Compact, flexible, and more efficient: TRUMPF unveiled a new solution for machine interlinking

Discover how TRUMPF is redefining sheet metal automation with a smarter, more flexible interlinked production system.

Log in to MyHeadland – your new customer portal | No access yet? Email marketing@headland.com.au

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

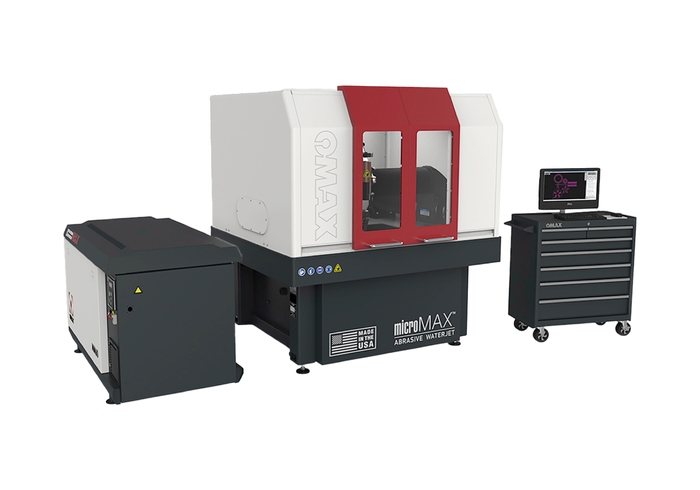

OMAX’ high performance water jet cutting machines provide speed, precision and accuracy. Their high pressure water jet cutters are capable of cutting a wide range of materials such as composites, metals, stainless steel, aluminium, titanium, copper, brass, glass, stone, concrete, ceramics, foam and rubber.

OMAX waterjet cutting machines employ high-efficiency crankshaft-driven direct-drive pumps. Faster cutting is achieved by the direct-drive pump’s ability to deliver higher pressure power to the cutting nozzle than a conventional hydraulic intensifier pump.

With these waterjet cutters there is no possibility of messy hydraulic leaks as well as a quiet operation mode. A direct-drive pump is also easy to understand, troubleshoot, and maintain. The OMAX EnduroMAX water jet cutting pump offers the highest level of dependable low-cost operation with a preventative maintenance interval of 1000 hours.

The OMAX OptiMAX is the culmination of three decades of engineering expertise and experience, resulting in the world’s most accurate water jet cutting machine.

The OMAX product line brings the fastest cutting speeds and highest precision compared to any other water jet in the industry.

This water jet cutting machine uses advanced high precision linear encoders, innovative vibration isolation, and proven software control systems for the highest quality results.

This range of abrasive water jet cutting machines can cut virtually any material of any thickness quickly and efficiently, maximising production and profitability.

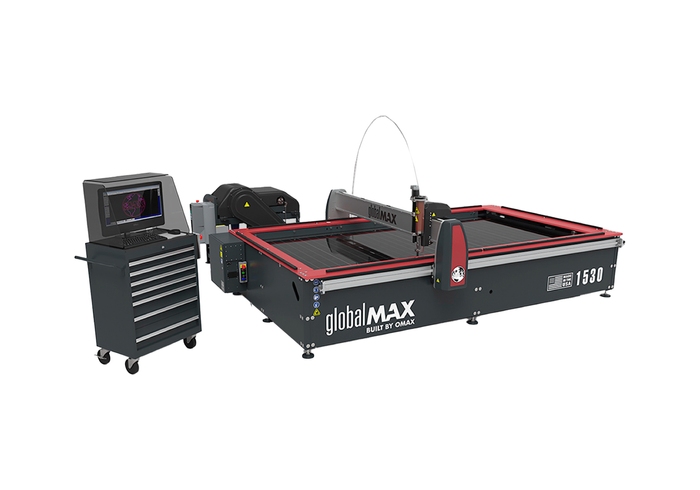

Cost efficient, high-performance water jet cutting machines. The OMAX GlobalMAX range is built to last, as well as being easy to use and ready to handle your production needs.

This advanced waterjet software coupled with 30,000 psi pump pressure drives the most efficient waterjet cutting tool for its size.

Simply put, waterjet cutting is an accelerated erosion process applied to the material of your choice. Water under extreme pressure is shot into a mixing chamber via a ruby or diamond nozzle.

When a vacuum is created by this pressure, garnet sand is drawn by the waterjet cutting machine into the stream and fired at the target to be cut. Sand particles eat away at the material, causing erosion to occur so quickly that it is considered to be cutting.

Waterjet cutting machines are a highly flexible and effective machining technique utilised across a wide variety of industries.

Water jet cutting machines have several benefits over conventional cutting methods such as lasers, plasma and saws.

Waterjet cutting produces superior edge quality, as they produce smooth, burr-free cuts due to the high speed and pressure they produce.

This means there is less need for secondary finishing, saving manufacturers time, money and improving efficiency on your production line.

Headland recently caught up with Mathew Galea from MJG Stone to learn how they’ve leveraged water jet cutting technology to help them safely and quickly manufacture their premium stone products.

Read how the integration of OMAX water jets can transform aerospace operations by improving precision, reducing turnaround times, and eliminating heat-induced material warping.

Deakin University, one of our long-standing partners in the education space, have seen tremendous value from OMAX Waterjet systems to assist students with their projects and create an educational experience more in line with industry best practices.

We can help find the perfect water jet cutting machine for your factory’s needs. Please fill out the form and one of our water jet cutting machine specialists will get in touch with you soon.

In addition to supplying you industry-leading manufacturing equipment, we provide machine servicing, software support and smart manufacturing consulting for all our brands.