KraussMaffei boosts Mexico’s agricultural industry with sustainable logistics solutions in packaging

Discover how KraussMaffei helped transform eco-friendly packaging in Mexico’s logistics sector—read the full case study now.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

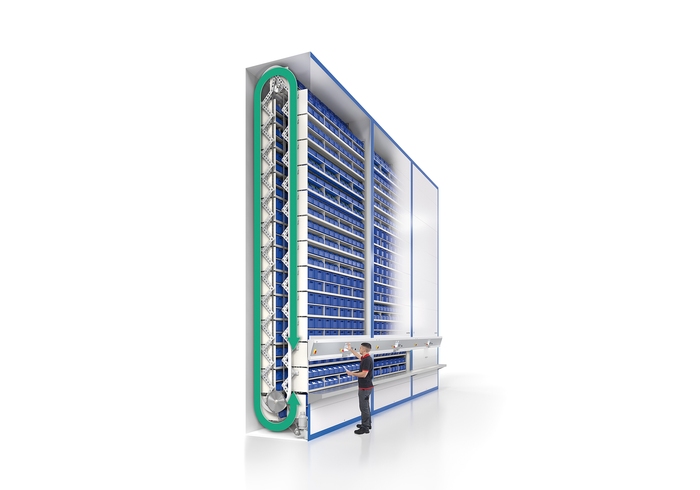

Vertical storage systems like the Hanel Rotomat can play a crucial role if you are producing, assembling, and repairing steel structures for the mining and heavy industry.

These storage solutions enable the efficient organisation of tools, spare components, and materials. They improve the movement of materials between different locations efficiently while optimising space, especially premises within confined spaces and under low ceilings.

When these vertical storage systems are combined with inventory management Hanel software you gain complete operational visibility of all inventory-related activities.

Being a supplier in the structural steel industry, particularly catering to the mining and heavy industry sectors, the significance of having easily accessible supplies, tools, spare parts, and maintenance materials cannot be understated.

The availability of these resources plays a crucial role in ensuring the smooth functioning and productivity of operations.

With the nature of work in mining and heavy industry being inherently demanding and reliant on robust infrastructure, the need for readily available supplies is paramount.

Easy access to materials that are not always easy to store, including steel beams, plates, pipes, and fittings, is essential for constructing and maintaining structures. Access to tools and spare parts is also required for equipment repair and maintenance, to minimise downtime, and maximise efficiency.

Furthermore, the availability of maintenance materials, such as lubricants, adhesives, and protective coatings, is crucial for ensuring machinery and equipment longevity and optimal performance.

To address this demand, the Hanel Rotomat storage system emerges as an exceptional solution, offering comprehensive vertical storage capabilities tailored to meet your specific requirements.

This compact vertical storage system adeptly tackles the challenges associated with storing a wide range of production components, encompassing both small parts and their bulkier, heavier counterparts.

The primary objective of Hänel’s storage systems is to maintain a constant flow of production and timely delivery of goods, thus ensuring optimal performance, superior service, and high quality. However, the capabilities of the Hänel storage systems extend beyond these benefits. They also address the storage challenges from an on-site maintenance perspective, providing a hassle-free means of keeping spare parts readily available.

Get in touch with our vertical storage experts to see how we can store your specific equipment.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

The Hänel Rotomat Industrial Storage system is a flexible and adaptable warehouse storage solution that slashes work time and administration costs.

The Hänel Rotomat Office is a vertical filing system that uses available room height in a tight office environment.