The plastics manufacturing sector in Australia and New Zealand is evolving rapidly, driven by the growing demand for sustainable solutions, energy efficiency, and cost-effective production methods. Companies across key industries—such as packaging, automotive, medical, and consumer goods—are adopting advanced technologies to reduce their environmental footprint while maintaining high productivity and profitability. Innovation in injection moulding technology stands out as a critical enabler of sustainable manufacturing.

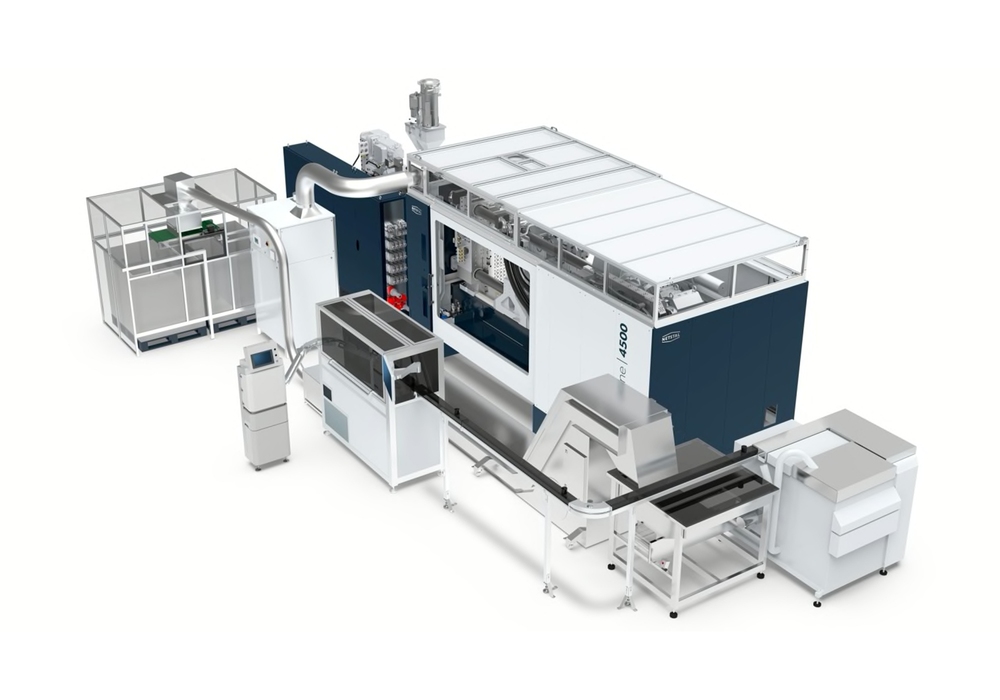

Netstal’s CAP-Line system has transformed the plastics manufacturer by offering a game-changing solution that combines energy efficiency, operational excellence, and environmental sustainability. We explore how the CAP-Line system is helping plastics manufacturers in Australia and New Zealand achieve their sustainability goals while enhancing profitability.

Challenge: Balancing sustainability and profitability in plastics manufacturing

Plastics manufacturers in Australia and New Zealand face significant challenges:

- Rising energy costs: Traditional injection moulding systems consume excessive energy, leading to high operational expenses.

- Environmental regulations: Increasing pressure to reduce carbon emissions and comply with stringent sustainability standards.

- Production demands: The need to maintain high production output without compromising product quality or efficiency.

- Competitive market: Staying competitive in a dynamic industry while addressing sustainability and cost-efficiency.

These challenges highlight the urgent need for innovative solutions that can deliver energy savings, cost reductions, and environmental benefits without sacrificing performance.

Solution: Netstal’s CAP-Line system with adaptive system pressure reduction

Netstal’s CAP-Line system addresses these challenges through its adaptive system pressure reduction technology. By intelligently adjusting system pressure to match operational requirements, the CAP-Line system significantly reduces energy consumption while maintaining production stability and product quality.

Key features of the CAP-Line system:

- Adaptive system pressure reduction: Automatically adjusts pressure to an optimized level of 170 bar (compared to the standard 250 bar), ensuring energy is used only when necessary.

- Kinetic energy recuperation: Recovers and reuses energy during machine operation, further enhancing efficiency.

- Seamless integration: A retrofittable option allows manufacturers to upgrade existing systems without major disruptions.

Benefits of the CAP-Line system:

- 6% reduction in energy consumption: Active system pressure reduction ensures only the required hydraulic energy is used.

- Improved economic efficiency: Lower energy consumption translates to significant cost savings over time.

- Sustainable production: Reduced electricity usage leads to a smaller CO2 footprint, aligning with environmental goals.

- Consistent performance: Maintains production stability and reliability despite reduced system pressure.

Implementation: Seamless integration and rapid ROI

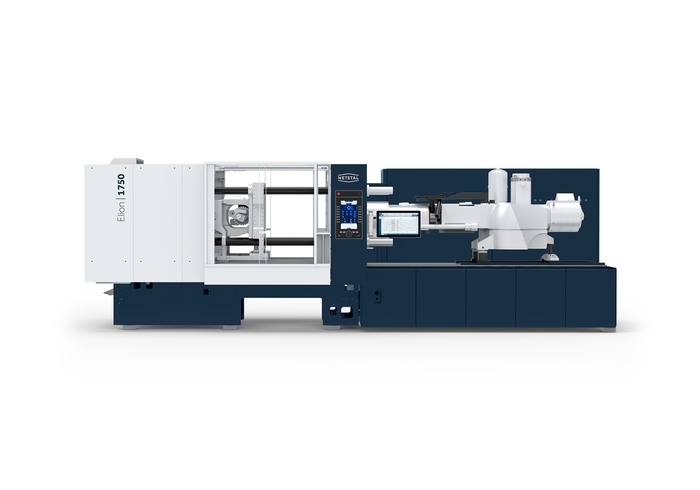

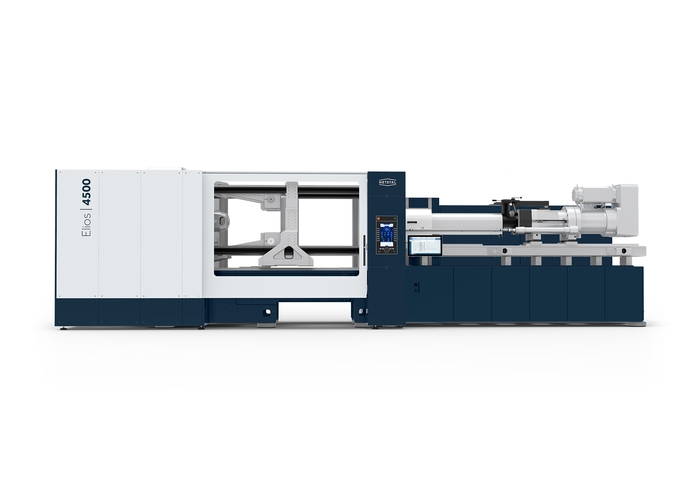

Netstal conducted extensive testing to validate the effectiveness of the CAP-Line system. The adaptive system pressure reduction technology was integrated into the ELION and ELIOS series machines, enabling real-time adjustments to optimise energy output.

Implementation highlights:

- Real-time optimisation: The system continuously monitors and adjusts pressure to avoid unnecessary energy consumption.

- Cost-effective upgrade: The retrofittable option ensures quick integration into existing processes, minimising downtime.

- Rapid amortisation: Manufacturers experience immediate reductions in operating costs, leading to a fast return on investment.

Results: Driving sustainability and profitability in Australia and New Zealand

The adoption of Netstal’s CAP-Line system will deliver transformative results for plastics manufacturers in Australia and New Zealand:

- Energy efficiency: Significant reductions in energy consumption contribute to lower operational costs.

- Cost savings: Improved economic efficiency enhances long-term profitability.

- Environmental impact: Reduced CO2 emissions support sustainability initiatives and regulatory compliance.

- Competitive advantage: Manufacturers gain a competitive edge by offering high-quality, sustainably produced plastic components.

Conclusion: Setting a new standard for sustainable manufacturing

Netstal’s CAP-Line system is redefining the future of plastics manufacturing in Australia and New Zealand. By combining energy efficiency, cost savings, and environmental sustainability, this innovative technology empowers manufacturers to meet the demands of a rapidly evolving industry.

For businesses seeking to reduce their carbon footprint, lower operational costs, and maintain a competitive edge, the CAP-Line system represents a proven solution that delivers both economic and environmental benefits. As the plastics industry continues to prioritise sustainability, Netstal’s advanced injection moulding technology is setting a new standard for high-performance, sustainable manufacturing.

How can my business benefit from energy-efficient solutions like the CAP-Line system in my manufacturing process?

Contact a Headland Plastics expert to learn how the Netstal CAP-Line system can transform your operations, reduce energy costs, and support your sustainability goals. Whether you need guidance on system integration, cost analysis, or sustainability benefits, our team can provide tailored solutions to meet your specific needs.