Victoria University (VU) is one of Australia’s only dual-sector institutions, delivering both higher education and TAFE training across multiple campuses. To explore how the university is preparing the next generation of engineers and tradespeople, we interviewed Jack Gillson, TAFE Teacher – Fabrication & Welding at Victoria University.

At the Sunshine Trade Hub in Melbourne, Jack Gillson and his team focus on practical, industry-aligned training for apprentices and pre-apprentices, particularly within the fields of welding, heavy fabrication, sheet metal, fitting and machining. The goal: ensuring graduates are job-ready for the modern manufacturing and engineering sectors.

About VU (Victoria University): For more than a century, VU has established itself as a distinctive educational institution serving Melbourne’s western suburbs and the broader community with an unwavering commitment to accessibility and opportunity. What sets VU apart is its unique dual-sector model, being one of only six Australian universities to seamlessly integrate both TAFE and higher education pathways under one roof, creating an educational ecosystem where students can begin their journey at any level, from certificates and diplomas through to undergraduate degrees and postgraduate qualifications.

This flexible, ladder-like progression system removes traditional barriers to education, allowing students to chart their own course regardless of their academic starting point or life circumstances. VU’s innovative approach to learning and teaching reflects its strategic vision of fostering positive outcomes not just for individual students, but for the broader industrial landscape and community it serves, positioning the university as a catalyst for social mobility and economic development in one of Australia’s most dynamic regions. More about VU

The Challenge

VU’s engineering workshops had been equipped with traditional plasma cutting technology. While functional, the equipment was becoming dated and no longer aligned with industry best practice.

“We had a CNC plasma cutter, but the quality wasn’t where it needed to be to match current manufacturing standards,” explained Jack Gillson, TAFE Teacher in Fabrication & Welding. “As someone passionate about new technology, I saw a real opportunity when an advanced manufacturing grant became available.”

The challenge was clear: upgrade VU’s training capabilities to reflect modern industry technologies, attract more students, and give them exposure to advanced workflows used in today’s workplaces.

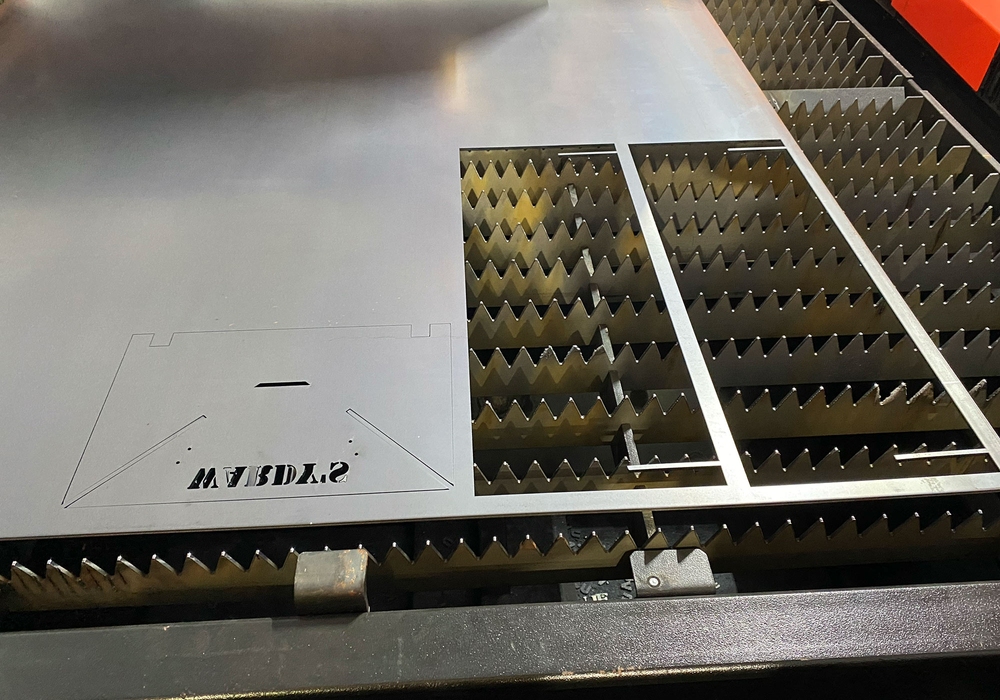

The Solution – JFY 3015 Laser Cutter

After consulting industry contacts and peers, Jack was introduced to Headland Technology by a colleague at Ringwood Secondary College. Following a tender process, VU selected the JFY 3015 laser cutting machine, powered by TRUMPF technology.

“Headland stood out,” said Gillson. “They were professional throughout the process, and I felt confident we’d receive strong after-sales support. The JFY solution was perfect, combining Headland’s high-quality technology with an accessible investment level for education.”

Implementation

Integrating the JFY 3015 required careful planning. Space was made by retiring an old guillotine machine, freeing up a highly visible location directly across from the main classroom.

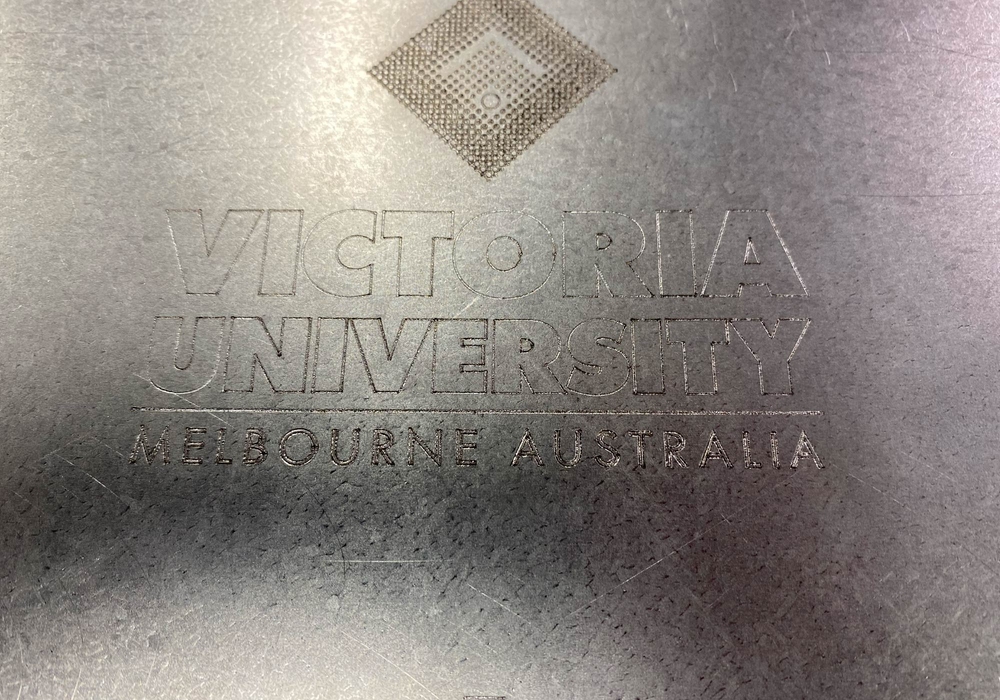

“The placement couldn’t have been better,” Jack Gillson explained. “It sits under our crane for safe handling, and right at the front of our training space – it makes the workshop look modern and cutting-edge.”

Training and installation were delivered smoothly, with additional follow-up training days available for staff to deepen their expertise.

Benefits and impact

The JFY 3015 has already transformed the learning experience for students at VU:

- Modern manufacturing training: Students now work on real-world workflows – from CAD design to precision laser cutting – mirroring industry standards.

- High precision & versatility: The machine delivers accurate results across multiple materials and thicknesses, a major upgrade from plasma cutting.

Student engagement:

“The laser cutter excites the students,” Jack Gillson said. “They love seeing their designs come to life with precision – it makes learning hands-on and inspiring.”

Cost & maintenance advantages: Unlike older plasma systems, consumables last longer, making the machine more efficient and cost-effective for TAFE budgets.

Jack believes the new technology gives VU a competitive edge in training:

“I haven’t seen many other TAFEs with a laser cutter of this size and capability. It sets us apart and prepares students for modern industry.”

Ongoing partnership with Headland

Headland’s responsiveness and service have been central to the success of the project.

“Working with Headland has transformed our training delivery, giving our students the tools and confidence to step straight into modern engineering workplaces,” said Gillson.

The relationship continues, with further training sessions planned and potential future investments in advanced manufacturing technologies such as CNC and robotics.

Looking ahead

Gillson is a strong advocate for integrating advanced manufacturing technologies into training environments:

“For Australia to stay competitive, we need to embrace automation, robotics, and smart manufacturing. Machines like the JFY 3015 allow us to show students exactly what that looks like.”

His advice for other institutions considering investment:

“Don’t hesitate. These machines are efficient, cost-effective, and deliver so much more than traditional equipment. For TAFEs especially, it’s a no-brainer over plasma cutters.”

Conclusion

Through its partnership with Headland, Victoria University has taken a major step forward in aligning its training with industry needs. The JFY 3015 laser cutter has become a centrepiece of the Sunshine Trade Hub, inspiring students and equipping them with the skills required for Australia’s future manufacturing workforce.

Are you considering upgrading your institution’s manufacturing technology to better prepare students for modern industry demands?

Headland Technology provides comprehensive advanced manufacturing solutions specifically designed for educational institutions. Our experts understand the unique challenges faced by universities and TAFEs when integrating cutting-edge technology into their training programs. From initial consultation and equipment selection through to installation, training, and ongoing support, our team can help you transform your workshops and give your students the competitive edge they need in today’s manufacturing landscape. Contact our metal fabrication and JFY experts to discover how we can help your institution achieve the same success as Victoria University.