Changing manual manufacturing: Operator augmentation with InspecVision’s GAV System

Read how InspecVision’s breakthrough system doesn’t replace workers—it gives them X-ray vision and a photographic memory.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

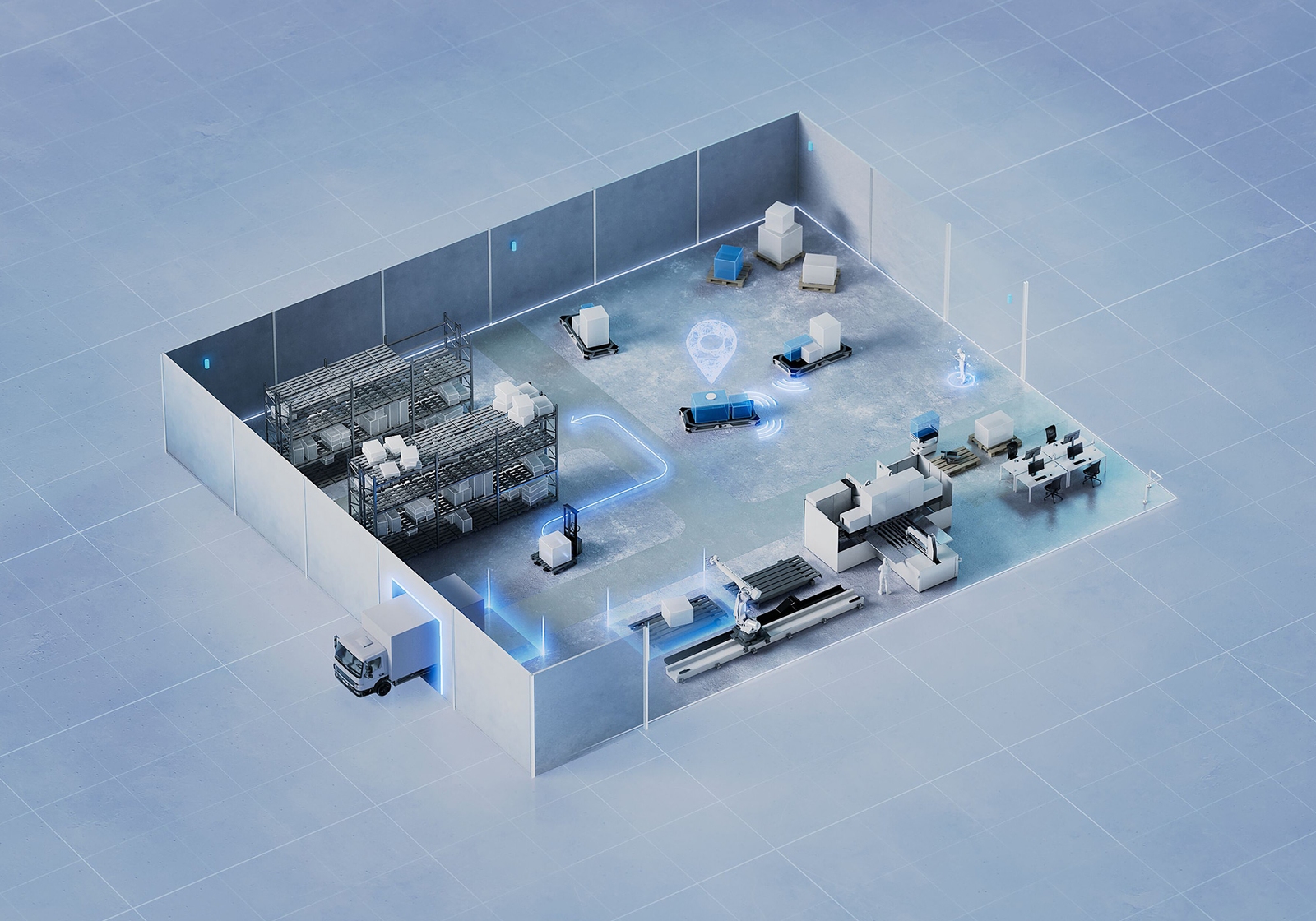

OSEON software enables users to synchronise material flow throughout their production schedule.

First the user needs to load their production schedule with OSEON taking over the production schedule automatically.

The software obtains continual updates on the production status of each machine on the shop floor. Additionally, it stores information on material stocks, the location of carts and the parts that are required for each job.

Barcodes and smart docking stations manage the flow of materials. With hand-held scanners the pallet is scanned for the next part of the process. This can also be automation with the use of Automated Guided Vehicles (AGV).

The software alerts either free AGVs or users with carts to ensure the material required for each job is always there as required.

The new condition monitoring service enables technicians to detect problems before they occur. it can detect temperature or pressure issues before they impact production. The app sends the users notification emails with suggested solutions.

With its open interface this software is suitable for smart factories through to shops that are starting on their digital production journey.

Our software application experts will be happy to organise a consultation to better understand your needs and recommend an appropriate solution.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.