Precision, efficiency, and reliability are paramount in switchboard manufacturing. Switchboard and enclosure manufacturers are under constant pressure to deliver high-quality products faster and more cost-effectively. The good news? Smart factory technology is transforming the game, enabling manufacturers to streamline production, reduce waste, and increase profitability.

How Smart Factory Tech is revolutionising Switchboard & Enclosure Manufacturing

Conventional manufacturing methods often struggle to keep up with modern demands. Long lead times, labor-intensive processes, and material inefficiencies create bottlenecks. Smart factory solutions address these challenges by integrating automation, digitalisation, and advanced manufacturing technologies to enhance every aspect of production.

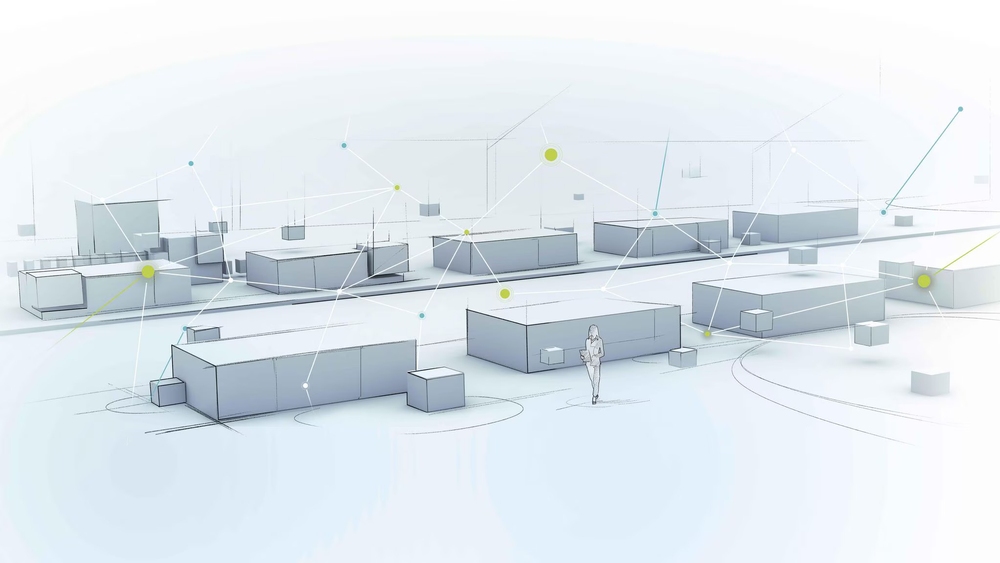

Connect all your machines

The first step towards a smart factory is having your equipment interconnected. Interconnected machines communicate seamlessly giving manufacturers full control of the manufacturing process. This leads to optimised machine utilisation, improved material management, and significant cost reduction.

The result? Profit maximisation and long-term business growth.

Key Benefits of a Smart Factory for Switchboard Manufacturers

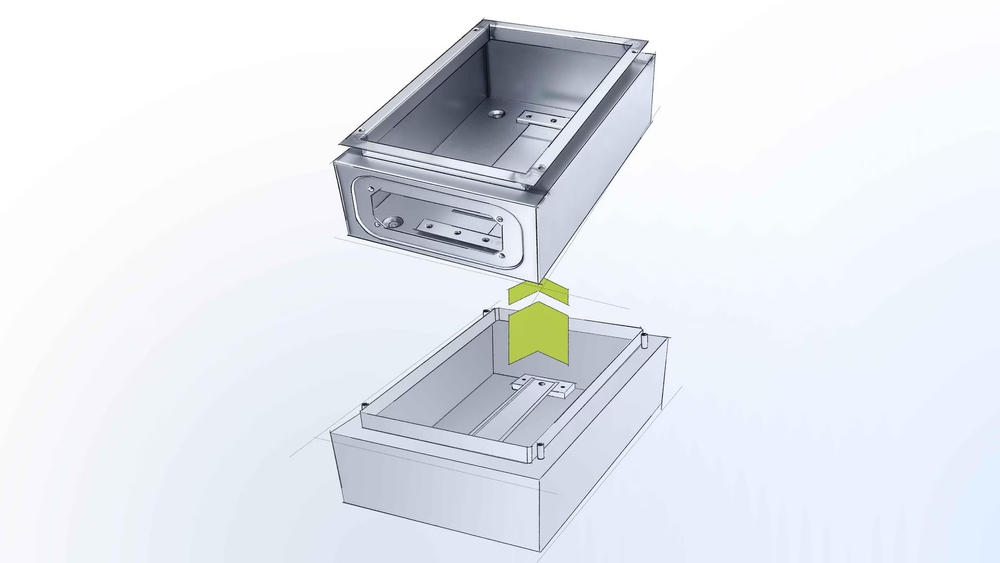

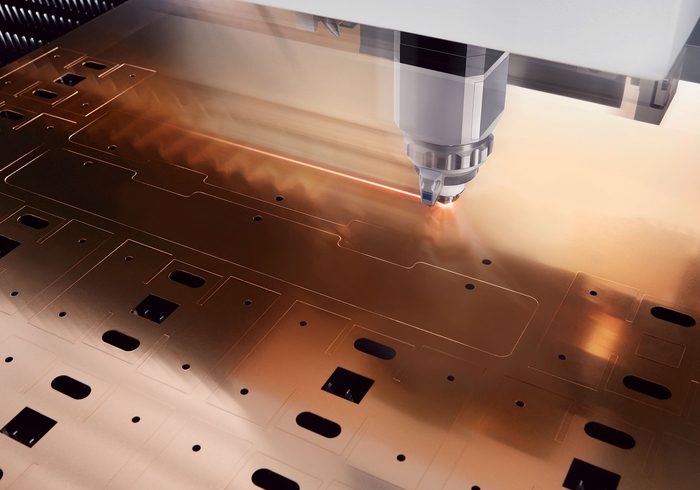

Automated Precision Cutting & Bending

TRUMPF’s high-speed laser cutting and automated bending solutions ensure that each component for your switchboard cabinets is manufactured with micron-level accuracy, reducing errors and rework.

Seamless Integration of CAD/CAM & ERP Systems

With digital connectivity, designs move from engineering to production seamlessly, minimising miscommunication and ensuring consistency across batches.

Faster Lead Times & Greater Production Flexibility

Automation enables switchboard manufacturers to handle both high-volume production and customised, small-batch orders with equal efficiency—a key advantage for enclosures and switchboards that often require tailored solutions.

Optimised Machine Utilisation

By leveraging smart automation, switchboard manufacturers can ensure that all their machines are operating at peak efficiency, reducing downtime and increasing throughput.

Material Management & Waste Reduction

TRUMPF’s smart nesting algorithms and automated material handling systems maximise sheet utilisation, reducing scrap and driving down costs.

Improved Workforce Utilisation

Rather than relying on manual processes, skilled workers can focus on high-value tasks like design, quality assurance, and process optimisation.

Cost Reduction & Profit Maximisation

Through interconnected machines, streamlined workflows, and optimised resource use, manufacturers can significantly lower production costs while boosting output and profitability.

Real-World Success Story: Kuipers Technologies

One manufacturer leading the way is Kuipers Technologies, which successfully adopted TRUMPF’s advanced laser cutting and bending solutions to revolutionise its operations. By embracing automation and smart manufacturing, Kuipers achieved:

- 30% increased efficiency through automated processes.

- Reduced manual handling, minimising errors and improving safety.

- Greater production flexibility, allowing seamless transition between high-volume and customised production runs.

Here’s how they did it

Kuipers Technologies implemented TRUMPF’s TruLaser and TruBend machines, integrating them with a Smart Factory control system that enabled seamless production flow, optimised material management, and reduced downtime.

Future-Proof Your Business with Smart Manufacturing

The shift to a smart, digitally connected production environment is no longer a luxury—it’s a necessity for manufacturers looking to stay competitive. Whether you’re a large-scale operation or a smaller manufacturer, investing in automation, connectivity, and intelligent manufacturing solutions will define your success in the coming years.

Ready to explore how smart factory solutions can transform your business? Let’s start the conversation. Reach out to our team today.