Changing manual manufacturing: Operator augmentation with InspecVision’s GAV System

Read how InspecVision’s breakthrough system doesn’t replace workers—it gives them X-ray vision and a photographic memory.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

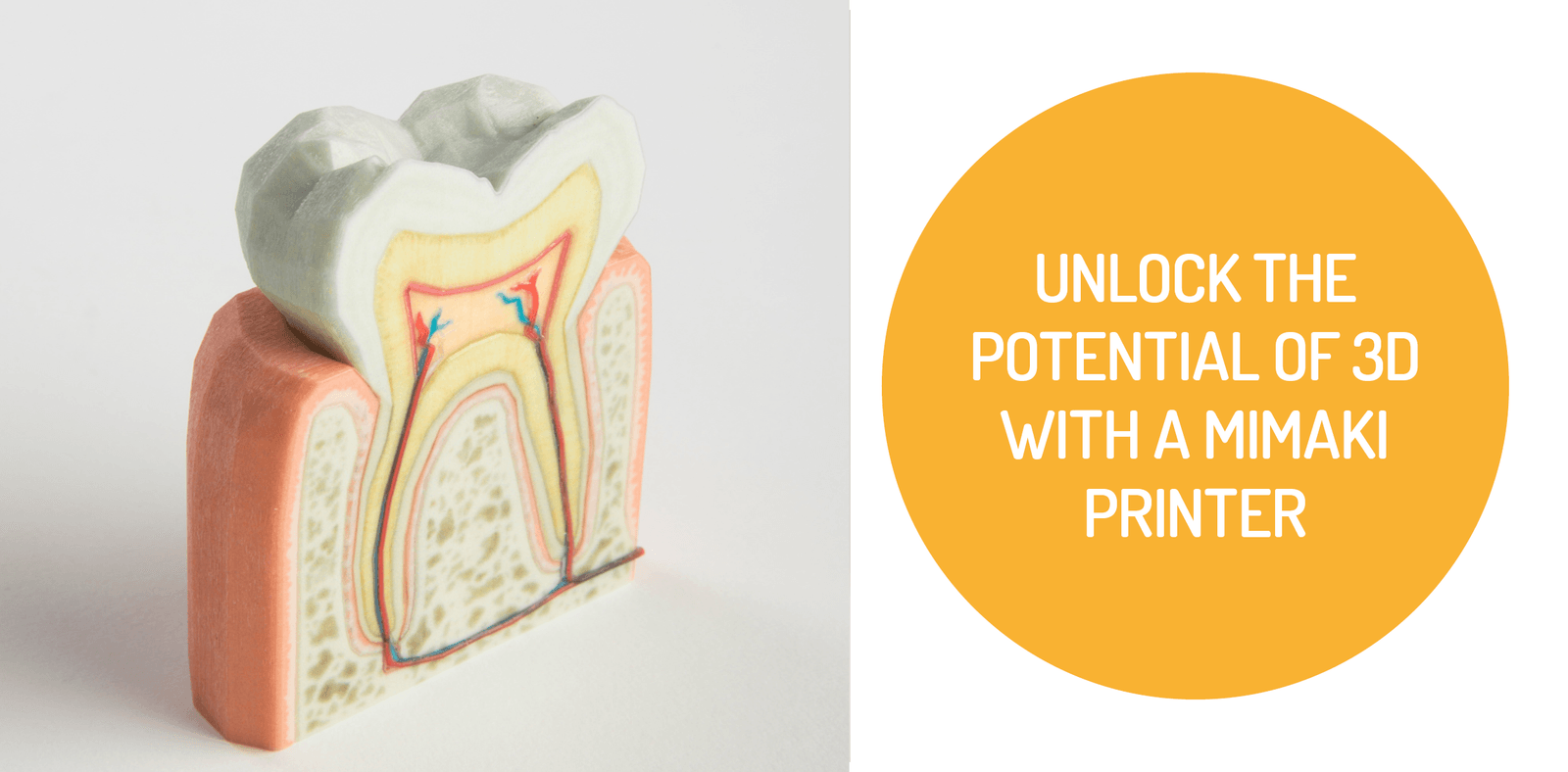

With the 3D Mimaki printer (3DUJ-553), you can create photorealistic, full-colour 3D prints. There are over 10 million colours and water-soluble support materials available. Ideal for applications where colour accuracy and fine detail are crucial. Create full-colour models and prototypes with unmatched quality.

Everything that happens after printing is easy. You can rinse products with a scrub. All you need is a bucket of water and the support material will dissolve away. Other machines use risky blasting or high chemical processing. The Mimaki ensures risk mitigation and management and significant time savings.

Use material straight out of the printer. The material is strong and does not break like plaster base materials. You can use parts straight out of the printer.

You can add texture to a product, adding leather for example, to the surface of the 3D model.

Amazing detail is possible with the 20-micron layer thickness of the Mimaki printer. Subtle colour gradients are no problem at all.

In the below video, Adam Savage shares a detailed, anatomical model 3D printed with the Mimaki. Their striking detail, fidelity, and translucent parts are remarkable.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.