KraussMaffei boosts Mexico’s agricultural industry with sustainable logistics solutions in packaging

Discover how KraussMaffei helped transform eco-friendly packaging in Mexico’s logistics sector—read the full case study now.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

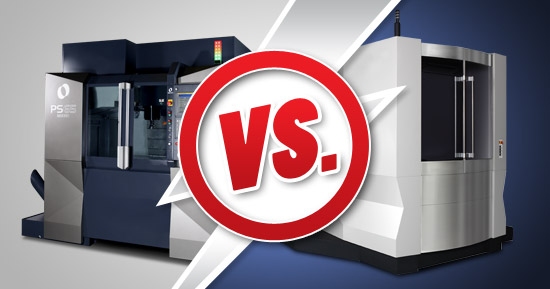

Horizontal and vertical are the two basic kinda of machining centers. Whether a machining center is horizontal or vertical refers to the main spindles orientation. Both the horizontal and vertical machining centers range from small, bench-mounted devices to a room-sized machine.

Horizontal machining centers have x – y table with a cutter mounted on a horizontal arbor across the table. Most horizontal machining centers highlight a =15/-15 degree rotary table allowing one to mill at shallow angles. Horizontal machining centers are often used to mill grooves and slots. It may also be used to shape flat surfaces.

Vertical machining centers have its spindle axis vertically oriented. Its milling cutters are held in the spindle and it rotates on its axis. Generally, the spindle could be extended to allow plunge cuts and drilling, although the table could also be lowered or raised. The vertical machining centers have two subcategories. These categories are the bedmill and the turret mill.

Although they may be similar since both are machining centers, vertical and horizontal machining centers serve different purposes. Horizontal machining centers were first to appear to put milling tables under lathe-like headstocks. However, through the desire to change the angle of the horizontal machining centers, accessories such as add-on heads were created to convert the horizontal to vertical machining centers.

Horizontal machining centers work best with heavy work piece that needs machining on multiple sides. Die sinking on the other hand is best with vertical machining centers.

If you’re interested in discussing our range of CNC machines from Makino, Nakamura-Tome, Hyundai-WIA and Citizen spanning horizontal and vertical machining centers, lathes, milling machines & more Enquire Now.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.