Changing manual manufacturing: Operator augmentation with InspecVision’s GAV System

Read how InspecVision’s breakthrough system doesn’t replace workers—it gives them X-ray vision and a photographic memory.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

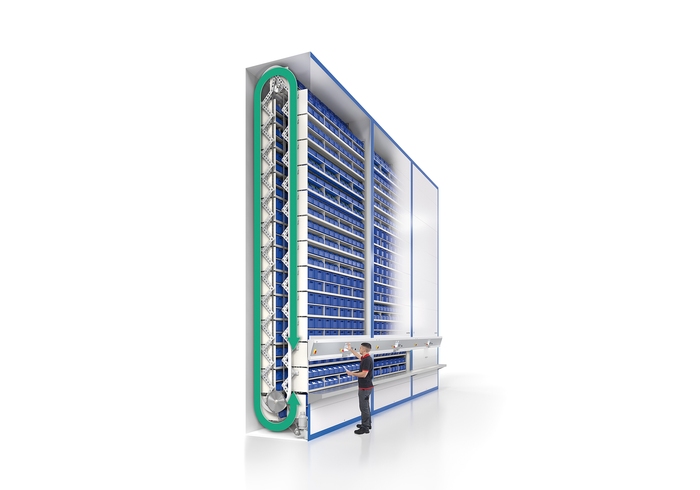

It’s not at all surprising in these times that the Hänel lean lifts have been in demand. Hänel has recently completed a range of medical industry case studies on how the lifts are being used to fast track inventory picking, enabling clients to securely pick high-value items and improve efficiency with Hänel-Soft integrated software.

Topas GmbH has are developers and manufacturers of measurement technology devices and systems. They specialise in particle and aerosol technology. Topas store a range of products in their lean lifts such as, complex equipment for testing filters, filter material and separators.

Topas currently have six Hänel lean-lift systems installed vertically through two production floors. With over nine access points to pick parts and components, the high-speed door enables parallel item picking at any of the access points, speeding up delivery times.

The precise monitoring of who is accessing the lean-lift and what parts they are picking is also monitored through the software.

The efficient linkage of two production floors based on an automated small parts storage solution is a key benefit for Topas, in addition to the flexible software interface, performance and reliability of the Hänel intralogistics solution.

Dr. Andreas Rudolph,

General Manager

Parexel International GmbH is a biopharmaceutical research company that conducts clinical trials for its customers. They support testing of new medications and help accelerate the drug approval processes. Parexel International GmbH currently have two Hänel lean-lift systems installed to help support the fast distribution of publications, medications, laboratory consumables and medical instruments.

For example, when an order calls for an item stored in one of the Hänel lift systems, IPtrack® sends a transport command to the Hänel controller, the container is then automatically brings the item to the access point for picking.

The installation of an automated, digitally-driven storage system significantly expands our capacity and increases our efficiency so that we can accelerate the retrieval, processing and distribution of critical supplies to patients and sites across the EU.

Robert Müller,

Director Production, Labelling & Distribution Services

Clinical Trial Supplies & Logistics

swiss-sonic Ultraschall AG is a supplier of equipment for making medical masks, in addition, they’ve been supporting the medical industry with ultrasonic components for nearly 20 years.

They predominantly looked into incorporating a Hänel lean-lift due to lack of floor space. The company stores printed circuit boards, connectors for ultrasonic welding machines as well as small parts for converters and ultrasonic components used in the automobile, food and medical technology industries. They also produce plastic welding machines used to manufacture premium-grade FFP2 masks.

In addition to reliability and ergonomics, faster picking along with efficient space utilization were also among the decisive factors for choosing the Hänel intralogistics solution.

Casey Bernet,

Managing Director

Read more about swiss-sonic Ultraschall AG

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

The Hanel Lean-Lift is a best-in-class, automated vertical storage carousel that automates the process of storing and retrieving products in warehouses, distribution centers, or manufacturing environments.

The Hänel Rotomat Industrial Storage system is a flexible and adaptable warehouse storage solution that slashes work time and administration costs.

The Hänel Rotomat Office is a vertical filing system that uses available room height in a tight office environment.