CEO Update: A Message from George Yammouni

A strong finish to 2025 with rising PMIs, major service improvements underway, a new customer portal launched, and a positive, growth-focused outlook heading into 2026.

Log in to MyHeadland – your new customer portal | No access yet? Email marketing@headland.com.au

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

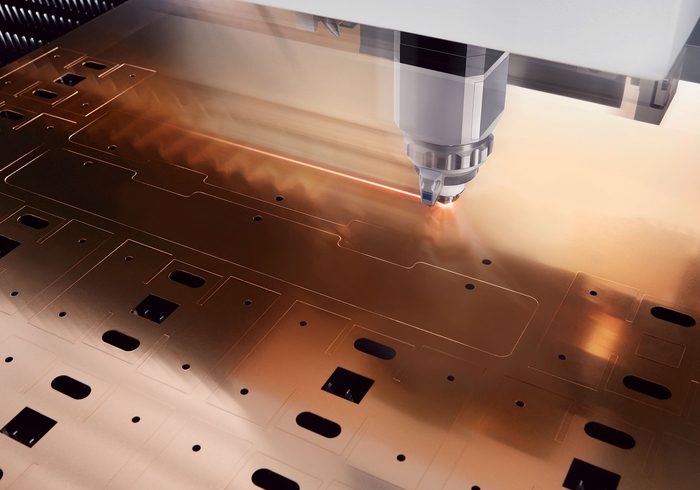

At EuroBLECH this year, CEO of TRUMPF Machine Tools Stephan Mayer expressed their commitment to helping with sustainable solutions for sheet metal fabrication. In order to make factories more competitive and eco-friendlier, the company aims to leverage their position as a solution provider while making great strides in energy efficiency.

“Our customers have seen huge increases in the cost of production due to higher energy prices. Our technologies reduce the use of energy-intensive materials and are less power-hungry overall. By offering more sustainable and lower-carbon methods of sheet metal fabrication, we can help companies fight more effectively against climate change and slash the cost of materials and manufacturing,” says Stephan Mayer, Chief Executive Officer of Machine Tools at TRUMPF. Some of TRUMPF’s solutions at EuroBLECH included the new “Eco Cooler” system that controls laser-cutting machine temperature using pure water instead of chemical refrigerants, which is more energy efficient and more environmentally friendly. It’s clear that digitalization and automation are still the driving forces of industry. TRUMPF wants to help companies optimise their processes through digitalisation.

TRUMPF continues to invest in their own digitalisation and automation efforts, with the goal of boosting overall productivity and enabling production of high-quality sheet metal parts. They’ll also help companies who want to implement these best practices themselves. With new software that was showcased at EuroBLECH, TRUMPF has taken an important step in this direction. The company will work with users to convert their traditionally manual processes into digitised information flows that are linked and communicated with different departments in a company’s value chain.

Today, one of the biggest hurdles in sheet metal production is a lack of skilled workers. TRUMPF continues to expand its share of the market with simpler and more affordable machines, and this year’s EuroBLECH customers witnessed the launch of an entry-level bending machine: TruBend 1000. “By expanding our portfolio, we’re tapping into a growing market for simpler machines.” Mayer says. The TRUMPF entry-level machines meet the same safety standards as their high-end models and provide users access to the same tried-and-tested range of TRUMPF services. They’re safe and easy to use, which means companies can take advantage of labour shortages with these affordably priced machines. Customers who purchase these new machines also have access to suitable financing packages. A one-stop shop for the most demanding applications.

At EuroBLECH this year, TRUMPF showcased a couple of novel solutions which are aimed at taking manufacturing to an even higher level. The new robot gripper for automated bending cells allows companies to switch between materials faster and carry out low-volume manufacturing. Plus, the TruLaser 5000 laser-cutting machine now has double the laser power. It’s capable of cutting higher thicknesses of material and increases productivity by up to 80 percent; much more than before.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

Press Brake machines for sale in Australia and New Zealand from TRUMPF. Machines for die and panel bending as well as large format bending.

Fiber laser cutting machines for sale in Australia and New Zealand. Premium TRUMPF and entry level JFY machines available.