KraussMaffei boosts Mexico’s agricultural industry with sustainable logistics solutions in packaging

Discover how KraussMaffei helped transform eco-friendly packaging in Mexico’s logistics sector—read the full case study now.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

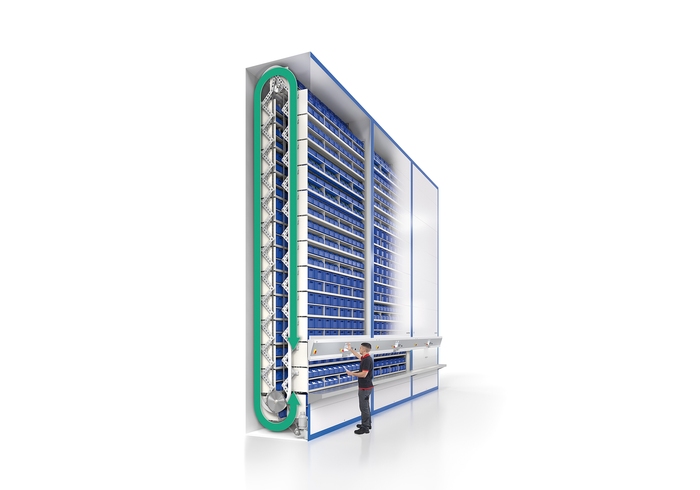

Like many other countries, Australia’s health system is facing storage challenges as the major cities continue to grow and space will become limited. A streamlined storage environment is one of the most critical aspects for many hospitals and healthcare facilities. A streamlined storage environment isn’t just a luxury, it’s an integral part of day-to-day operations. Better storage equals better patient care. On average, nurses dedicate 21 minutes per shift to lost tools and supplies. This can be significantly reduced in a hospital (or any other setting where minutes are a significant factor) through the implementation of quality and advanced technology, such as Hänel’s office and storage system products, including the Rotomat®, Lean-Lift®, and Multi-Space®, which are cutting-edge solutions for automated storage solutions.

This case study demonstrates how AdventHealth Altamonte Springs, Florida USA, utilises Hänel Rotomat® systems to optimise storage space, improve access to surgical instruments and medical supplies, enhance security through access control, and ensure efficient operations in the hospital’s central supply depot. The hospital’s approach exemplifies the integration of advanced technology to streamline processes and enhance patient care. Below you can see how the hospital used to store its medical equipment.

AdventHealth Hospital has 2,300 employees and the very latest medical equipment, including innovative screening technologies, to provide comprehensive medical care in central Florida. The hospital also relies on several Hänel Rotomat® systems. Fast provisioning of operating room material on demand is guaranteed because one Rotomat® storage system is located just a few steps away from the OR area. To ensure that this system would provide maximum storage volume, it was installed in a shaft having a depth of 20 ft/6 m. Since the system has a total height of 26 ft/8 m, an enormous amount of storage capacity is available within a minimum footprint.

The Hänel Rotomat® is used to store surgical instruments in sterile containers to protect them from all kinds of contamination. The retrieval of these containers takes place at the optimum ergonomic height.

The storage system is operated with HänelSoft®-N storage management software. Access control is supported through barcode scanning of employee IDs and contributes to the transparency and security of all storage transactions. Well-organised storage of various medical items in four Hänel Rotomat® systems in the central supply depot. Once logged in, employees enter the item designation using the system terminal to retrieve the article they need. The overview displayed can then be used to select the correct storage position. The sterile containers are transported to the access point quickly, and items can be retrieved for the OR without any chance of errors.

Four other Rotomat® systems are in operation at the hospital’s central supply depot. These automated systems are used to store various medical products and utensils needed to provide nursing care. The storage capacity has been increased considerably because movable shelf racks are no longer needed. All of the lift systems are controlled via HänelSoft®-N which makes put-and-pick operations, as well as inventory management, much easier. The storage positions and items on inventory are identified with HänelSoft®-N and then displayed on the lift control terminal.

An advanced automated storage system can greatly enhance the efficiency and organisation of hospital operations. Headland Technology has a dedicated team of Hänel experts who can assist in developing a customised Intralogistic solution for your hospital. If you have any specific questions or if you’d like to know more feel free to ask!

Watch the video below and see how the Hänel system transformed its storage limitation.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

The Hänel Rotomat Industrial Storage system is a flexible and adaptable warehouse storage solution that slashes work time and administration costs.

The Hänel Rotomat Office is a vertical filing system that uses available room height in a tight office environment.

The Hanel Lean-Lift is a best-in-class, automated vertical storage carousel that automates the process of storing and retrieving products in warehouses, distribution centers, or manufacturing environments.

Automated Storage and Retrieval Systems (ASRS) for sale in Australia and New Zealand from Hanel. Efficiently manage inventory, optimize space, and reduce human labor.