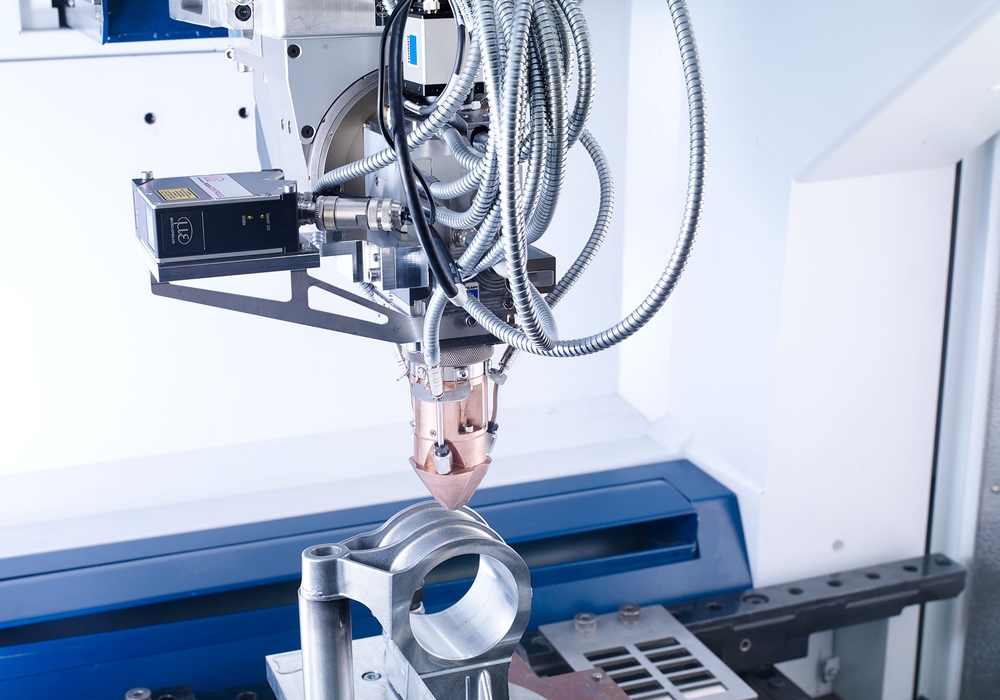

3D Laser Metal Deposition (LMD) represents a transformative advancement in additive manufacturing, offering unprecedented capabilities for creating complex metal components with exceptional precision and material properties. For Australian and New Zealand manufacturers facing unique geographical challenges and competitive pressures, laser cladding combines the flexibility of 3D printing with the strength and durability of traditional metalworking, opening new possibilities across multiple industries.

Applications across industries: ANZ success stories

Mining and resources: Australia’s mining sector utilises LMD technology for on-site repair of critical equipment, including excavator buckets, crusher components, and conveyor systems. Traditional repairs require shipping heavy components thousands of kilometres, resulting in extended downtime and massive costs. TRUMPF’s LMD technology can enable on-site repairs that can restore equipment to better-than-original condition.

Energy sector: Both countries’ renewable energy industries require specialised components for wind turbines, solar tracking systems, and geothermal equipment. TRUMPF’s LMD technology enables the repair of expensive components and the creation of parts with enhanced performance characteristics, crucial for maintaining energy infrastructure in remote locations.

Marine and offshore: Australia and New Zealand’s extensive maritime industries face unique challenges with saltwater corrosion and remote operating conditions. TRUMPF’s LMD technology enables the production of corrosion-resistant components and repairs that can extend equipment life and reduce maintenance costs.

Aerospace and defence: New Zealand’s growing aerospace industry and Australia’s defence manufacturing sector require the ability to repair components to the highest level, manufacturer-approved standards. TRUMPF’s LMD technology provides the material properties, consistency, and precision for qualified aerospace processes.

TRUMPF’s technological leadership: The solution ANZ manufacturers need

TRUMPF has emerged as the leading innovator in LMD technology, contributing significantly to the advancement of the field through several key developments that directly address the challenges faced by Australian and New Zealand manufacturers.

Advanced laser systems

TRUMPF’s high-power fiber lasers provide the precision and power density required for effective metal deposition. Their lasers offer exceptional beam quality and stability, enabling consistent layer formation, superior metallurgical bonding and flexibility to accommodate low speed and high speed deposition applications.

Integrated processing solutions

TRUMPF’s TruLaser Cell series combines LMD capabilities with 3D laser cutting and welding in a single system, enabling true hybrid manufacturing. This integration allows manufacturers to cut and weld material in 3D and selectively enhance surfaces with LMD. This capability is particularly valuable for ANZ manufacturers who need flexibility in a dynamic, job-shop environment and can benefit from multiple process capabilities on a compact footprint.

Process monitoring and control

TRUMPF has developed sophisticated monitoring systems that use real-time sensors to track melt pool characteristics, powder flow rates, and thermal conditions. These systems enable closed-loop control of the deposition process, ensuring consistent quality and reducing defects. For quality-conscious ANZ manufacturers competing in global markets, this level of process control is essential for maintaining competitiveness.

Software integration

TRUMPF’s TruTops software suite provides comprehensive process planning and optimisation tools specifically designed for LMD applications. This includes automated path planning, parameter optimisation, and quality prediction algorithms. This software sophistication helps ANZ manufacturers overcome the skills gap and achieve world-class results.

Conclusion: The strategic imperative for ANZ manufacturers

3D Laser Metal Deposition has evolved from a simple repair process to a sophisticated manufacturing technology that is reshaping the design and production of complex metal components. For Australian and New Zealand manufacturers facing unique geographic and competitive challenges, TRUMPF’s LMD technology is not just an advantage—it’s a necessity for survival in the global market.

Are you ready to future-proof your manufacturing?

The question isn’t whether TRUMPF’s LMD technology will transform your business—it’s whether you’ll be leading the transformation or watching your competitors pull ahead. Contact our Headland and TRUMPF experts and discover how LMD technology can turn your manufacturing challenges into competitive advantages.