KraussMaffei boosts Mexico’s agricultural industry with sustainable logistics solutions in packaging

Discover how KraussMaffei helped transform eco-friendly packaging in Mexico’s logistics sector—read the full case study now.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

For the greater part of 50 years, electrical discharge machining (EDM) has been changing the way manufacturers change innovation and production into their workday.

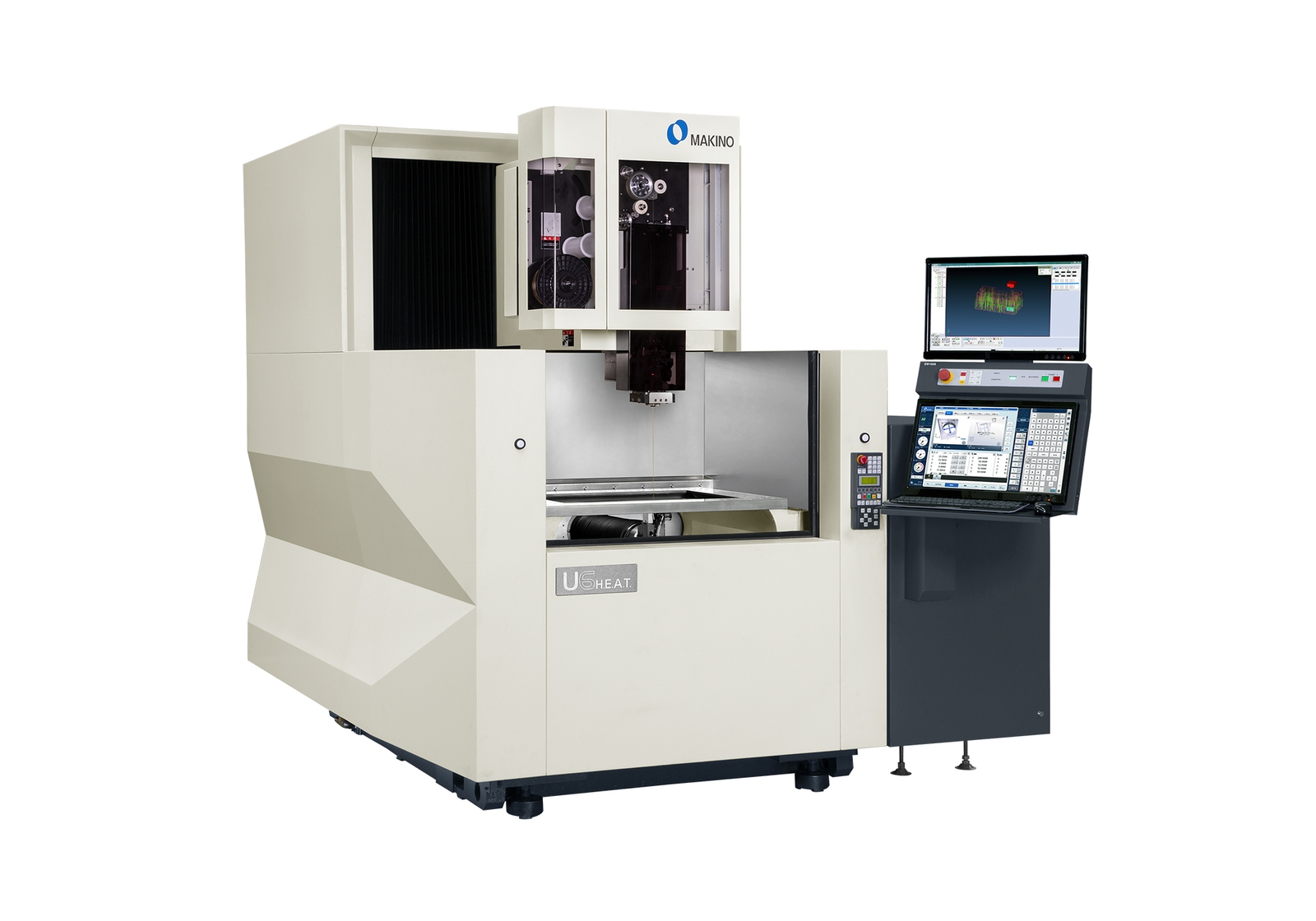

The accuracy and affordability generated by Makino’s range of wire EDM in material removal gives a more precise production and tooling experience than ever before.

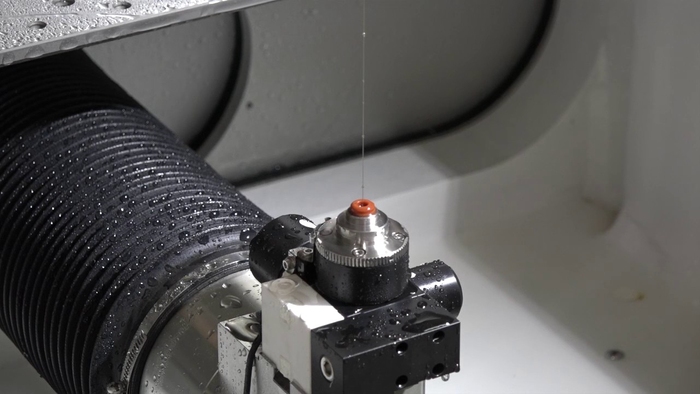

Wire EDM machining (Electrical Discharge Machining) is an electro thermal production process where a thin single strand metal wire, along with de-ionised water (used to conduct electricity) allows the wire to cut through metal by the use of heat from electrical sparks, while preventing rust.

Wire EDM machining works by creating an electrical discharge between the wire or the electrode and the work piece. As the spark jumps across the gap, material is then removed from the work piece and the electrode. Due to the inherent properties of the process, wire EDM can easily machine complex parts and precision components out of hard conductive materials.

To stop the sparking process from shorting out, a non-conductive fluid or dielectric is also used in the process. The waste material is removed by the dielectric, and the process continues.

Whether you require threading small holes in close proximity or general wire EDM work around the shop floor, the Makino range of wire EDM machines are in a class of their own when it comes to material removal.

If you’re interested in discussing our range of Makino Wire EDM machines Enquire Now.

Makino is a world leader in CNC machining centres, high-precision metal cutting technology and EDM machinery, including horizontal machining centres, vertical machining centres, five-axis machining centres, graphite machining centres, and wire and RAM EDM’s.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

EDM machines for sale in Australia and New Zealand from Makino. Wire and Sinker EDM machines for faster part processing.

The EDAF3 machine expands upon the excellent capability and performance of the EDAF2 by offering larger X/Y/Z strokes.

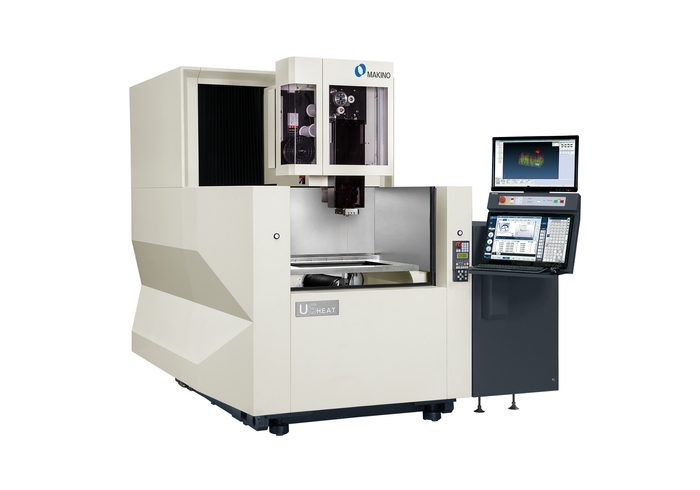

Expands on the diverse capabilities of the U6 with enhancements to the flushing and filtration system