KraussMaffei boosts Mexico’s agricultural industry with sustainable logistics solutions in packaging

Discover how KraussMaffei helped transform eco-friendly packaging in Mexico’s logistics sector—read the full case study now.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

What’s the ultimate laser for your application – should I choose Fiber laser, also known as Solid State Laser (SSL), or a CO2 laser?

Answer: It depends on the type and thickness of the material you are cutting.

Why?: Due to the rate at which the material absorbs the laser. You need to choose the right laser for your application.

The absorption rate is influenced by the wavelength of the laser and also the angle of incidence.

Different types of lasers have different wavelengths, for example the fibre (SSL) laser’s wavelength is far smaller at 1 micron (on the right) than the CO2 lasers wavelength at 10 micron, shown on the left:

The angle of incidence means, the distance between point at which the laser beam hits the material (or surface), perpendicular (at 90) to the surface, so where it makes a T shape.

The angle of incidence increases (shown as a1 and a2 below) as the material increases in thickness. You can see below that with the thicker material, the orange line is at a greater angle than the blue line on the diagram below.

Fiber Laser/SSL

Highlights

CO2 Laser

Highlights

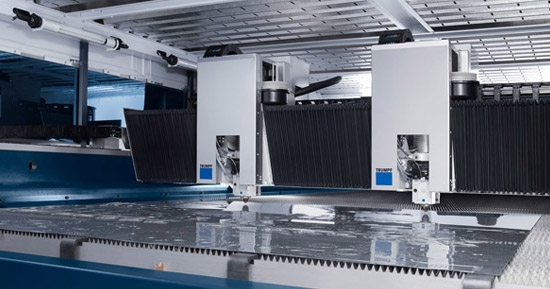

TRUMPF Presentation: Solid-state lasers in the TruLaser area – Technical considerations

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.