Compact, flexible, and more efficient: TRUMPF unveiled a new solution for machine interlinking

Discover how TRUMPF is redefining sheet metal automation with a smarter, more flexible interlinked production system.

Log in to MyHeadland – your new customer portal | No access yet? Email marketing@headland.com.au

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

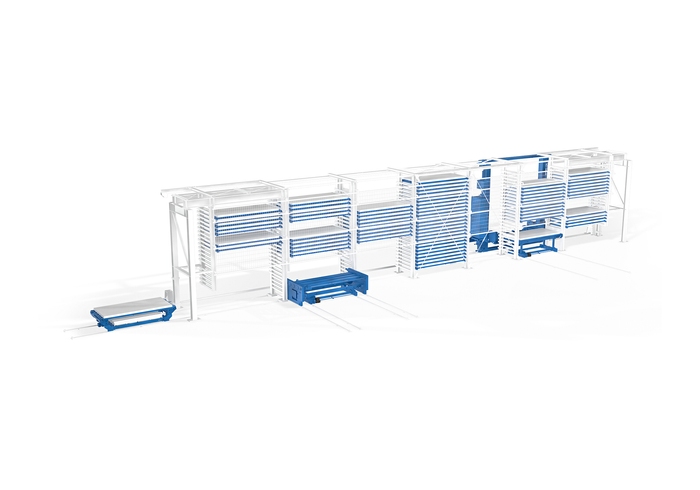

At Blechexpo 2025, TRUMPF unveiled a highly productive laser cutting, punching, and bending production system interlinked via a material buffer from STOPA. The system combined the productivity and flexibility of individual machines with the efficiency advantages of line production.

For the first time at Blechexpo, TRUMPF showcased a fully automated, interlinked system featuring the next generation of TruBend Center 7030 panel bending machines, TruMatic 5000 punching and laser machines, and the STOPA flex automated storage system. Unlike conventional interlinked production lines, this solution offered exceptional flexibility. The STOPA storage system stores parts between the individual production steps, allowing TRUMPF to combine the versatility of individual machines with the efficiency of production lines.

Stephan Mayer, CEO of TRUMPF Machine Tools, commented:

“A major step toward increasing efficiency in sheet metal production was the direct interlinking of cutting, punching, and bending even down to one-piece flow. This reduced space costs, simplified internal logistics, and minimised unnecessary parts inventories. Thanks to the integrated, fully flexible software, new parts could be programmed in no time at all.”

The networked system allowed both individual parts and high-volume series to be produced economically and efficiently. Decoupling the processes stabilised the overall system and improved the utilisation of each machine. The solution required only one operator, further reducing parts costs.

Traditional interlinked production lines operated on the “KIT” principle, where all components followed a fixed sequence of steps until the final product was reached. These rigid systems were unsuitable for small batch sizes or a high variety of variants. Interdependent cutting and bending steps often caused machines to wait for each other, reducing overall productivity.

TRUMPF adopted a different approach with its “batch production” concept. The first machine produced a set number of components, which were temporarily stored in the STOPA system before being transported to the next machine. This decoupled the production steps, enabling even small quantities down to a batch size of one to be manufactured flexibly.

Sebastian Götz, TRUMPF Product Manager, said:

“With our solution, users could freely choose their manufacturing strategy for each order. This offered efficiency advantages, for example by streamlining their logistics processes.”

The interlinked solution was managed via TRUMPF’s OSEON software, providing flexible control over material flow and full transparency across the production process. Even rush orders could be scheduled easily. The system’s medium-format machines allowed for a particularly compact footprint.

Götz added:

“Our solution gave companies the opportunity to automate production gradually and expand into a smart factory. It was particularly suited to small and medium-sized companies looking to increase capacity. Thanks to its flexibility, the system targeted product shops in elevator construction, refrigeration and air conditioning, switch cabinet construction, commercial kitchens, and shopfitting.

TRUMPF introduced a new version of the TruBend Center 7030, which worked 30 percent faster than its predecessor. This performance increase was achieved through a revised handling concept and consistently parallel-controlled axes. A rotator and 2-axis manipulator handled components close to the bending line, saving time, especially for multiple bends.

The machine featured an open concept without protective fences for faster, more ergonomic loading. Integrated laser scanners ensured maximum safety, automatically switching off the machine if the operator entered the secured area. The redesigned frame also allowed for a more attractive price point. The TruBend Center 7030 handled components up to three millimetres thick and three meters long.

The TruMatic 5000 punching and laser machine, part of the interlinked system, offered high productivity for cutting, punching, and forming parts. Equipped with a powerful 6 kW TRUMPF fiber laser, it could process a wide variety of parts. Automated features such as the Tool Master for tool changes and the Sheet Master for material flow between machine and warehouse enhanced efficiency.

Our sheet metal and TRUMPF experts can help you explore the right interlinking solution to boost efficiency, flexibility, and throughput in your factory.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

The TruBend Center 7030 is the industry leader in terms of productivity and adaptability when it comes to panel bending.

The STOPA Compact is an automated large-scale storage system for sheet metal which utilises the latest logistics and production strategies.