Compact, flexible, and more efficient: TRUMPF unveiled a new solution for machine interlinking

Discover how TRUMPF is redefining sheet metal automation with a smarter, more flexible interlinked production system.

Log in to MyHeadland – your new customer portal | No access yet? Email marketing@headland.com.au

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

Headland recently caught up with Mathew Galea from MJG Stone to learn how they’ve leveraged water jet cutting technology to help them safely and quickly manufacture their premium stone products.

MJG Stone was established in 2019, although the ownership team are experienced professionals that have been in the industry for over 20 years. Their focus is on premium products with high quality service. They work with materials such as, natural marble and granite, engineered stone and wide format porcelain to create benchtops, vanities, floor and wall coverings.

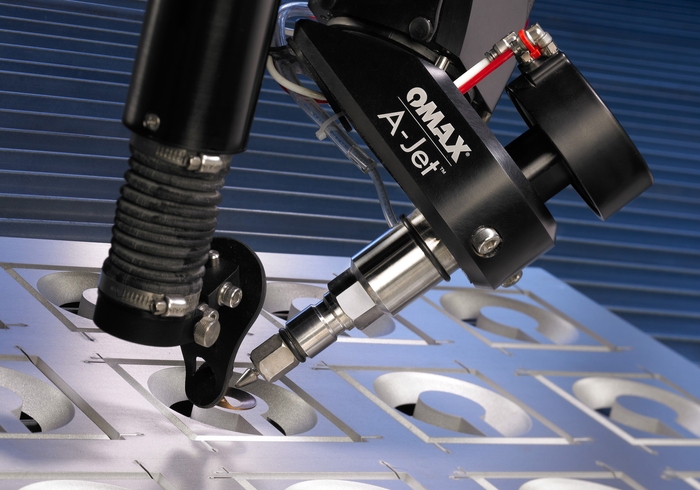

“MJG Stone specialise in the high-end of the residential market. Our team have many years of experience in the industry coupled with specialised hi-end machinery such as our new 5 axis OMAX MAXIEM waterjet cutting machine which allow us to deliver a first class product” says Galea.

MJG Stone’s growth has been steady over the last two years, with COVID having a positive effect on their business.

“There has been an increase in home renovations since the pandemic, I suspect with people spending more time at home they are finding out what needs to be improved to make their home more liveable”, says Galea.

“You need skilled staff that are passionate about what they do, however, you also need the right technology and know how to use it properly. At MJG Stone we are so fortunate to have a group of like-minded and experienced individuals with a focus on quality and high levels of customer service”.

“With any new piece of technology, we invest in, it has to be reliable. We do a lot of research and ensure we are buying quality equipment. Whatever we buy, it must have local technical support. It’s vital to keep our machines up and running to continue to meet deadlines and produce excellent products and provide great service to our clients, says Galea.

“Due to the market we search, we are constantly called upon to create faceted curves and porcelain/dekton benchtops. Having a 5-axis waterjet cutting machine in-house allows us to control our production line internally without the need to outsource or create stone pieces by hand.

“We have one 3-axis water jet machine. The 5-axis will be our third in house water jet cutting machine. It’s a safe way of machining stone, with the water helping minimise dust and enabling us to be Silicosis compliant”.

We have loved using the 3-axis MAXIEM water jets over the last 10-15 years. Buying a new 5-axis OMAX Maxiem was an easy choice, based on our previous experience with the brand” Galea says.

“We are a full-suite stone fabricator, so we use a combination of bridge saws, line polishers and CNC routers. Each piece of machinery has its place and certain brands in our experience are better at certain tasks. In our opinion, OMAX MAXIEM’s are the best waterjets out there” Galea says.

“Reliability and backup service are the main aspects of machinery we rely upon and create one of the main decision making factors when buying a new piece of machinery. Our machines are running night and day 6 days a week non-stop. We cannot have machines down and if they do go down, we need them back up and running without delay. We run tight deadlines and a tight shop, so we need machinery that will perform”, Galea says.

“On the rare occasion that we have had an issue with our OMAX Waterjet Cutter we have been able to sort the issue in-house with the support of Headland. The OMAX units are simple to fix which allows us to do most maintenance and repairs ourselves. We are confident that when needed Headland are capable of solving any issues without delay”, Galea says.

The stone benchtop industry has been strong for some years now. There are new products continually entering the market which is taking market share away from laminate and solid surface. stone or porcelain are now the norm for any new kitchen.

If you’re interested in discussing our range of OMAX Waterjet Cutting Machines including the MAXIEM machines discussed above Enquire Now.

OMAX’ high performance water jet cutting machines are capable of cutting composites, metals, stainless steel, aluminium, titanium, copper, brass, glass, stone, concrete, ceramics, foam and rubber.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

Water jet cutting machines for sale in Australia. Our water jets can cut steel, stone, glass, rubber, plastic & more.

This range of abrasive water jet cutting machines can cut virtually any material of any thickness quickly and efficiently, maximising production and profitability.