KraussMaffei boosts Mexico’s agricultural industry with sustainable logistics solutions in packaging

Discover how KraussMaffei helped transform eco-friendly packaging in Mexico’s logistics sector—read the full case study now.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

In the fast-paced and ever-evolving field of medical technology, precision and innovation are paramount. The production of medical devices demands the highest level of accuracy, quality, and safety, and this is where advanced manufacturing techniques come into play. One such technique that has garnered significant attention is laser welding and cutting, and a leading name in this domain is TRUMPF.

TRUMPF, a global high-tech company, has been at the forefront of developing laser cutting-edge solutions for industrial applications since its founding in 1923. With a focus on innovation and quality, TRUMPF has made substantial contributions to various industries, including automotive, aerospace, electronics, and medical technology. In the medical sector, TRUMPF’s laser welding and cutting technologies have proven to be a game-changer, especially in the manufacturing of surgical instruments.

Traditional manufacturing methods for medical instruments often involve complex procedures that can compromise the integrity of the instruments. Welding, a critical step in the production of these instruments, requires extreme precision to ensure a seamless and durable joint. TRUMPF’s laser welding technology offers a solution to this challenge.

Laser welding involves using a high-intensity laser beam to fuse metals together. This process offers several advantages over conventional welding techniques. Firstly, the heat-affected zone is minimised, reducing the risk of material distortion, and weakening. This is crucial for delicate surgical instruments where structural integrity is paramount.

Secondly, the precision of laser welding is unmatched. The laser beam’s focused nature allows for pinpoint accuracy, enabling the creation of intricate and complex designs that would be difficult or impossible to achieve with traditional welding methods. This precision is especially beneficial for manufacturing fine and delicate surgery instruments.

In addition to welding, laser-cutting technology plays a pivotal role in the medical industry. Surgical instruments require sharp edges and clean cuts to ensure they perform effectively and minimise patient trauma. TRUMPF’s laser cutting systems excel in achieving this level of precision.

Laser cutting works by directing a focused laser beam onto the material, melting or vaporising it along the designated path. The non-contact nature of laser cutting results in minimal mechanical stress on the material, ensuring a clean and smooth cut. This is particularly advantageous for creating instruments with intricate geometries and tight tolerances.

The integration of TRUMPF’s laser welding and cutting technologies into the medical instrument manufacturing process brings about numerous benefits:

Enhanced precision: The pinpoint accuracy of laser welding and cutting ensures that even the most intricate designs are faithfully reproduced, guaranteeing precision instruments.

Minimised contamination: As the process is contactless, there is no risk of introducing contaminants through physical contact, contributing to the overall hygiene of the surgical instruments.

Reduced material waste: Laser technology minimises material waste, making the manufacturing process more environmentally friendly and cost-effective.

Shorter production times: Laser welding and cutting are highly automated processes, reducing production time and increasing overall efficiency.

Customisation and innovation: Laser technology allows for rapid prototyping and easy adjustments to designs, promoting innovation and customisation in instrument manufacturing.

Superior quality: The clean and accurate nature of laser welding and cutting results in instruments of superior quality, ensuring patient safety and positive surgical outcomes.

TRUMPF’s laser welding and cutting technologies have revolutionised the medical device manufacturing process. As the demand for precision instruments continues to grow, these technologies will play an even more significant role in shaping the future of the medical industry. With ongoing advancements in laser technology, we can expect further innovations that will redefine the boundaries of surgical instrument design, quality, and performance. TRUMPF’s commitment to excellence positions them as a driving force in the evolution of medical technology, ensuring that patients and healthcare professionals alike can benefit from the best that modern manufacturing has to offer.

Our team of TRUMPF experts is available to assist you in finding the appropriate technology for your manufacturing needs.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

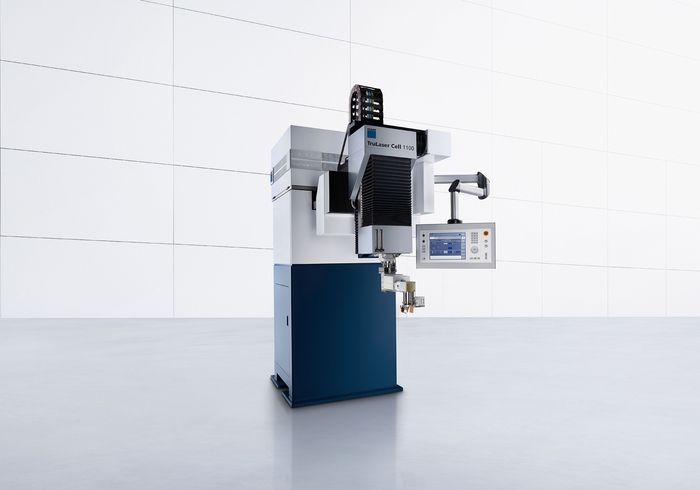

The TruLaser Cell Series 1000 is specially designed for the endless welding of any seam geometry on strips, tubes, and profiles.

The TruLaser Weld 5000 allows you to flexibly weld deep and strong seams or nicely rounded, smooth seams using one system.