Compact, flexible, and more efficient: TRUMPF unveiled a new solution for machine interlinking

Discover how TRUMPF is redefining sheet metal automation with a smarter, more flexible interlinked production system.

Log in to MyHeadland – your new customer portal | No access yet? Email marketing@headland.com.au

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

Netstal and KraussMaffei are technology leaders in the injection moulding machine space. Renowned for their high speed, precision, flexibility and long lifespan, these machines will get the job done regardless of the injection moulding application.

Whether your moulding preforms, closures, packaging, medical equipment or any other moulded product we will help you find the right machine for your exact needs. For sale Australia and New Zealand wide.

These injection moulding machines are used across automotive, packaging, food & beverage, electronics, pharmaceuticals, medical, construction and a variety of other industries.

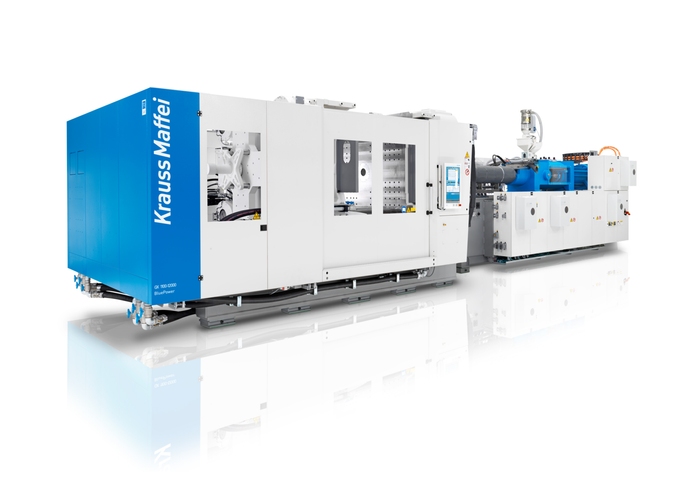

Krauss Maffei’s fully hydraulic CX series plastic injection moulding machine offers outstanding compactness, efficiency and flexibility.

KraussMaffei’s basic injection moulding machine, precisionMolding is the perfect entry-level solution for all-electric injection moulding to react quickly and innovatively to market demands.

KraussMaffei’s GX Series plastic injection moulding machine comes equipped with a first-class hydromechanical dual platen in conjunction with a single-piston injection system.

KraussMaffei’s PX series plastic injection moulding machine is the answer to your requests for more flexibility while increasing productivity.

KraussMaffei’s MX Series plastic injection moulding machine is recognized around the world and is principally characterized by the hydro-mechanical dual platen clamping unit, which they developed themselves

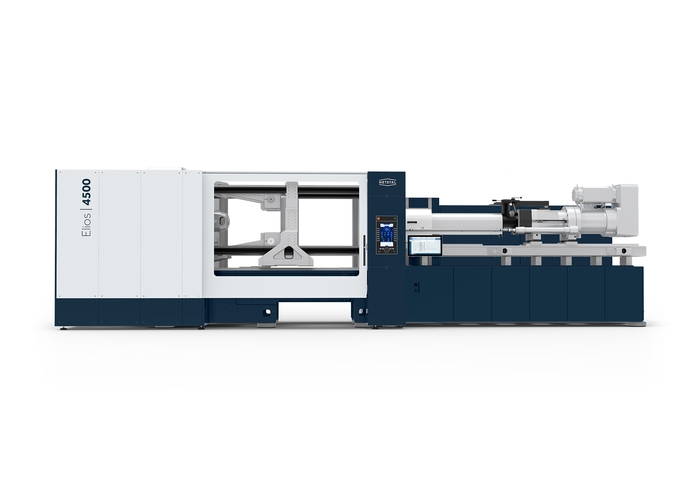

Strong, quick, accurate, energy-saving, and user-focused: The Elios Series creates new standards for high-performance injection moulding with its cutting-edge drive technology.

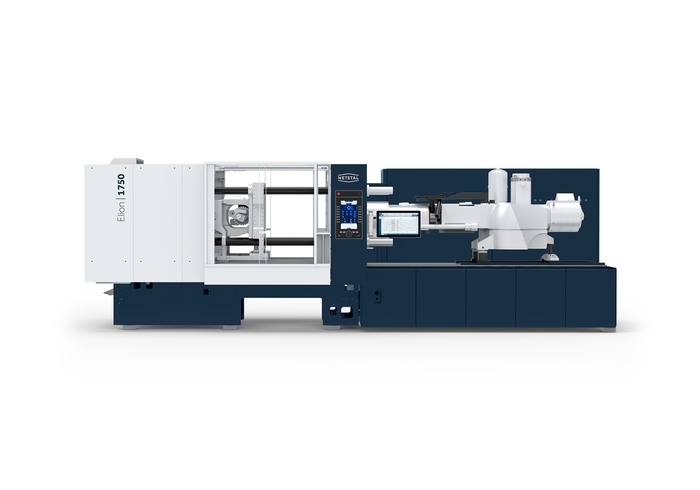

The most crucial features of the Elion series are its speed, accuracy, dependability, user-friendliness, and operational efficiency. “Low energy, high performance” is our motto.

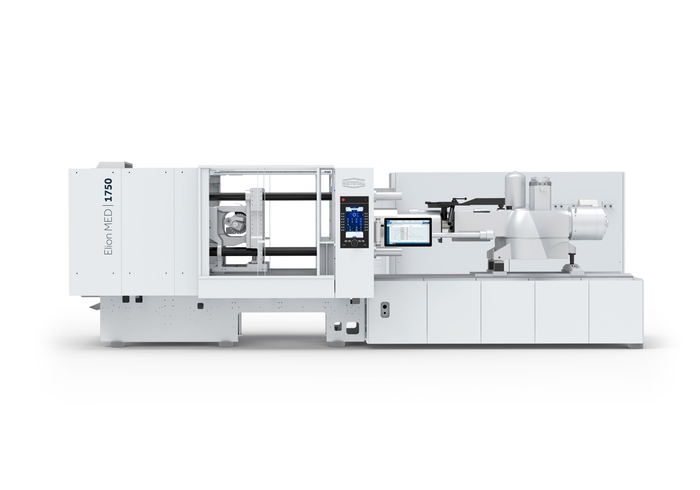

The Elion MED injection moulding machines are the most widely used core element of complex production lines for pipettes, petri dishes, insulin pens, and all other plastic parts in medical technology.

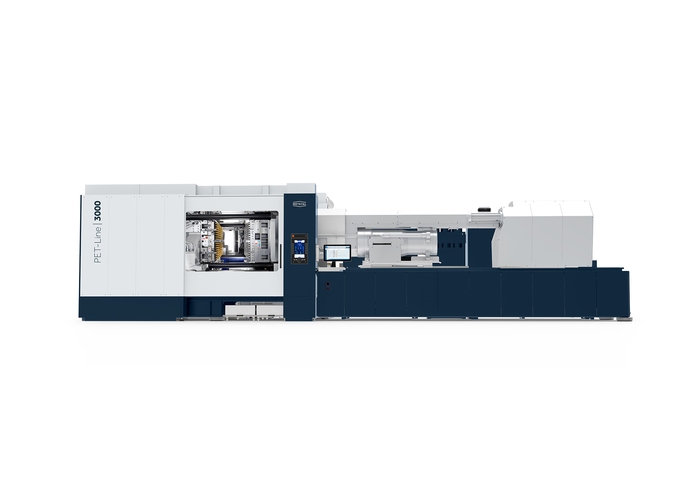

With full compatibility with existing side-entry moulds and after-cooling stations, the first Netstal PET system with lateral removal is available.

We can help find the right injection moulding machine for your factory’s needs. Please fill out the form and our plastic machinery specialist will get in touch with you.

In addition to supplying you industry-leading manufacturing equipment, we provide machine servicing, software support and smart manufacturing consulting for all our brands.