Changing manual manufacturing: Operator augmentation with InspecVision’s GAV System

Read how InspecVision’s breakthrough system doesn’t replace workers—it gives them X-ray vision and a photographic memory.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

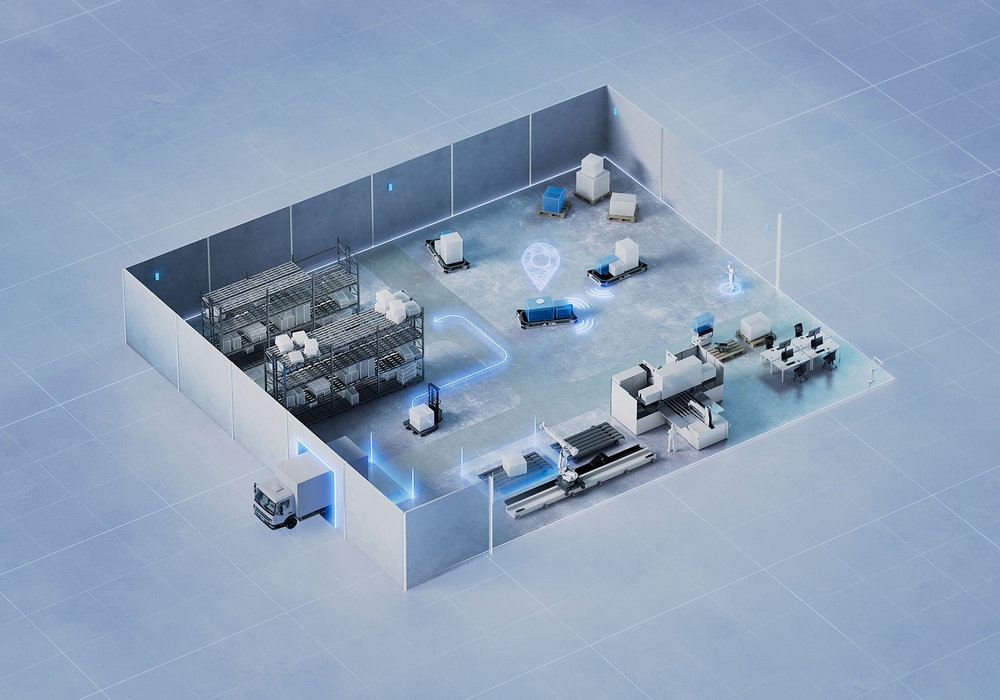

TRUMPF has expanded their partnership with STOPA to create new opportunities for collaboration. The two companies recently announced an agreement to work even closer together in the future. STOPA’s automated storage solutions are used in a variety of settings, including TRUMPF’s smart-factory solutions. STOPA systems enable customers to load and unload their machines automatically and to link machines together to form logistics networks. This boosts productivity on the shop floor by significantly reducing non-productive time.

Thanks to their versatile design, STOPA storage systems are perfect for modern smart-factory production environments or integrated seamlessly into existing factories. Their benefits come to the fore when combined with TRUMPF’s new Oseon software, which is designed to make production planning and control even simpler, up to and including fully automated automation of the sheet-metal fabrication process. TRUMPF believes that partnerships and open standards are the keys to developing and enhancing its smart-factory solutions. These include open interfaces from umati (universal machine technology interface) and open-locating standards from omlox (an open standard for a precise real-time indoor localisation system). It enables interoperability and flexibility for different trackable providers as well as TRUMPF’s existing partnerships with intralogistics specialists.

TRUMPF recently brought all its different smart-factory solutions businesses under one umbrella with the goal of fuelling further growth. STOPA was founded in Achern, Germany in 1963. Currently employing some 370 people, the company specialises in automated storage systems for sheet-metal and long-span materials as well as fully automated parking systems. Michael Stolzer, managing partner of STOPA Anlagenbau GmbH says:

“After working together for more than 35 years, we’re excited to take the next step and work together even more closely,”

Till Küppers, CEO of Trumpf Machine Tools, emphasises the companies’ joint ambitions:

“Our goal is to create a strong foundation for continuing to grow our successful partnership and to bring our smart-factory solutions to even more businesses around the world.”

The expanded partnership between TRUMPF and STOPA will enable Headland Technology to offer our customers an even more comprehensive range of efficient, sustainable, and productivity-enhancing solutions in the future.

Headland Technology can help you streamline your operations and get ahead of the competition. Our smart factory specialists can support and help you find the best solutions for your business. Contact us today to learn more.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

TRUMPF’s OSEON software enables users to synchronise material flow throughout their production schedule. Learn more about Oseon.

Automated Warehouse Storage for sale in Australia and New Zealand. Hanel and STOPA storage systems.