For Spaten-Franziskaner-Bräu, a historic beer brand under the Anheuser-Busch InBev umbrella, maintaining the highest quality standards is essential. A key part of this commitment is the precise storage and monitoring of beer samples from freshly brewed batches—ensuring consistency, efficiency, and adherence to strict quality control protocols. To achieve this, Spaten-Franziskaner-Bräu relies on Hanel automated storage solutions, which streamline operations and maintain optimal conditions for sample management.

This dedication to quality is deeply rooted in the German Reinheitsgebot (Purity Law), one of the world’s oldest and most respected brewing regulations. Enacted in 1516, the Purity Law originally applied to Bavaria and later became the national standard, ensuring that only water, malt, hops, and yeast are used in brewing. More than 500 years later, its principles continue to define German beer production, reinforcing the industry’s unwavering commitment to purity and excellence.

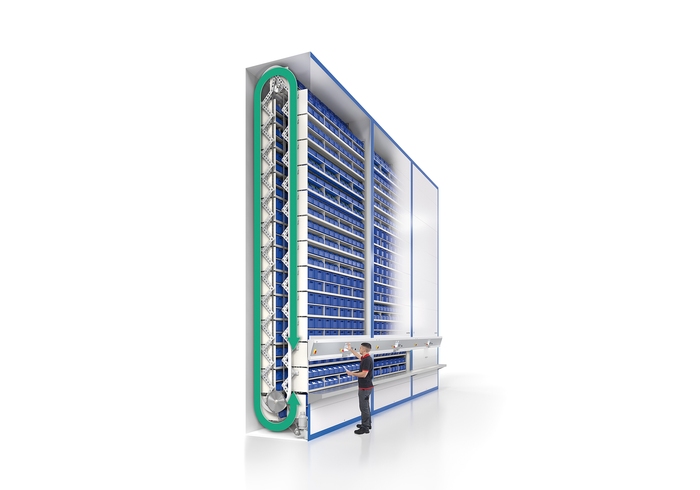

This case study explores how the brewery leveraged the Hänel Rotomat to streamline operations, enhance quality control, and uphold its reputation for exceptional beer craftsmanship.

About Spaten-Franziskaner-Bräu: Spaten-Franziskaner-Bräu is a brewery in Munich, Germany, with a history dating back to 1397. Since 1922, they have been one of Germany’s most prestigious breweries, rooted in history and known for producing superb beers that reflect the rich heritage of Bavarian brewing. Spaten-Franziskaner-Bräu, as part of the Anheuser-Busch InBev group, contributes to the world’s largest brewing group by producing classic beers that are popular both locally and globally.

With a centuries-long heritage, the brewery remains committed to combining traditional brewing processes with modern innovation. The brewery, known for its Spaten and Franziskaner brands, maintains strict quality standards to ensure that each batch fulfils the expectations of beer fans around the world.

Challenge

Spaten-Franziskaner-Bräu, a division of Anheuser-Busch InBev—the world’s largest brewing corporation recognised for its classic beer brands such as BECK’S, STELLA ARTOIS, Corona, and Budweiser—produces millions of hectolitres of beer annually. Spaten-Franziskaner-Bräu, headquartered in Munich, maintains stringent quality control standards. The goal was to efficiently store and monitor beer samples from freshly made batches in a laboratory setting. These samples required certain conditions, such as a steady temperature, to ensure reliable microbiological analysis over time. The brewery required a space-saving, energy-efficient, and ergonomic solution to suit their stringent quality control systems.

Solution

To address these requirements, Spaten-Franziskaner-Bräu implemented a temperature-controlled Hänel Rotomat vertical lift system in their quality management laboratory. The Hanel Rotomat is renowned for its ability to optimise storage space while maintaining controlled environmental conditions essential for sensitive materials.

Key features of the solution included:

- Temperature consistency: The Hanel Rotomat was equipped with an advanced electronic heating unit, ensuring a stable internal temperature of 28°C—critical for preserving the microbiological fermenting process.

- Ergonomic design: The vertical lift system allowed for easy access to stored beer samples, reducing strain on laboratory personnel and increasing operational efficiency.

- Energy efficiency: The Hanel EcoLoad feature continuously monitors load distribution, providing real-time recommendations to optimise energy consumption during system operation.

Implementation

The integration of the Hanel Rotomat into Spaten-Franziskaner-Bräu’s laboratory operations was seamless:

- System installation: The Rotomat was installed within the quality management laboratory, configured to meet the brewery’s specific storage and temperature requirements.

- Calibration: The electronic heating unit was fine-tuned to maintain the precise 28°C temperature needed for accurate sample monitoring.

- Load optimisation: The EcoLoad system provided guidance on the strategic placement of beer samples within the storage carriers, ensuring balanced weight distribution for energy-efficient operation.

- Training and workflow integration: Laboratory staff were trained on the ergonomic handling of the Hanel Rotomat, enabling them to access and monitor samples quickly and safely.

Results

The Hanel Rotomat delivered significant benefits to Spaten-Franziskaner-Bräu, including:

- Improved quality control: Consistent temperature conditions ensured reliable microbiological monitoring of beer samples.

- Space optimisation: The compact vertical design of the Hanel Rotomat freed up valuable laboratory space, allowing for better utilisation of the facility.

- Energy savings: The EcoLoad feature minimised energy consumption, supporting the brewery’s sustainability goals.

- Enhanced workflow: Ergonomic processes reduced manual effort, increasing overall efficiency in sample handling.

By adopting the Hanel Rotomat system, Spaten-Franziskaner-Bräu upheld its commitment to producing premium-quality beer while streamlining laboratory operations. This solution not only supported the brewery’s traditional values but also reinforced its position as an innovative leader in the beverage manufacturing industry.

Conclusion

For Spaten-Franziskaner-Bräu, the integration of the Hanel Rotomat system has been a game-changer, revolutionising the way beer samples are stored and monitored in their quality management laboratory. With its compact design, precise temperature control, and energy-efficient operation, the Hanel Rotomat optimises laboratory workflows and supports the brewery’s commitment to upholding the highest standards of quality and sustainability.

Spaten-Franziskaner-Bräu has demonstrated how breweries can modernise their operations without compromising their heritage or product excellence by seamlessly combining tradition with innovative technology.

Are you part of the brewing or beverage manufacturing industry and looking to optimise space, comply with strict brewery regulations, and maintain high standards?

Take the next step. Reach out to our Hanel experts and learn how our Hanel’s storage systems can enhance your brewery’s efficiency, sustainability, and quality.