KraussMaffei boosts Mexico’s agricultural industry with sustainable logistics solutions in packaging

Discover how KraussMaffei helped transform eco-friendly packaging in Mexico’s logistics sector—read the full case study now.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

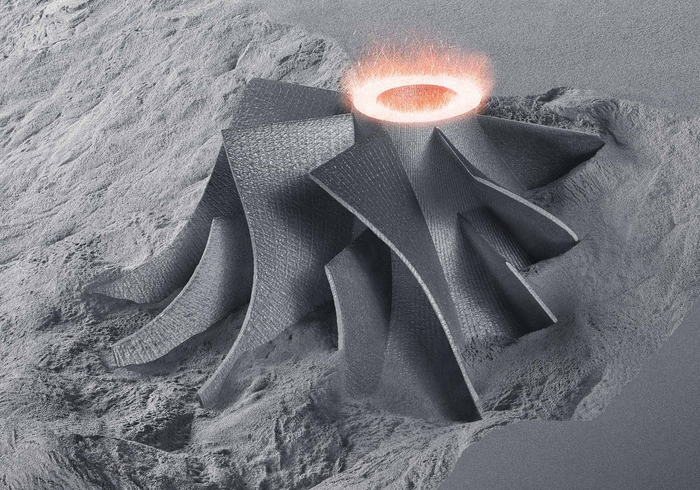

We are excited to announce that TRUMPF is exploring new application possibilities for the medical, aerospace, and automotive industries. Users benefit from a large powder and material selection, and TRUMPF works closely with powder manufacturers to make these new applications possible.

TRUMPF specialises in 3D printing systems and has expanded its selection of powder alloys for its 3D printing systems. They demonstrated the potential of new titanium, aluminium, stainless steel and tool steel alloys for additive manufacturing. Jan Christian Schauer, material expert for additive manufacturing at TRUMPF, says:

“Powder is an important component of additive manufacturing. Our goal is to provide our customers with the most comprehensive material portfolio available on the market. To accomplish this, we collaborate closely with powder manufacturers. This allows users of our equipment to utilize additive manufacturing for new applications or enhance existing applications with new powders.”

He also emphasises the importance of having a wide selection of materials to stay competitive with traditional manufacturing processes.

TRUMPF equipment has recently been upgraded to process titanium 6242, a material highly sought after by the aerospace, motorsports and energy industries. This titanium alloy is harder to process than titanium 64, the top dog, which behaves similarly to titanium 6242 at room temperature. However, at higher operating temperatures of 300 degrees Celsius and above, titanium 6242 has higher strengths. To make processing this alloy easier, the TruPrint 5000 has a 500 degrees Celsius preheating feature. This allows users to easily print components with titanium 6242, making it a viable option for many industries.

The CustAlloy aluminium alloy from ECKA Granules is particularly beneficial for the automotive industry. According to Schauer, standard aluminium has reached its limits when it comes to combining strength and elongation, and CustAlloy is the answer. This aluminium alloy has excellent mechanical properties, making it more resistant to breaking and cracking. This makes it suitable for crash-relevant applications, while also being more cost-effective than other high-end aluminium alloys which use expensive alloying elements to achieve their desired properties.

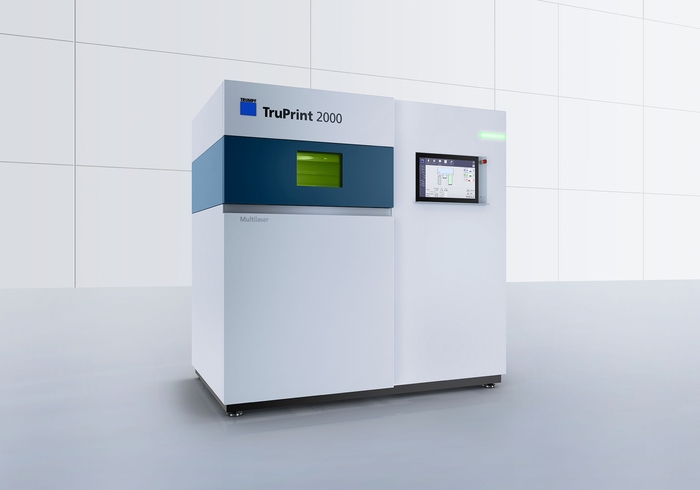

Recently, TRUMPF has qualified the Printdur HSA alloy for the TruPrint 2000, making it a particularly sustainable material due to being made from recycled scrap. This alloy has several advantages, such as being strong without the need for thermal post-treatment, and it is also less prone to rusting. The Medidur alloy, which was specifically developed by the powder manufacturer for the medical industry, has the same properties as Printdur HSA, but with higher requirements for the purity of materials. As such, Medidur consists only of pure elements. Users from the medical industry can design thin-walled and small components with this stainless-steel alloy, and it also does not contain nickel or cobalt, which are both considered potentially carcinogenic, resulting in a positive effect on the hazard load for employees who process these powders, according to Schauer.

The M789 AMPO tool steel is a versatile material that is primarily used in tool and mold making. It is easy to process without preheating the powder, making it a popular choice for users. Its high corrosion resistance makes it suitable for use with more aggressive materials, such as plastic injection molding. This makes it an ideal choice for those looking to manufacture tools that are used in combination with these materials. Its versatility and corrosion resistance make it a popular choice for many.

The Headland team is looking forward to helping you find the right solution that fits your production process.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

TRUMPF Advanced Laser Technology for sale in Australia and New Zealand | 3D metal printing, laser welding, laser marking, 3d laser cutting, and laser metal deposition

The TruPrint 2000 provides a high-quality printing result which impresses with its surface quality and level of detail.