As the plastics industry in Australia and New Zealand accelerates its transition toward a circular economy, the need for smarter, more sustainable manufacturing practices has never been greater. With increasing pressure to reduce waste, lower emissions, and improve resource efficiency, manufacturers are seeking solutions that enable them to deliver high-performance products with minimal environmental impact. At the forefront of this transformation is KraussMaffei, a global technology leader in injection moulding and advanced recycling systems, redefining what’s possible in plastics production.

Transforming circular economy goals into manufacturing reality

The shift to a circular economy is not simply about recycling more—it’s about redefining how products are made. This requires precision machinery capable of processing recycled materials at scale while maintaining the quality, strength, and performance standards demanded by industries such as medical, packaging, and automotive.

KraussMaffei’s injection moulding machines are built for this challenge. Designed for high-performance, high-efficiency operations, they enable manufacturers to incorporate recyclates and alternative materials without compromising on consistency or reliability. By combining injection moulding expertise with industry-leading recycling technologies, KraussMaffei empowers manufacturers to close the loop—turning waste into resource and enabling sustainable growth.

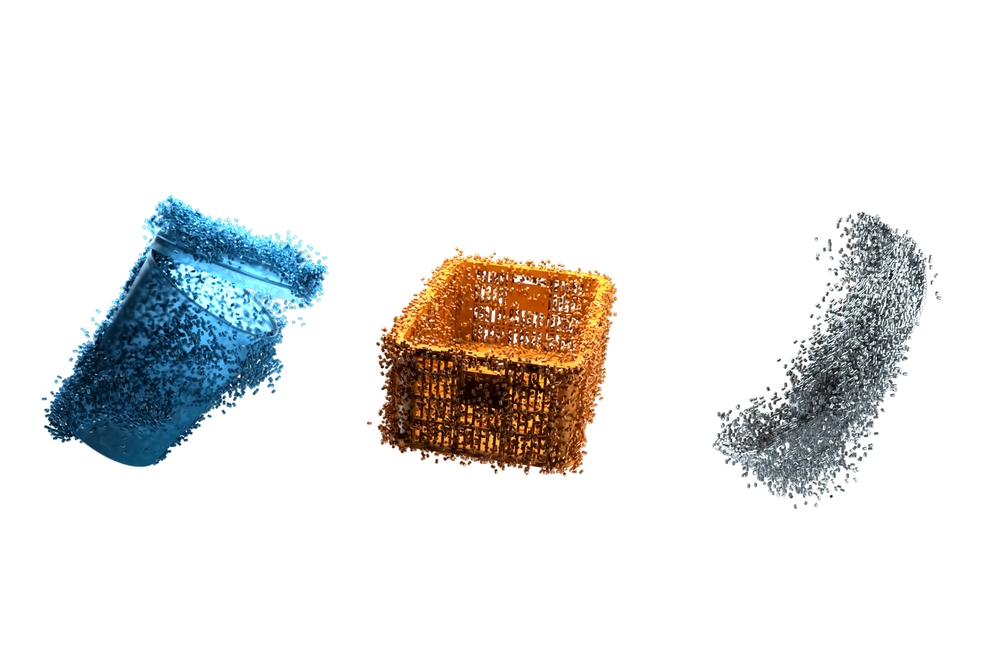

Unmatched expertise in recyclate processing

What sets KraussMaffei apart is its leadership in advanced recycling systems, delivering regrind material of near-virgin quality. Their technology effectively removes contaminants, adds stabilisers, and remelts a broad range of recovered plastic and waste to create recycled materials with mechanical and sensory properties nearly identical to new polymer.

This capability offers real-world value:

- Significant cost savings through material reuse

- Reduced energy consumption and CO₂ emissions

- Confidence to use recycled content in high-performance applications

In polyurethane (PU) recycling, KraussMaffei also leads with mechanical recycling solutions that repurpose PU waste into hybrid materials—cutting reliance on petrochemicals and supporting material circularity. Additionally, the company is pioneering bio-based rebonding techniques, utilising natural compounds to further minimise environmental impact in PU recycling.

These innovations are helping ANZ manufacturers integrate sustainability into their operations while preserving the high standards their markets demand.

Precision moulding meets sustainable production

KraussMaffei’s next-generation injection moulding systems are engineered for flexibility and efficiency. With servo-electric drives and adaptive process control, these machines offer:

- Up to 60% energy savings compared to hydraulic alternatives

- Faster cycle times and reduced scrap rates

- Low maintenance costs through predictive diagnostics

In fast-paced industries, consistent part quality, repeatability across complex geometries, and reliable multi-cavity moulding are essential. KraussMaffei machines meet these demands—making them ideal for high-mix, low-volume production or scalable mass manufacturing.

Empowering a circular future

As the plastics industry moves away from the concept of “single-use plastic” the ability to process and reuse recycled plastics effectively becomes a competitive advantage. This can only be achieved with the right equipment—injection moulding systems robust enough to handle recycled inputs, yet precise enough to meet stringent quality expectations.

KraussMaffei’s solutions are purpose-built to meet these needs, enabling ANZ manufacturers to lead with confidence in the circular economy.

Conclusion: Lead the change with KraussMaffei

Innovative injection moulding machines are not just responding to the needs of a changing industry—they’re actively shaping its future. With unmatched strength in precision moulding, advanced recyclate integration, and polyurethane recovery, KraussMaffei technologies are helping manufacturers turn sustainability strategies into tangible outcomes.

Is your business ready to lead the way in circular, compliant, and competitive plastics manufacturing?

Whether your goal is to reduce emissions, lower costs, expand into new markets, or align with circular economy principles, investing in future-ready equipment is the first step. Connect with our injection moulding and KraussMaffei experts and take the next step toward a cleaner, smarter, and more competitive future in plastics manufacturing.