

Transform your production with the TruLaser Weld 5000 and unlock 4x faster welding speeds, flawless precision, and automated excellence – all while maximising your workforce potential. Contact our TRUMPF experts to elevate your manufacturing success.