KraussMaffei boosts Mexico’s agricultural industry with sustainable logistics solutions in packaging

Discover how KraussMaffei helped transform eco-friendly packaging in Mexico’s logistics sector—read the full case study now.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

The TruPrint 1000 3D metal printer is a game-changer for the dental industry, boasting unparalleled speed and quality. The dual-laser version is eight times faster than traditional milling processes. As Reinhard Sroka, a metal 3D printing expert at TRUMPF, explained in the past, 3D printing is the ideal manufacturing method for the dental industry. Dental prostheses are always custom-made, and our 3D printers can produce large quantities of them quickly and efficiently. With TRUMPF’s market leadership in Europe, including France, Italy, and Spain, the TruPrint 1000 is poised to revolutionise the dental industry.

The TruPrint 1000 is highly superior to traditional methods for producing metallic dentures, especially in its preform version. A preform is a standardised substructure that is conventionally manufactured and used as a base for printing an individual mould made of chrome-cobalt alloy or titanium. This enables the creation of abutments that support dental crowns. TRUMPF is the only company offering this technology and according to Sroka, 3D printing will eventually replace conventional manufacturing in the dental industry.

The TruPrint 1000 is the perfect solution for dental labs seeking a compact and efficient 3D printer. With its slim design, the machine can be easily transported and set up through any door, taking up minimal space. In small labs, multiple units can be used in parallel, allowing for increased production speed. The automatic plate changing system allows for up to four changes, enabling the production of metal dentures overnight.

Thanks to its compact design, the TruPrint 1000 is ideally suited for dental labs. At just around 80 centimetres wide, the machine takes up very little space, making it easy to deliver and set up through the door. Users can also have several units producing side by side in parallel in small laboratories and speed up their production even further. The construction plates on which the dental prosthesis is created change automatically up to four times. This makes it possible to produce metal dentures overnight.

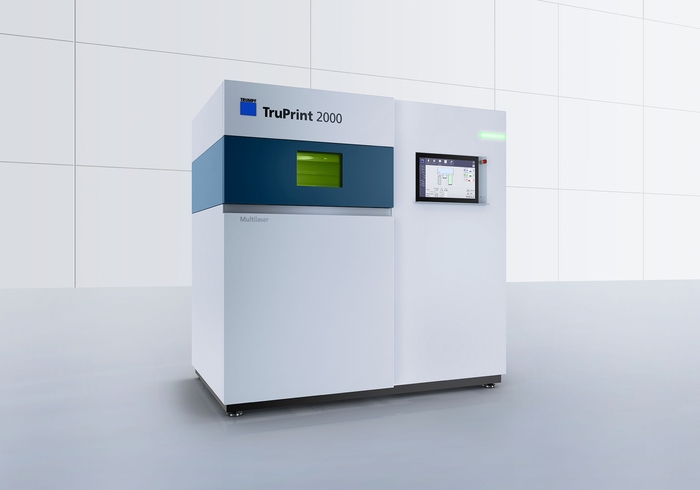

The TruPrint 2000 is a one-size-larger model, specifically designed for mass production of removable partial dentures (RPDs). These RPDs are individual dentures that can be inserted and removed independently by the patient. An optimised process allows for the printer to print up to one hundred RPDs per 24 hours, resulting in significantly reduced manufacturing costs. According to Sroka, this is important as dental laboratories need to be able to sell these RPDs at a competitive price. The laser has a small beam diameter (55 µm) which guarantees very precise surface quality and a smooth surface, resulting in a reduction in manual finishing time for dental labs.

Discover the game-changing potential of 3D metal printing technology at the upcoming TRUMPF 3D Printing in Dental Labs seminar in Singapore on April 18th, 2024. This exclusive event will provide you with invaluable insights into the latest advancements in highly productive 3D metal printers that address the cost, quality, and productivity challenges facing dental laboratories today. Industry experts will delve into the transformative impact of 3D metal printing on dental technology, showcasing the cutting-edge TruPrint 1000 and TruPrint 2000 – the most productive 3D printers for metal dental components to date.

Register now to attend the TRUMPF 3D Printing in Dental Labs seminar and hear directly from dental experts about metal additive manufacturing. Contact our Headland Technology specialists today or register here for details: Register here

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

The brand new TruPrint 1000 is not only ideal for the dental market but also impressive in the R&D area or in small series production due to the high level of robustness and quality in 3D printing.

The TruPrint 2000 provides a high-quality printing result which impresses with its surface quality and level of detail.