Changing manual manufacturing: Operator augmentation with InspecVision’s GAV System

Read how InspecVision’s breakthrough system doesn’t replace workers—it gives them X-ray vision and a photographic memory.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

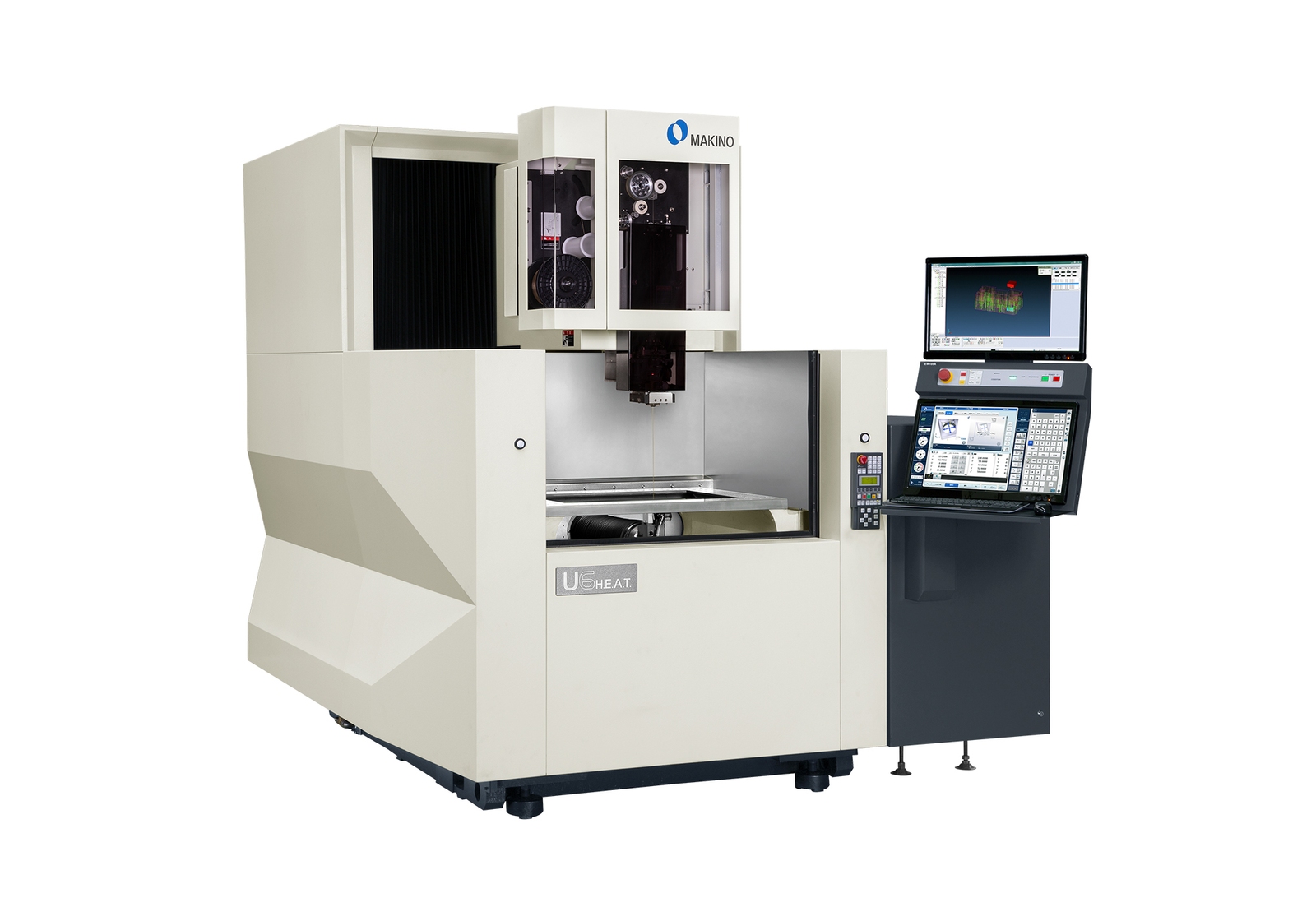

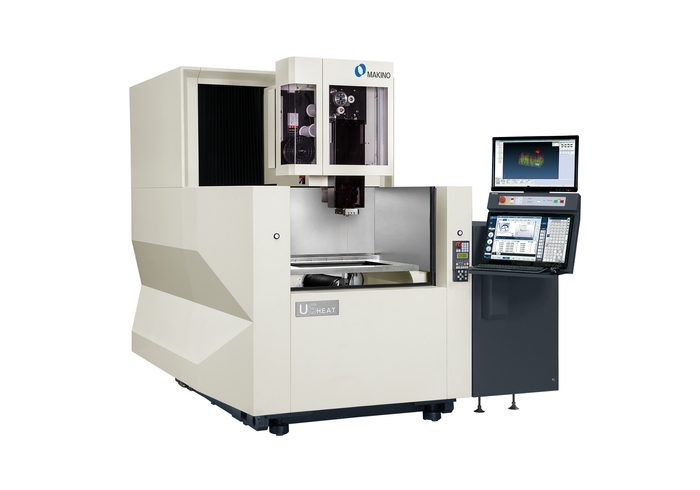

Makino’s new rust-preventive technology for water-based wire EDM machines eliminates manual cleaning time and improves part quality to maximize profit in unattended, long-run-time wire EDM processes. This new anti-rust, or “workpiece protection,” technology is environmentally friendly and eliminates the need for caustic chemicals to clean the workpiece after wire EDM machining.

This system does not impact or change anything in the EDM process, and it does not require any special cleaning or maintenance by the operator. Rust occurs on steel parts as a result of a simple chemical reaction where positive ions from the steel workpiece dissolve in the water and react with oxygen molecules to form iron oxide on the surface of the workpiece. The development of rust on workpieces has plagued EDM shops for years and has resulted in untold hours of additional time and labour to remove rust.

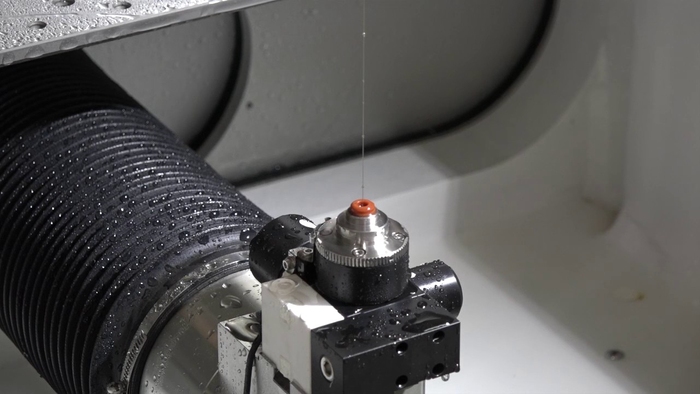

Chemical rust inhibitors that have been used as additives to the dielectric fluid often require monitoring to maintain concentration and can shorten the life of the deionising resin. Makino’s electric anti-rust unit addresses this issue by using a simple circuit to negatively charge the workpieces, preventing the oxidation process from occurring in submerged parts. The system effectively protects the entire workpiece and work-tank area, and it can eliminate post-EDM operations such as chemical cleaning, sand or glass-bead blasting, or repolishing of the workpiece.

The anti-rust system is fully integrated into the wire EDM machine and is installed on the bottom of the work tank. The system is automatically controlled by the machine and is turned on and off with the fill-and-drain button, or M-code. Any time the work tank is filled, the anti-rust circuit is activated, protecting the entire work-tank area. No additional supervision is needed on long-run-time EDM processes, providing manufacturers with dramatic improvements to their long-term efficiency and profitability.

Machines equipped with the new electric anti-rust unit have eliminated signs of rust in steel parts for up to 24 hours, even after machining has stopped. Recent tests have shown that the antirust circuit is also effective in eliminating the surface oxidation, seen as a white powder or chalk-like residue, which can form on aluminium parts. The anti-rust option can be ordered on new DUO- and U-Series wire EDMs or field-retrofitted to existing models.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

The EDAF3 machine expands upon the excellent capability and performance of the EDAF2 by offering larger X/Y/Z strokes.

Expands on the diverse capabilities of the U6 with enhancements to the flushing and filtration system

EDM machines for sale in Australia and New Zealand from Makino. Wire and Sinker EDM machines for faster part processing.