Automation and robotics have transformed the way manufacturers operate, delivering higher productivity, safer workplaces with improved product quality. Surface cleaning is an often overlooked and challenging step in the automation journey. Traditional methods like media blasting and chemical cleaning can be difficult to automate, costly, and inconsistent. Trusted by machine builders and integrators alike, TRUMPF laser cleaning equipment sets a new standard for automated surface preparation in the manufacturing sector.

The critical role of surface preparation

Surface preparation is the foundation of successful manufacturing processes. Clean, contaminant-free surfaces ensure proper adhesion for coatings, strong welds, and enhanced corrosion resistance. On the other hand, poor preparation can lead to failures, costly rework, production delays, and safety issues. In industries where quality and reliability are paramount, surface preparation is non-negotiable. As manufacturers adopt automation to streamline workflows, the surface cleaning step must also evolve to meet new standards of consistency, repeatability, and integration.

Traditional cleaning methods

For decades, manufacturers have relied on media blasting and chemical cleaning:

- Media blasting: This method removes rust, paint, and oxides effectively, but it creates large volumes of dust and waste. Achieving consistent surface roughness, or surface energy levels, in preparation for painting or adhesive can be challenging. Nozzle wear leads to uneven cleaning and abrasive media leads to machine degradation. Disposal of used media adds to environmental and cost challenges.

- Chemical cleaning: Chemical processes can be expensive and restricted by stringent compliance measures. The need for tanks, chemical replenishment, and chemical handling pose safety and environmental hazards, and immersion in chemical baths does not allow for nuanced, selective cleaning and can strip away complex geometries.

While both methods work, they resist full automation due to consumables, variability and complexity.

TRUMPF laser cleaning and surface structuring

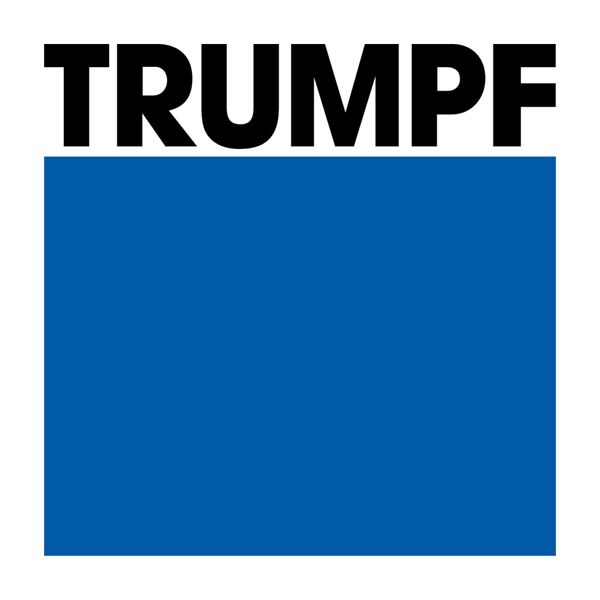

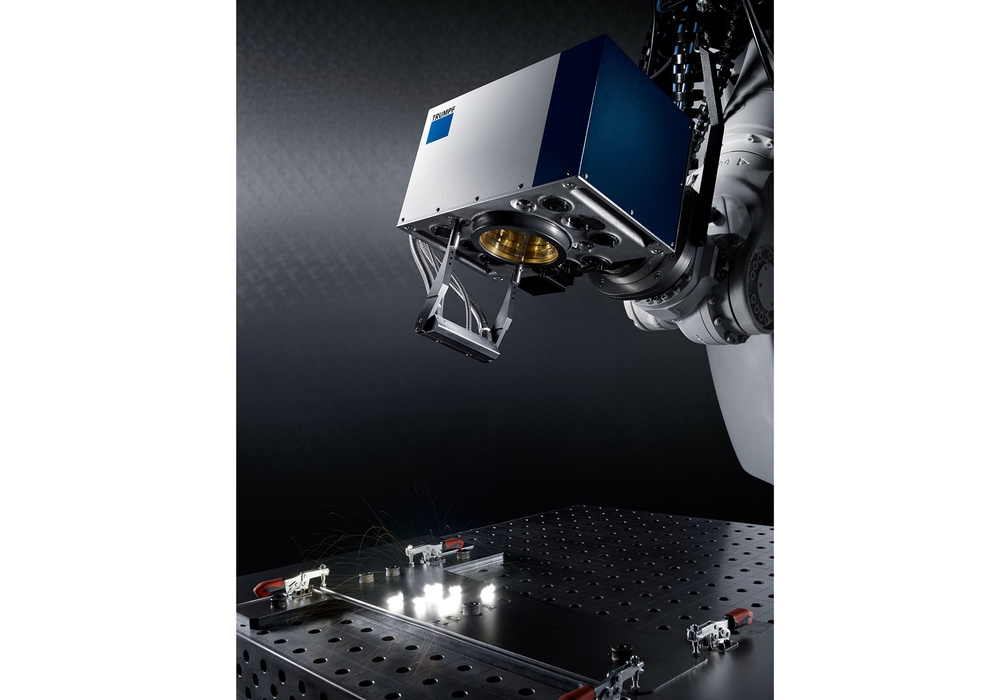

TRUMPF laser technology uses high-intensity pulsed beams to ablate oxides, coatings, and contaminants without damage to the underlying substrate. The process is dry, accurate, and digitally controlled, making it easy to integrate with robotic arms, CNC machines, or conveyor-based systems. From automotive and aerospace to energy, electronics, and defence, laser cleaning delivers unmatched flexibility for modern applications where precision and consistency are critical.

Key benefits of automated laser cleaning

Precision and control: Unparalleled precision, where digital parameters are set to achieve consistent, repeatable results, an essential factor for automated workflows.

Seamless automation integration: TRUMPF laser cleaning is designed for Industry 4.0 environments. Robotic arms can direct laser beams with pinpoint accuracy, and ‘on-the-fly’ cleaning allows surfaces to be prepared on continuous production lines without a fulltime operator.

Efficiency and cost savings: With no consumables such as abrasives or chemicals, laser cleaning dramatically reduces operational costs. There are fewer stoppages for replenishment, less maintenance, and greater predictability in process costs. Over time, the return on investment (ROI) in automated laser cleaning systems can be significant, especially for high-volume manufacturers.

Safety and compliance: Laser cleaning minimises operator exposure to hazardous dust and chemicals. Enclosed systems with high-quality dust extraction meet stringent workplace health and safety standards, helping manufacturers remain compliant while protecting employees.

Sustainability: As environmental regulations tighten, laser cleaning provides a clear advantage. It generates no abrasive or chemical waste and supports ESG goals by enabling cleaner, greener production practices.

Real-world applications & automation examples

Laser cleaning is transforming production in many areas:

- Automotive: Robotic laser systems automatically remove rust, oil and contaminants before welding car body components.

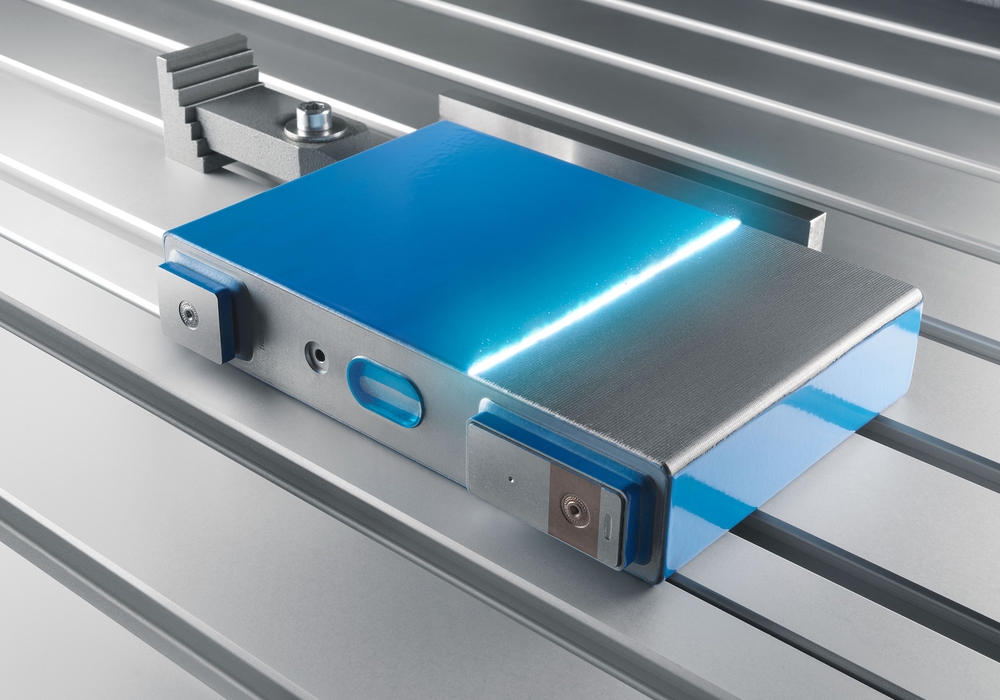

- Aerospace: Laser surface processing yields precise surface structures on titanium and aluminium parts, preparing them for bonding and ensuring flawless adhesion.

- Moulds, dies & tooling: Removal of material build-up and contamination on moulds and dies is critical to maintaining part quality, with a process that protects high-value, high-tolerance surfaces.

Conclusion

Laser cleaning is more than just a cleaning technology; it’s a powerful enabler of automated, efficient, and sustainable manufacturing. By eliminating consumables, streamlining automation, and improving safety, it represents the future of surface preparation. Manufacturers ready to modernise their production lines should explore TRUMPF’s TruMark and TruMicro laser cleaning solutions as cornerstone technologies for the next era of smart, automated manufacturing.

Ready to explore a cleaner, safer surface preparation solution for your operation’s needs?

Headland helps manufacturers move to the next generation of surface preparation. Our advanced manufacturing and TRUMPF experts can review your production needs and match you with the right TRUMPF laser cleaning solution.