Modern businesses across automotive, agricultural, mining, and manufacturing sectors face an increasingly complex challenge: managing expanding inventories within constrained warehouse spaces. Traditional solutions like facility expansion or relocation carry substantial capital costs and operational disruption. Hanel automated storage and retrieval systems (ASRS) offer a transformative alternative that maximises existing space while revolutionising operational efficiency.

The operational impact of space constraints

Space limitations create cascading inefficiencies throughout warehouse operations. When facilities operate at capacity, several critical problems emerge that directly impact profitability and competitiveness.

Workflow disruption and productivity loss

Overcrowded warehouses force constant reorganisation of inventory, creating bottlenecks that slow operations. Workers spend disproportionate time navigating congested aisles and searching for misplaced components rather than completing value-added tasks. Equipment movement becomes increasingly difficult, with forklifts and material handling equipment struggling through restricted pathways.

Escalating labour and operational costs

These inefficiencies translate directly into increased operational expenses. Additional staff or extended shifts become necessary to maintain output levels in disorganised environments. Time lost searching for inventory, relocating stock, and managing workflow interruptions creates significant overhead costs that compound over time.

Safety and quality risks

Cramped environments substantially increase accident risks for personnel and equipment. Product damage rates rise as handling becomes more difficult in confined spaces. Poor organisation leads to inventory loss, picking errors, and delayed order fulfilment, ultimately impacting customer satisfaction and retention.

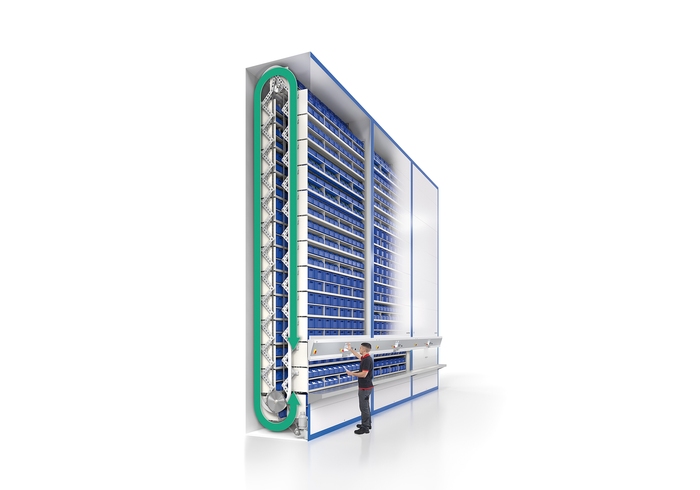

Hanel’s vertical storage solution

Rather than requiring facility expansion, Hänel systems unlock the storage potential of existing vertical space through intelligent automation. These high-density solutions transform warehouse operations by organising inventory in compact, accessible systems that minimise footprint while maximising capacity.

Core system benefits

Maximised vertical capacity: Hänel systems fully utilise available height to dramatically increase storage density for small parts, tools, and components without expanding floor space requirements.

Modular flexibility: Customisable configurations using specialised bins, drawers, and organisational panels accommodate diverse inventory types and workflow requirements across different industries.

Automated precision: Robotic retrieval systems ensure accurate, rapid picking operations while eliminating manual handling errors and reducing physical strain on personnel.

Visual organisation: Integrated management systems with colour-coded storage, clear identification, and visual indicators enable rapid item location and retrieval.

Secure environment: Enclosed storage protects valuable inventory from dust, contamination, and unauthorised access while maintaining precise environmental controls.

Who can benefit from automated storage systems?

While automotive, agricultural, mining, and tooling industries are key sectors for Hanel, the benefits of automated storage units and automated storage retrieval systems (ASRS) extend far wider. Any business that manages parts, tools, stock, or components in a warehouse or distribution centre can gain significant advantages.

Industry-specific applications that benefit most

- E-commerce and retail: Fast order fulfilment and accurate stock control are critical. Automated storage systems reduce picking errors and speed up deliveries.

- Healthcare and pharmaceuticals: Secure, dust-free environments are ideal for storing sensitive medical equipment, medicines, and small consumables.

- Aerospace and defence: Precision is everything, automated storage ensures traceability, compliance, and efficient handling of specialised components.

- Electronics manufacturing: High-density storage protects fragile parts, while automated retrieval reduces the risk of damage.

- Logistics and distribution: Facilities handling thousands of SKUs daily benefit from faster picking and greater space utilisation.

Transformational operational benefits

Hanel Automated Storage and Retrieval Systems (ASRS) implementation delivers measurable improvements across multiple operational metrics:

- Accelerated order fulfillment: Automated picking systems reduce retrieval times and improve accuracy

- Reduced labour costs: Elimination of search time and manual handling inefficiencies

- Enhanced safety: Reduced congestion and forklift traffic in storage areas

- Precise inventory control: Real-time tracking and automated stock management

- Space optimisation: Up to 75% floor space savings through vertical utilisation

Proven market leadership

Hanel’s technology serves diverse industries worldwide, with established partnerships across automotive supply chains, heavy equipment manufacturers, and specialised tooling operations. The company’s German engineering heritage, combined with over 70 years of industry experience, provides reliability and innovation that businesses depend on for critical operations.

Investment perspective

Hanel automated storage systems represent a strategic investment in operational efficiency rather than a simple storage solution. By eliminating the need for facility expansion while improving productivity, these systems typically deliver rapid return on investment through reduced labour costs, improved accuracy, and enhanced operational capacity.

For organisations struggling with space constraints, operational inefficiencies, or rising warehouse costs, Hanel ASRS technology provides a scalable, future-ready solution that transforms existing facilities into highly efficient, organised operations.

Are you looking to optimise space, cut costs, improve safety, and enhance customer satisfaction?

Turn you turn warehouses from manual to intelligent, reactive to proactive. The result? Sustainable growth, happier customers, and a clear competitive edge.

Contact our automated storage experts to explore how Hanel automated storage and retrieval systems can transform your facility’s efficiency and maximise your existing space investment.