KraussMaffei boosts Mexico’s agricultural industry with sustainable logistics solutions in packaging

Discover how KraussMaffei helped transform eco-friendly packaging in Mexico’s logistics sector—read the full case study now.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

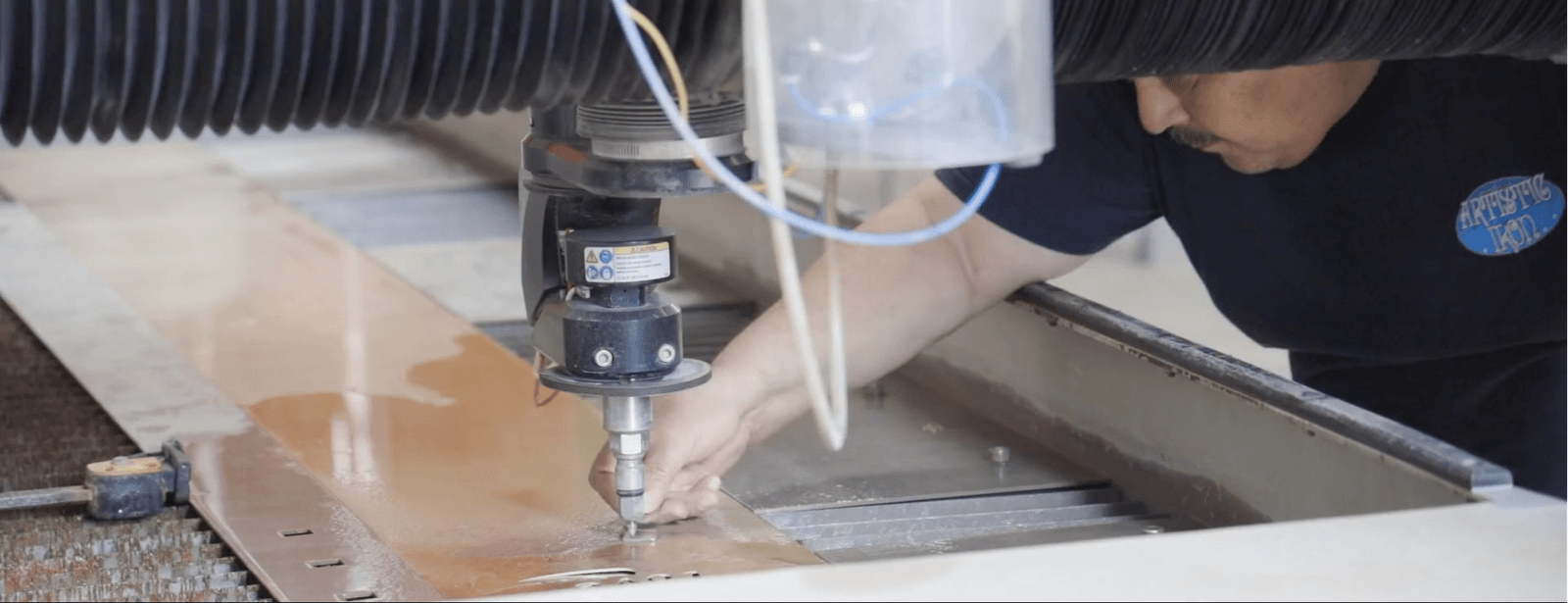

Firstly we explain the process of waterjet cutting is and then dive into the range of materials it can cut including steel and how this is achieved.

Waterjet cutting machines use a high-pressure water stream to erode the material you wish to cut. A granular abrasive is used, usually garnet which is added to the waterjet to increase the cutting power of the machine.

A range of materials can be cut with a waterjet at a high level of of quality and precision.

Waterjet cutting machines can cut a large variety of materials including steel, the different types of steel are detailed below. Furthermore, the variety of other materials are also detailed.

Metal

Waterjet cutting is a cold cutting method, which means there is no heat affected zones, so you’ll achieve a smooth edge with no burn marks, cracking or excess burrs.

Naturals

Within the natural range of materials, you can cut wood, stone and glass. With the low-pressure pierce, vacuum assistance, and water-only cutting you can cut natural materials with confidence.

Glass

Cut ultra-thin panels to thick multi-layered bullet proof panels. Such panels might be used in mobile phones, windows, and vehicles.

Granite

You can cut granite without chipping when compared to a conventional saw.

Leather

Cut with accuracy with a narrow kerf width.

Marble

Cut marble for bathroom and kitchens without the stress of chipping.

Wood

Machine intricate designs or for wood impregnated with additional agents.

Composites

Any fiber reinforced material, including Kevlar can be machined with ease, without any of the conventional draw backs of conventional machining.

Carbon Fiber

The biggest benefit of cutting composites with waterjet technology is there is no need to change the tooling no special considerations or restrictions due to heat build-up, melting or dangerous fumes.

AeroFIBER™

The low pressure pierce, and high control of cutting layered materials. The waterjet can cut AeroFIBER.

FeroForm

FeroForm cuts without fraying on an abrasive waterjet.

Fiberglass

Submerge the material while cutting ensures that the hazardous fumes and dust is eliminated.

G10

Remove the threat of delamination when you cut G10 with a waterjet.

Kevlar

Reduce the risk of hazardous dust or fumes.

Phenolic

Abrasive waterjets leaves a smooth surface on phenolic.

Plastics & Rubber

Reduce any issues of distortion when machining plastic when you cut with cold-cutting techniques associated with a waterjet. The versatility of the waterjet makes it an easy addition to a workshop.

Acrylic

The low-pressure pierce function ensures the waterjet cuts extruded acrylic easily and cleanly.

Foam

When cutting foam, there is no need to use abrasive, just the water-only nozzle is required.

Linoleum Tile

Cut precisely without material distortion.

Plexiglas

Submerging material as you cut, ensures that the likelihood of flying shards is reduced.

Polycarbonate

Reduce the time to cut this material and intricate designs.

Rubber

Use only the water-only nozzle without abrasive to cut this material. Cut soft, fiber-reinforced rubber and very hard rubber cleanly.

If you’re interested in discussing our range of OMAX Waterjet Cutting Machines including the MAXIEM machines discussed above Enquire Now.

OMAX’ high-performance water jet cutting machines are capable of cutting composites, metals, stainless steel, aluminium, titanium, copper, brass, glass, stone, concrete, ceramics, foam and rubber.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.