Changing manual manufacturing: Operator augmentation with InspecVision’s GAV System

Read how InspecVision’s breakthrough system doesn’t replace workers—it gives them X-ray vision and a photographic memory.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

The Water jet Cutting Machine Market has a high potential for growth in the APAC (Asia- Pacific Countries) region. The continuous development of automobiles, manufacturing and other sectors has a positive impact on the market. Product type (Robotic Water jet Cutting, 3D Water jet Cutting, Micro Water jet Cutting), Industry (Automotive, Electronics, Aerospace, Construction, Mining Industry), and Geography are the market segments.

The water jet cutting machine market is expected to experience significant growth over the forecasted period from 2022-2030. According to market research, the compound annual growth rate CAGR (Compound Annual Growth Rate) of this market is estimated to be 9.0%. This growth is driven by the increasing demand for mechanised cutting from the industrial sector, as well as the rising demand for water jet cutting machines in the medical and aerospace industries. The medical industry is expected to be a major driver of growth for the water jet cutting machine market. The precision and accuracy of water jet cutting machines make them ideal for cutting medical implants and other medical equipment. Additionally, the aerospace industry is expected to be a major consumer of water jet cutting machines due to their ability to cut complex shapes with high precision. The industrial sector is also expected to be a major consumer of water jet cutting machines. This is due to the increasing demand for precision cutting technology in manufacturing and fabrication. Water jet cutting machines can cut through a variety of materials, including metals, plastics, composites, and even glass. This makes them ideal for automotive production as well as for aerospace manufacturing.

The global water jet cutting machine market is a rapidly growing industry, driven by the increasing demand for precision cutting and the need for efficient and cost-effective production processes. However, there are several restraints and challenges that the industry faces. One that comes to mind is the lack of skilled individuals, including technicians, engineers, and specific OEM-trained personnel, which can limit how fast the market can grow over the forecast period. Additionally, the availability of commodities for this sector is another factor that could potentially limit the growth of the market. Another challenge for the global water jet cutting machine market is the lack of awareness about the technology. While the technology has been around for decades, it is not yet widely adopted in many industries. This is due to the fact that many people are not aware of the benefits of water jet cutting, such as its accuracy and efficiency.

A water jet is a cutting instrument that uses high-pressure water and abrasives to cut diverse sets of materials including foam, wood, titanium, granite, etc. Water jet can be used with or without an abrasive mixture. The abrasive water jet is typically used for high-strength materials such as titanium, granite, and more. The global waterjet cutting machine market is segmented based on pump type, application, pressure range, and end-use industry. The pump type is divided into direct drive pumps and intensifier pumps, while the application is divided into one, two, and three-dimensional cutting applications. The pressure range is divided into up to 4200 bar and more than 4200 bar. End-use industries include metal fabrication, automotive, ceramics, electronics, paper, and others. Furthermore, on basis of the end-use industry, the market is divided into metal fabrication, automotive, ceramics, electronics, paper, and others.

The introduction of advanced technologies such as multi-axis water jet cutting and 3D cutting has the potential to ease the water jet cutting process and increase its penetration worldwide. Moreover, newer innovations such as micro water jet cutting and nano jet cutting are expected to further supplement the growth of the water jet cutting machine market. In order to cater to the needs of a wider customer base, market players have developed water jet cutting machines at a lower price point. This combination of advanced technology and affordability has the potential to drive the water jet cutting machine market forward and increase its reach to a larger number of customers.

Headland Technology has been selling and maintaining the class-leading OMAX abrasive water jet machining systems for 14 years, we are constantly investing in improving sales and service resources to continue to provide industry-leading support. We understand the importance of having reliable and efficient machining systems, and we are here to help you find the perfect system to meet your needs. Whether you are experienced in water jet operation or new to the technology and curious if it could suit your application, contact our OMAX water jet experts and find out how Headland Technology can help you.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

The OMAX product line brings the fastest cutting speeds and highest precision compared to any other water jet in the industry.

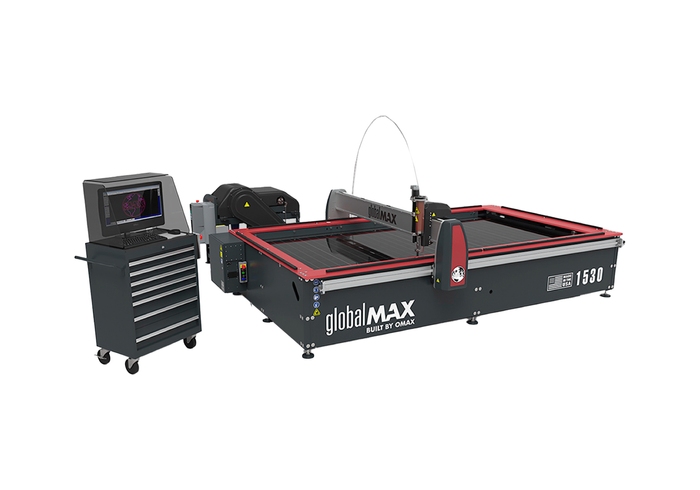

Cost efficient, high-performance water jet cutting machines. The OMAX GlobalMAX range is built to last, as well as being easy to use and ready to handle your production needs.

This range of abrasive water jet cutting machines can cut virtually any material of any thickness quickly and efficiently, maximising production and profitability.

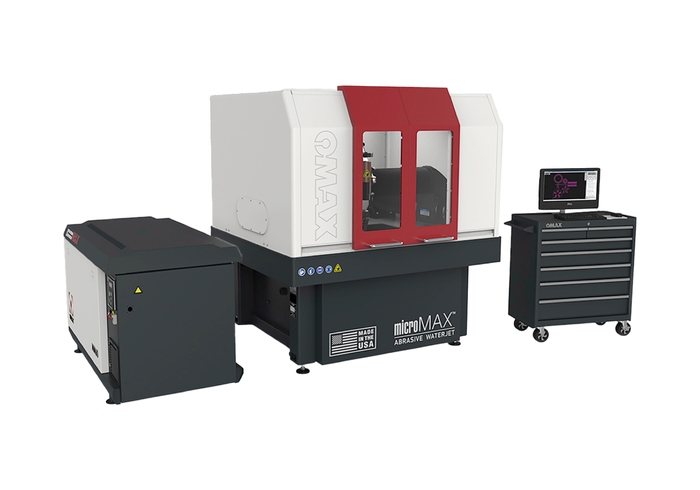

This water jet cutting machine uses advanced high precision linear encoders, innovative vibration isolation, and proven software control systems for the highest quality results.

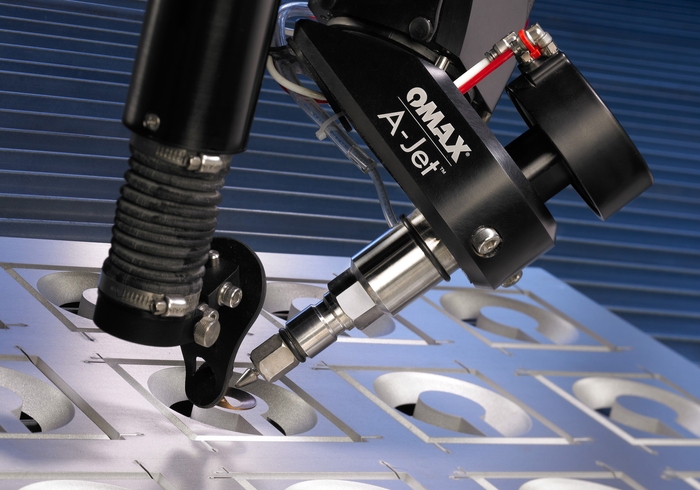

The OMAX OptiMAX is the culmination of three decades of engineering expertise and experience, resulting in the world’s most accurate water jet cutting machine.

Water jet cutting machines for sale in Australia. Our water jets can cut steel, stone, glass, rubber, plastic & more.

This advanced waterjet software coupled with 30,000 psi pump pressure drives the most efficient waterjet cutting tool for its size.