KraussMaffei boosts Mexico’s agricultural industry with sustainable logistics solutions in packaging

Discover how KraussMaffei helped transform eco-friendly packaging in Mexico’s logistics sector—read the full case study now.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

Timesavers International with over 80 years of experience. Timesavers International is the global specialist that offers the perfect results for any size of business when it comes to deburring, edge rounding, removing laser oxide and heavy slag, finishing and precision grinding of sheet metal. Timesavers’ launched their new solutions for efficient deburring and consistent results at this year’s EuroBLECH.

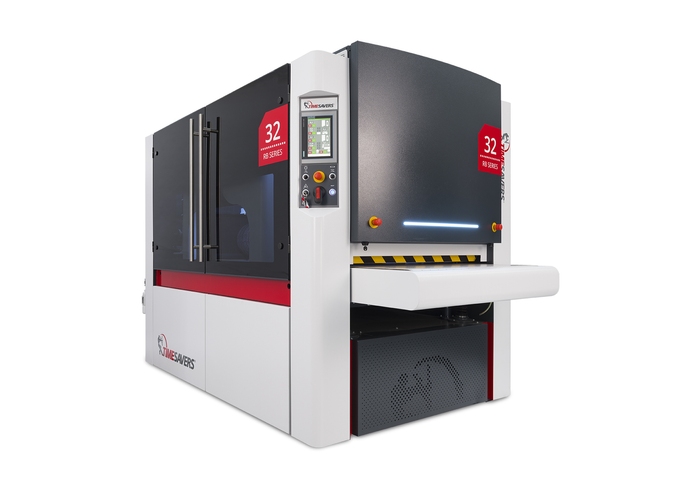

The Timesavers 32 HWRB series rotary brush machine is the latest and most advanced version of the compact machine. Not only has the rotary brush carousel been optimised, but the machine also has an additional feature: the Hammerhead. The popular rotary brush technique is the ultimate solution for creating a uniform radius on all edges of sheet metal parts up to a width of 1100 mm. It is even possible to combine edge rounding with the removal of oxide skin on steel parts. The 32 series HWRB will be equipped with a dust extractor (Timesavers x Absaugwerk) to ensure efficient deburring.

Another highlight from EuroBLECH, Timesavers presented the 22 RB series with pictogram control. This machine has a working width of 600 mm and is an even greater solution for companies that manufacture on a smaller scale. The results are perfectly deburred and rounded parts. The 22 RB series is the most compact model in our rotary brush machine range for deburring, edge rounding, finishing and laser oxide removal of various sheet metal parts.

Not missing at this year’s show was the large 42 RB series with its industry 4.0 functionalities and a must-to-be displayed at events like EuroBLECH. This machine is the largest deburring machine, available with a working width of 1350 and 1600 mm. The two grinding belts at the beginning of the machine, it is a huge solution for removing large burrs. The machine can also create a radius of 2 mm on parts with the eight rotary brushes, to ensure the quality of coating and painting.

Timesavers’ deburring machines from the 12 series have been the standard in the metal industry for more than forty years. With a starter model like the 12 series WB with a 600 mm working width for deburring and ideal for finishing small parts. Thousands of these economically attractive deburring machines are being used worldwide for the deburring and finishing of small parts. Understanding that this machine has an abrasive grinding belt and brush.

Timesavers also introduced the 10 series Manual Grinder, meaning you can finally find the entry-level model deburring machine you may need. This solution is 3 to 4 times faster than deburring by hand. Processing products is a lot more fun to do with this machine due to its ease of usage.

The Headland team is looking forward to helping you find the right solution that fits your production process.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

The Timesavers 10 Series deburring machine is a versatile and capable starter linishing machine. A cost-saving alternative to manual deburring, rounding edges and finishing your sheet metal.

The Timesavers 12 Series is a dry working deburring machine that can be equipped with an abrasive belt, disc or both. Deburr a huge variety of metals including copper, aluminum, stainless steel and mild steel.

The Timesavers 22 Series Deburring and Linishing Machine is perfect for dry finishing and metal deburring. A highly versatile machine it comes in three widths: 900 mm, 1050 mm, 1280 mm.

The Timesavers 32 series deburring machine is suitable for a wide array of metal parts. This linishing machine is compact and perfect for deburring, edge rounding, and finishing metal parts.

The Timesavers 42 series deburring machine is a superior solution for perfect finishing of metal cut parts. The 42 RB series ensures a high-end and smooth finish. Available in 1350 mm and 1600 mm width.