Changing manual manufacturing: Operator augmentation with InspecVision’s GAV System

Read how InspecVision’s breakthrough system doesn’t replace workers—it gives them X-ray vision and a photographic memory.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

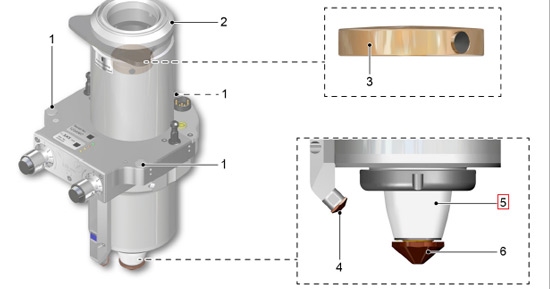

When cleaning or checking the lens in the cutting head, it is a good idea to also check the condition of the ceramic nozzle holder. The ceramic is an important part of the control line system which maintains the correct height between the nozzle and work-piece. If the ceramic is damaged it can cause inconsistent cutting quality.

You should remove the ceramic and check both the inside and outside of the ceramic for any hairline cracks or chips. If any damage is found it should be replaced, if no damage is found it can be cleaned with acetone and a cotton swab.

Please be careful when removing and installing the ceramic, Use only the tool that was provided with the machine and do not over tighten it. Take note that in only fits in one direction and be careful not to damage the electrical contact pin on the cutting head.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.