As manufacturers across Australia and New Zealand face mounting pressure to boost productivity and cut operational costs in an increasingly competitive global market, the race toward intelligent automation has never been more urgent. Smart factory technologies and automated storage solutions have evolved to essential infrastructures for sheet metal processors seeking to optimise their production capabilities.

TRUMPF and STOPA, two industry powerhouses, joining forces to accelerate this transformation. Both companies have publicly announced to expand their strategic partnership agreement, aimed at strengthening TRUMPF’s position as a premier provider of innovative smart factory solutions. The collaboration comes at a critical juncture, as TRUMPF significantly expands its commitment to STOPA Anlagenbau GmbH, increasing its stake from 25.1 percent to 74.9 percent.

Together, they are delivering advanced automation technology purpose-built to address the unique challenges facing ANZ manufacturers striving to increase production flexibility and modernise their operations. This signals faster innovation, deeper system integration, and more unified automation solutions, backed by significant ongoing R&D to ensure these systems work seamlessly together—ultimately driving greater efficiency, reliability, and long-term value across their production environments.

Minimising unproductive time

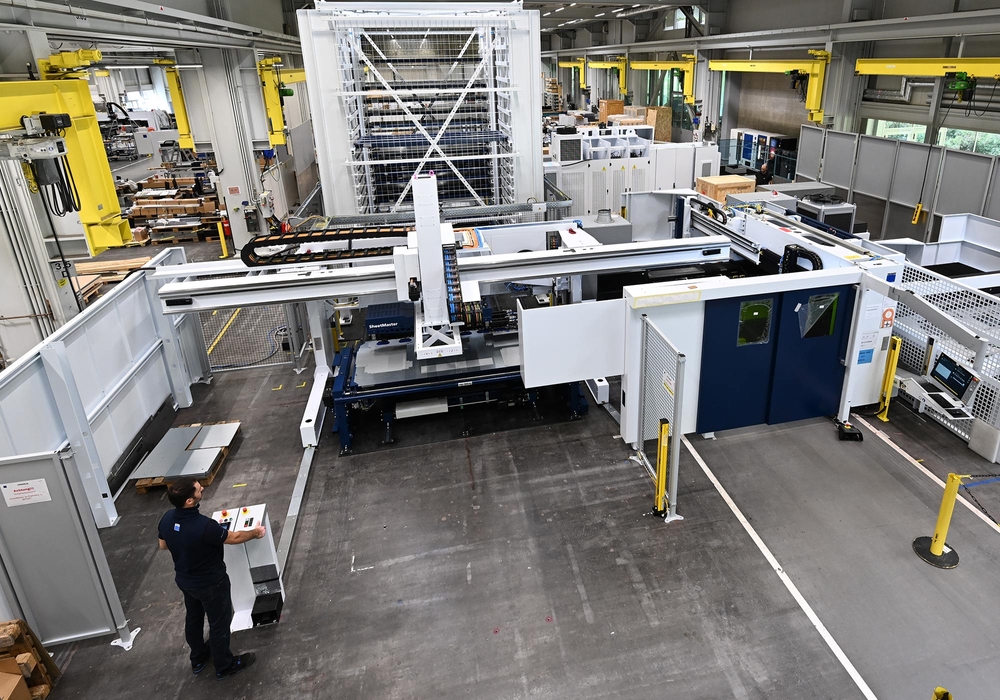

STOPA delivers automated warehousing systems for TRUMPF’s smart manufacturing solutions, amongst other applications. Users can utilise these to autonomously load and unload their equipment and connect them logistically. Manufacturing productivity rises because non-productive idle time is substantially minimised.

Till Küppers, COO TRUMPF Machine Tools:

“With this step, we want to put our long-standing cooperation with STOPA on a new footing. Our goal is to further develop smart factory solutions together and offer our customers an even broader range of efficient, sustainable, and productivity-enhancing options.”

Streamlined manufacturing planning and management

STOPA warehousing systems can be ideally configured to the expanding demands of contemporary smart manufacturing operations or incorporated into current facilities. Their specific benefits are showcased by automation combined with TRUMPF’s Oseon platform, this additionally streamlines manufacturing planning and management, extending to completely automated sheet metal fabrication.

“After almost 40 years of successful partnership with TRUMPF in production automation, we are now looking forward to taking the next step together and working even more closely in the future,” says Michael Stolzer, shareholder and managing director of STOPA Anlagenbau GmbH.

Ready to transform your manufacturing operations with Smart Factory solutions?

Australian and New Zealand manufacturers in aerospace, automotive, construction equipment, agricultural machinery, HVAC fabrication, defence, mining equipment, and general precision engineering sectors can significantly benefit from integrated TRUMPF and STOPA technologies.

These advanced automation solutions address critical industry challenges including:

- Labour shortages and rising operational costs

- Increasing demand for faster turnaround times

- Growing complexity in production requirements

- Need for sustainable and energy-efficient manufacturing processes

Contact our TRUMPF and STOPA experts to discover how smart factory automation can revolutionise your sheet metal manufacturing operations. Our experienced team understands the unique requirements of ANZ manufacturers and can design tailored solutions that deliver measurable improvements in productivity, efficiency, and profitability. Don’t let your competitors gain the automation advantage speak with our experts now about transforming your facility into a smart factory.

Image provided by TRUMPF