Laser technology is at the centre of many processes for manufacturing lithium-ion batteries. It is used in applications such as connecting battery cells together into modules or packs, welding battery enclosures, cleaning of terminals and foil cutting to name a few. Let’s deep dive into the manufacturing process of welding lithium-ion battery contacts and find out how recent advancements in laser technology are solving industry-wide problems.

What is a battery pack?

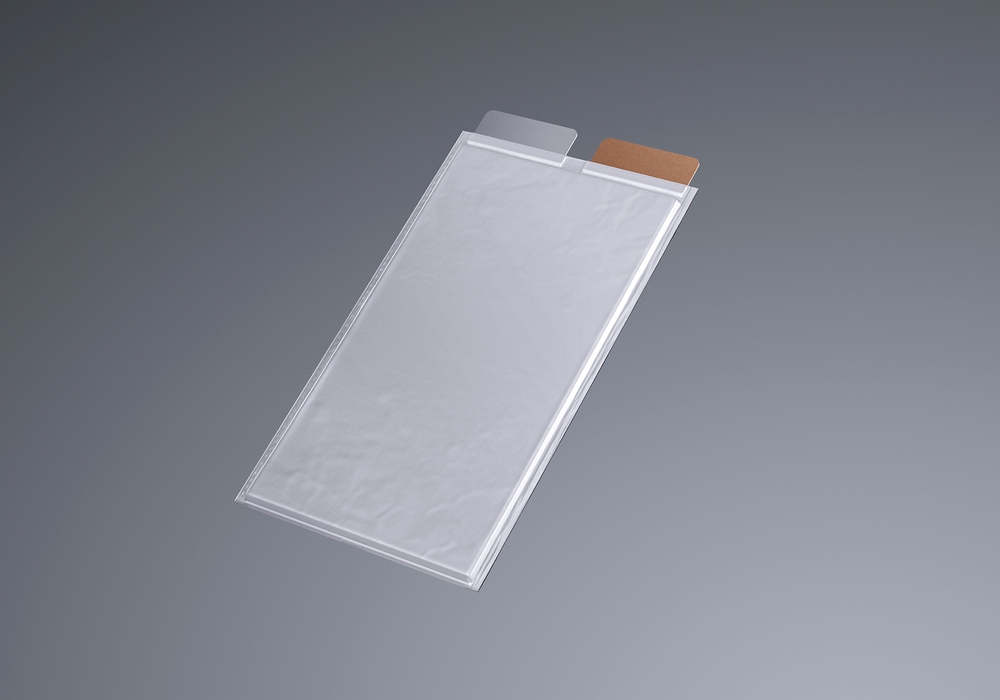

To understand the challenges of contact welding battery packs, we must first understand the anatomy of a battery cell. A battery cell refers to an individual component responsible for storing and supplying electrical energy within a battery pack. The battery cell is comprised of a positive terminal and a negative terminal. These terminals are typically located on either end of a cylindrical battery cell and are made of conductive materials.

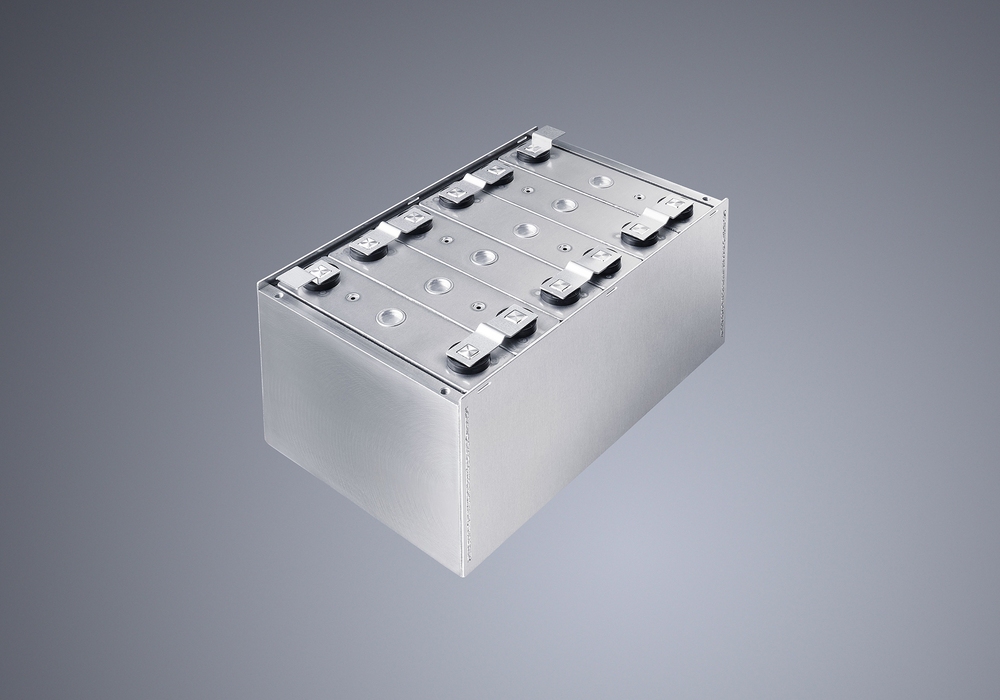

Battery packs, as the name suggests, are many individual battery cells packed into a protective, easy to manage enclosure. These battery packs can hold hundreds of individual cells in order to supply enough voltage and amperage to external components attached to them. The role of the battery pack is to conveniently connect hundreds of individual cells together and this is done in a few ways.

Battery contacts, bus bars or fused links are ways in which these battery cells are connected to one another. In general, these are conductive pieces of metal that are mechanically connected to each terminal of the cells in different configurations to either increase the overall voltage of the pack or increase the capacity of the system.

These strips of metal are usually spot welded in place using a resistance spot welding machine. This machine passes a low voltage, but very high current through the battery contact and the cell terminals. The intense heat that is produced melts the two materials together, creating a mechanical connection.

Challenges in contact welding of battery cells

Some of the main challenges associated with welding contacts to battery cells are material consistency, welding location, thermal management, weld quality and safety. We will cover these topics from the point of view of conventional resistive spot welding.

Battery cells and interconnecting contacts can vary in thickness, composition and surface finish, which can affect the quality and reliability of the welds. For this reason, material consistency is an important parameter to control. If the material is too thick this may require higher welding currents to bond correctly. Likewise, if the composition, surface finish or cleanliness of the contacts change slightly from batch to batch, this can mean the mechanical bond is compromised.

Another factor is welding location. The location of the weld on a battery cell can affect its electrical and thermal performance. Welding too close to the edge of the cell can result in damage to the battery or create a weak connection. In the case of e-mobility where the battery packs are subject to extremes in temperature, vibration and electrical load, reliability in these battery contacts are crucial.

Contact welding generates heat which can cause localized overheating of the battery cells and damage the electrolyte or other internal components. Proper thermal management is critical to prevent overheating of the cells and lasting damage.

Weld quality as we have touched on previously is extremely important. If a weld does not have a strong mechanical bond this could cause intermittent issues or in the worst case, a catastrophic failure. Lithium-Ion battery chemistry utilizes volatile, reactive metals which, if not used within its safety parameters can cause a fire or explosion. Weld quality is critical to prevent issues such as shorting battery cells, over discharge or damage to the cell packaging.

Lastly, a challenge many people do not think about is safety of the production line worker. They typically would be handling many hundreds or thousands of these batteries a day, welding these contacts on by hand one by one. Repetitive strain injuries, eye injuries from strong welding flashes and fire hazards from flying sparks are just some safety concerns that arise when welding these battery contacts using conventional resistive spot-welding techniques.

TRUMPF provided solutions for contact welding

TRUMPF is a solutions provider who has over 100 years of experience in producing machine tools for the manufacturing industry. One of their fields of expertise is in laser welding applications. Laser welding has been making waves in the manufacturing industry due to its reliability, breadth of applications, speed and cost savings due to no ongoing consumables.

To combat the challenges of conventional spot welding, TRUMPF have employed some high-tech solutions into their laser welding machines. These machines are fitted with the newest generation of laser source technologies – the disk laser, there are smart vision systems that monitor the welding process in real-time, patented fiber optics and beam shaping technology and dedicated laser application centres to test and develop new laser welding strategies.

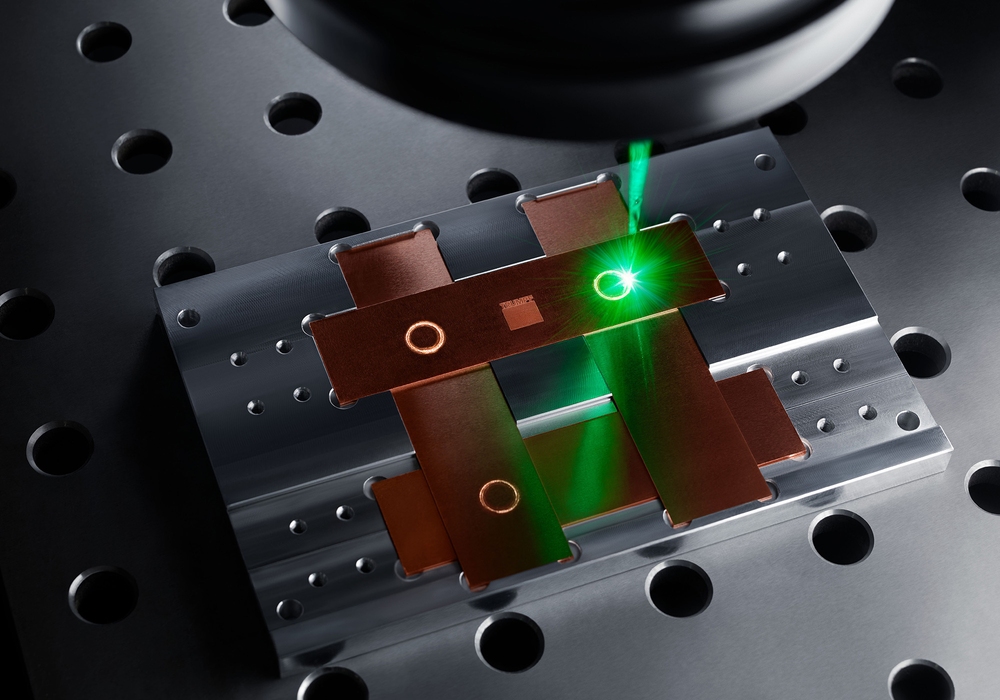

Battery manufacturing requires welding of dissimilar metals such as copper and aluminium. As you can imagine these metals have different electrical, mechanical and chemical properties. This makes it particularly difficult to reliably spot weld these materials together without a tight tolerance on all process parameters. Laser welding takes the guess work out of the equation. In particular the TRUMPF green disk laser is one of the most vital piece to this puzzle.

The green wavelength produced by the TRUMPF TruDisk laser sources are specifically designed to be absorbed by all common battery cell materials, in particular copper and aluminium. This high absorption ratio of the green wavelength means it is able to achieve a much higher quality weld bond between these materials, bond these materials independent of surface finish or oxidation and produce repeatable, consistent results.

The construction of the TruDisk laser source is also something to mention, as the laser source is totally immune to back-reflections. In most cases these back reflections would damage other laser source technologies and render them useless for some welding applications. The patented disk laser technology redirects any back reflected laser light into the laser cavity instead of its sensitive laser diodes.

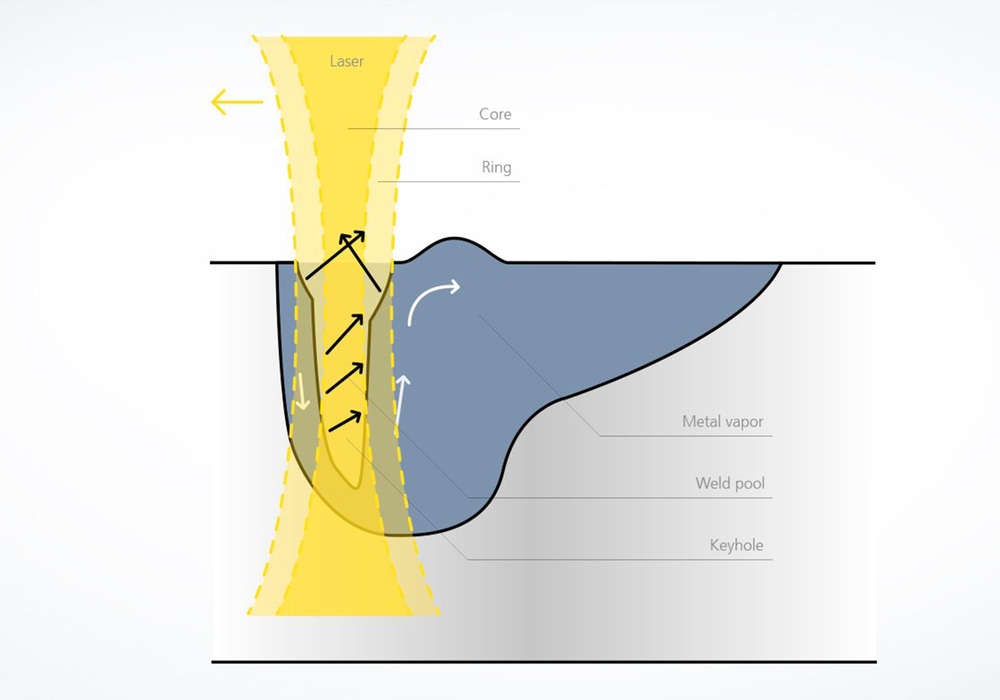

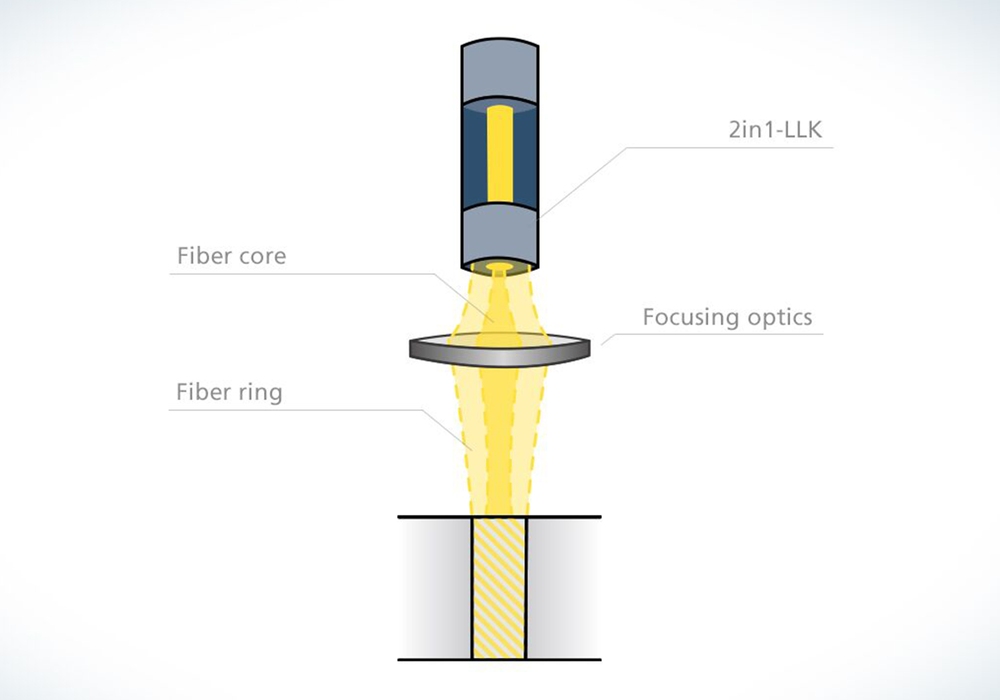

One last topic to cover on the TRUMPF laser source is the BrightLine Weld option which is unique only to TRUMPF. TRUMPF developed this dual mode fiber optic cable in order to get the best laser welding quality results in the industry. The BrightLine Weld option shapes the laser beam by directing a portion of the laser output into the inner core producing a small high intensity laser beam, and the rest of the laser power into an outer ring. This is done to control the molten pool of metal that is created when welding. This not only offers a strong reliable weld, but also practically eliminates any welding spatter.

While we are on the topic of high-tech machine options, here is something that might blow your socks off. Real-time weld monitoring, including seam tracking and weld quality verification. That’s right, the TRUMPF laser welding systems are equipped with a highly sophisticated vision system that feeds back crucial parameters into the laser source, programmable focusing optics, kinematic system and software to ensure every weld is 100% consistent. This vision system eliminates the possibility of incorrect weld positioning, overheating or other thermal issues, inconsistent or weak bonds and reliance on skilled staff.

For these reasons it is quite clear to see why TRUMPF laser welding solutions are the best fit for battery manufacturing applications. TRUMPF are not new players in the battery manufacturing game and certainly not in laser technology. However, if there is a very unique application that requires tight tolerances or strict welding requirements, there is only one way to prove their expertise, and this is done in the TRUMPF laser application centre.

TRUMPF Laser Application Centre (LAC) for application development

The TRUMPF Laser Application Centre or LAC for short is every manufacturer’s dream. The LAC is a state-of-the-art showroom featuring one of every laser technology solution TRUMPF offer. These showrooms offer live insights into the world of laser processing through laser marking, laser welding, laser metal deposition, laser cutting, and additive manufacturing.

Here you can bring your parts for testing or develop hand in hand with TRUMPF’s experts your laser welding strategies and application solutions. The TRUMPF LAC’s are located around the world with the largest two located in Germany and USA. These flagship locations are open year-round and are buzzing with hundreds of customers and industry experts, which you are more than welcome to learn from.

Headland Technology can help you solve your battery welding challenges

Our team of experts has extensive knowledge of TRUMPF products and is fully equipped to assist you in finding the optimal solution for your specific requirements. Trust us to guide you through the process and deliver the best possible outcome for your business.