Spain’s Oxiplant, a leading steel service centre, has built its reputation on precision, reliability, and fast turnaround for customers in industries ranging from shipbuilding to renewable energy. As demand for thicker, high-quality steel parts continues to grow across Europe, the company faced mounting pressure to expand its capabilities without compromising on quality. To address this challenge, Oxiplant invested in the TECOI TEKNOS oxyfuel-cutting system, designed to deliver superior output, flexibility, and efficiency in large-format steel processing.

About Oxiplant: Oxiplant is an innovative company with extensive knowledge and experience in the steel processing sector. It specialises in the cutting, transformation, and sale of metal products, from industrial panels to metal tubes and sections. Serving clients across multiple industries, including boiler making, machining, structural steel fabrication, shipbuilding, automotive, and renewable energy. Oxiplant has established a strong reputation for precision, reliability, and high-quality output. More about Oxiplant

Challenge

Across Europe, the demand for thicker, precision-cut steel has risen sharply, especially in industries such as marine, construction, and renewable energy. Oxiplant faced operational bottlenecks in processing large-format, high-thickness parts. The limitations of its existing machinery led to higher production costs and slower turnaround, risking both competitiveness and delivery commitments to clients.

Solution

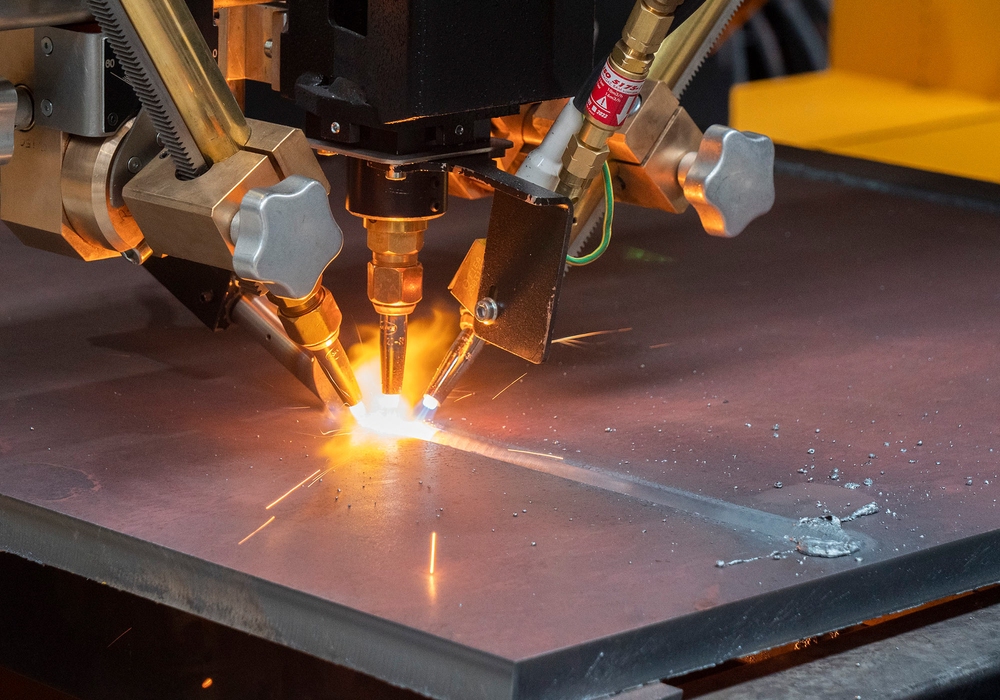

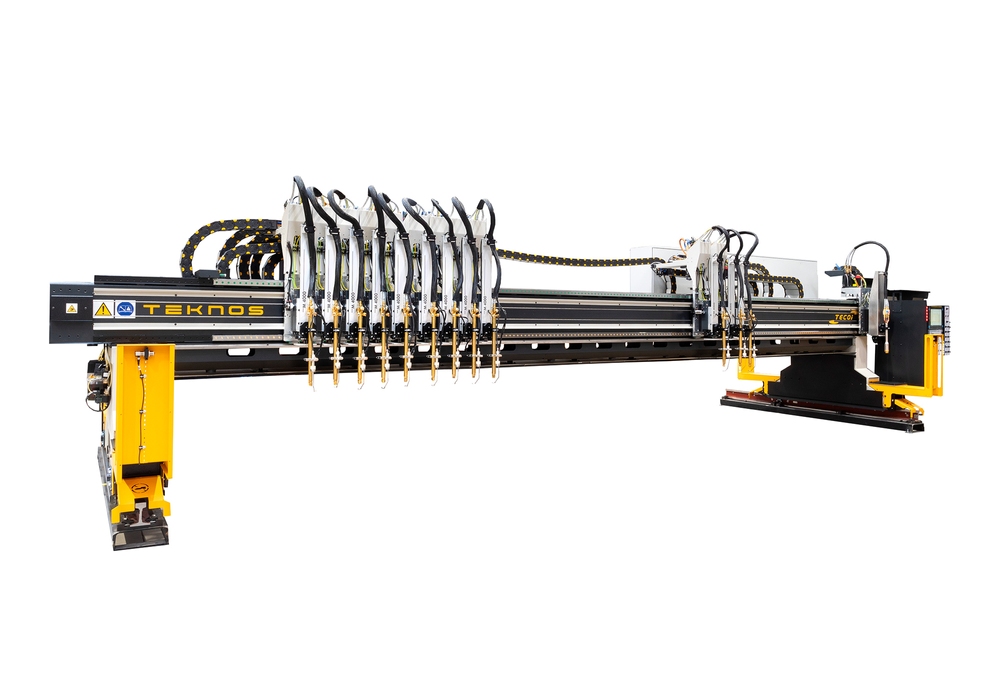

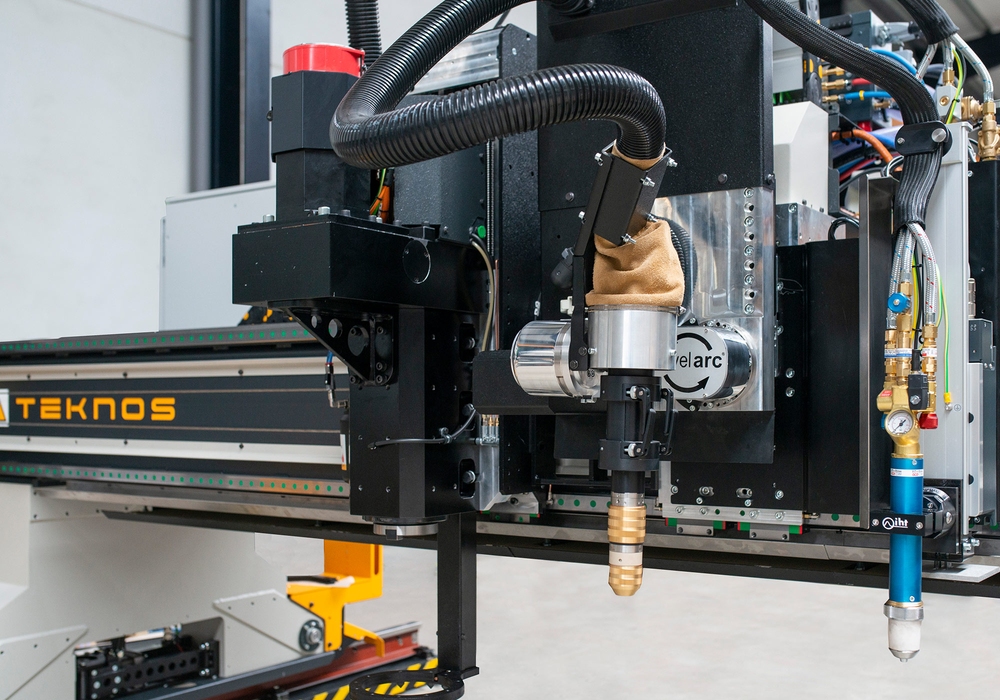

Oxiplant partnered with TECOI to integrate the TEKNOS oxyfuel-cutting system, specifically engineered for mass processing of thick steel plates.

- 12 independent torches deliver simultaneous cuts, accelerating production output.

- A 7m x 24m working area enables processing of oversized sheets in a single setup, eliminating multiple handling steps.

- Advanced TECOI engineering ensures consistent high-definition cuts while reducing scrap and rework.

Implementation

The TEKNOS was installed at Oxiplant’s northern Spain facility within days of the commissioning period. Initial challenges around synchronising multiple torch heads were resolved through TECOI’s in-house calibration expertise. Operators received more than 40 hours of training covering oxyfuel processes, software, and machine optimisation.

“Thanks to this new TEKNOS from TECOI, we have increased our work capacity, optimised costs and reduced times to the minimum,” Oxiplant stated. “In addition, we continue to guarantee our customers their quality requirements and high-definition work for their most demanding jobs.”

Results

- Processing capacity increased, enabling larger-volume contracts

- Delivery times cut, ensuring faster customer turnaround

- Operational costs reduced, while maintaining quality standards across thick-plate jobs

Oxiplant plans to expand its fleet further with additional TECOI models to strengthen its leadership in high-capacity steel processing.

Are you specialising in structural steel fabrication, shipbuilding, metal processing, or any industry that requires precision cutting of metal using oxyfuel, plasma, or laser technology?

Contact our TECOI experts to discuss how we can help your business achieve faster, more precise cutting with oxyfuel, plasma, or laser technology. Schedule your free consultation and cut smarter.