Changing manual manufacturing: Operator augmentation with InspecVision’s GAV System

Read how InspecVision’s breakthrough system doesn’t replace workers—it gives them X-ray vision and a photographic memory.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

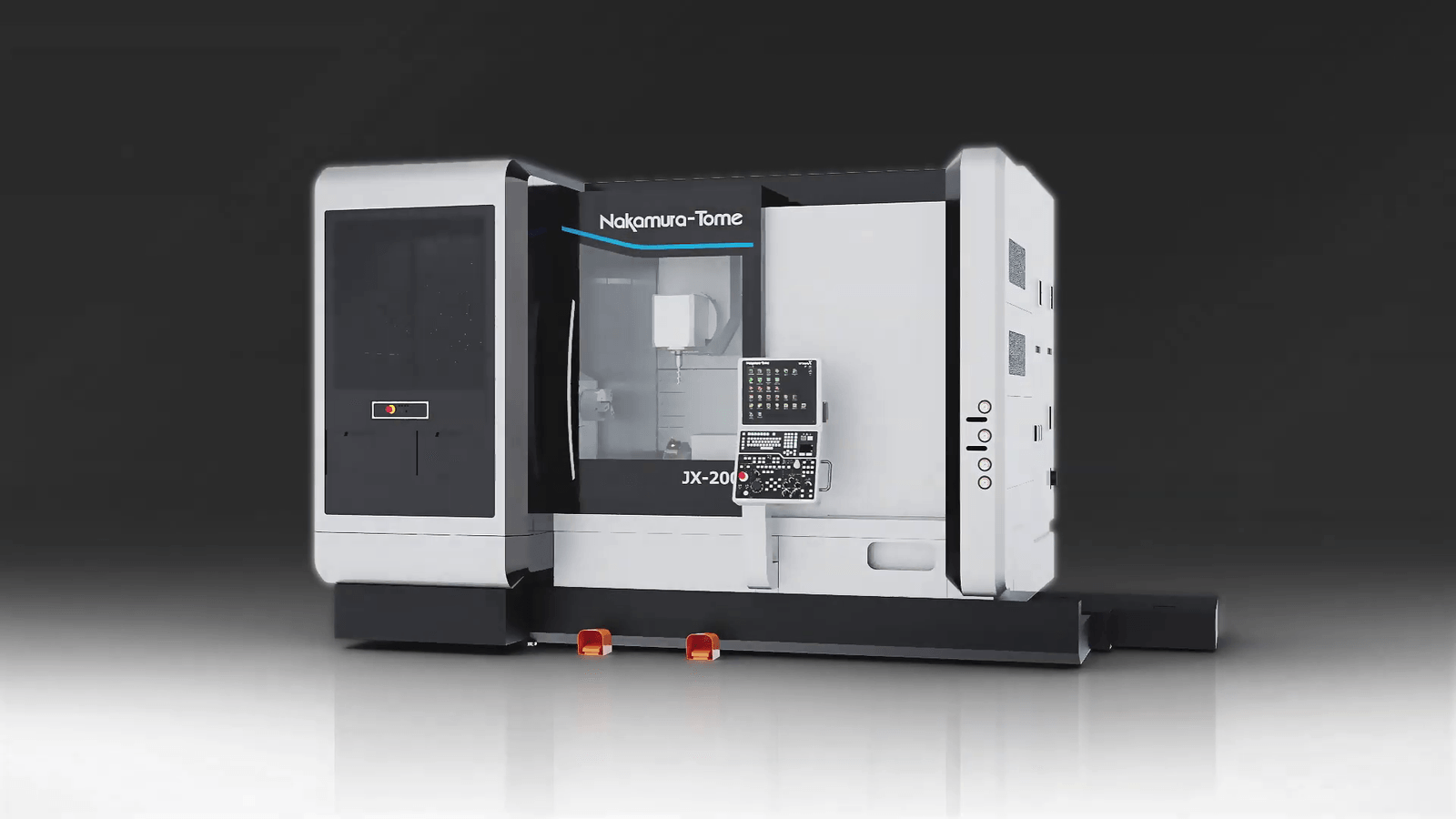

Headland is excited to announce the newest addition to our CNC product portfolio, the Nakamura Tome JX 200. The JX 200 is a revolutionary multi-tasking machine that was a response to the markets need for more flexible machining in a production or jobbing shop environment.

The JX 200 allows manufacturers to consistently create high quality products with high accuracy, regardless of material and shape. It accommodates many tools and handles multiple types of small-lot production compared to other ATC machines on the market.

Equipped with the world’s shortest tool spindle and subsequently a wider machining area, the JX 200 enables a wider range of workpiece applications. A truly all in one machine, it handles turning, milling, drilling and gear cutting.

The JX 200 also has a new column structure that optimises its centre of gravity and strengthens it against loads from any direction. It is this column structure that enables it to machine such a wide variety of materials and shapes.

Another spectacular improvement of the JX 200 is its flexible range of motion. Having a tool spindle that swivels from -95 to +95 degrees makes the machine applicable to almost any workpiece.

The combination of the tool spindle and lower turret in the machine allows the JX 200 to optimise machining methods like simultaneous machining with L/R spindle, upper/lower tools and machining with a centre support mounted on the lower turret.

Aside from the massive potential to enhance your manufacturing process, the JX-200 also sports a stylish appearance with an LED light strip and modern body design.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.