KraussMaffei boosts Mexico’s agricultural industry with sustainable logistics solutions in packaging

Discover how KraussMaffei helped transform eco-friendly packaging in Mexico’s logistics sector—read the full case study now.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

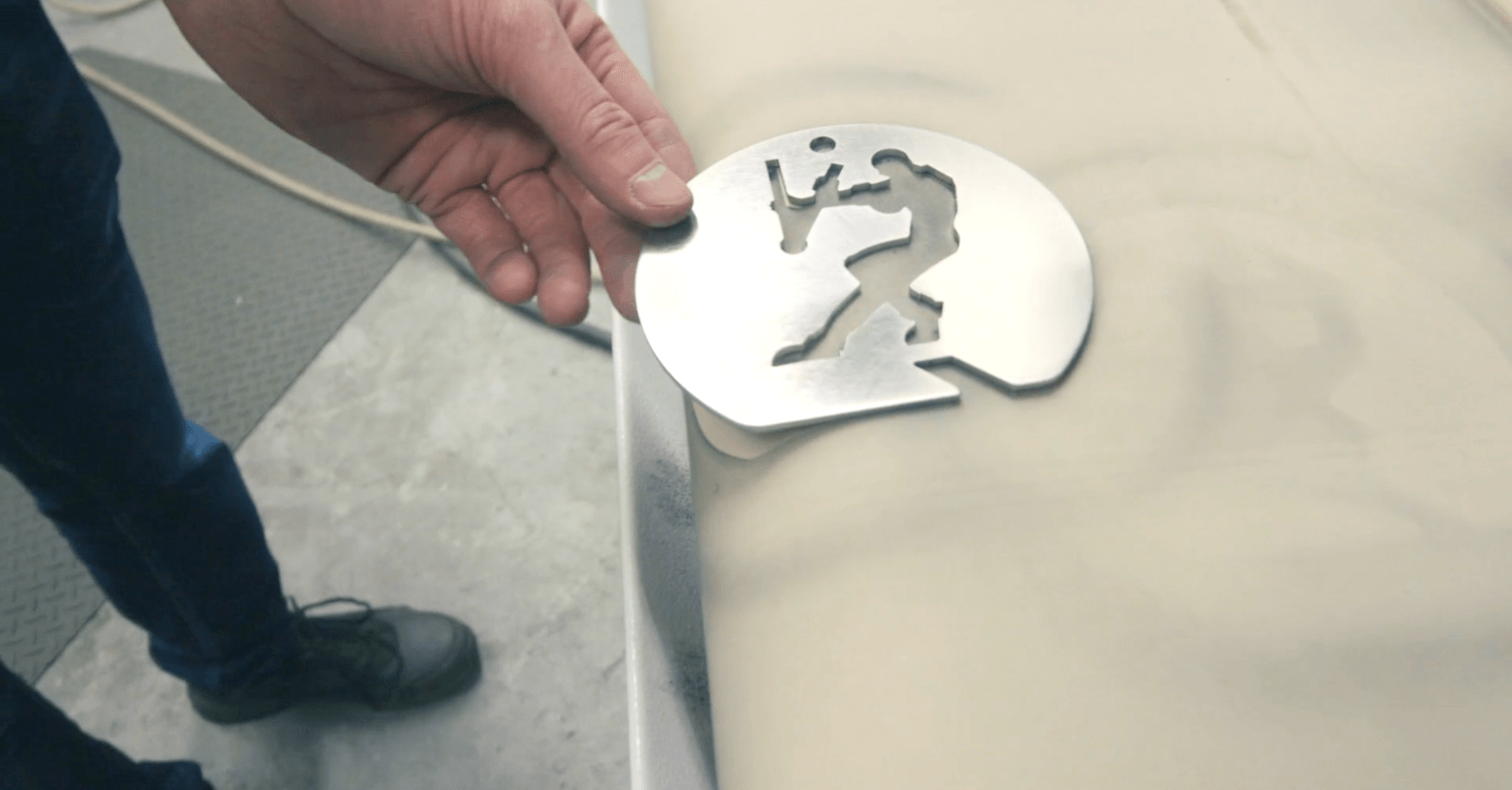

What is deburring? And why are deburring methods important? Of course, accuracy is essential in manufacturing. Reliable machines with specific components can generate accuracy every single time. Let’s define and explore deburring.

High-quality finishes are your goal. So it’s important to remove burrs and generate smooth edges. Parts without burrs or pointy edges means safer handling. It also improves staff safety. No to mention, the look of your items is so much better after deburring.

The latest deburring machinery smooth out surfaces and edges. 30 years ago, metal shops utilised single-belt machines to scratch surfaces. They removed vertical burrs, and generated grain or brush finishes. Yet horizontal burrs or pointy, 90-degree edges occurred.

The latest deburring methods remove burrs from part surfaces, interior, and exterior edges. They assist in producing safer parts that look amazing, ready for processing downstream.

Deburring machines assist with streamlining your manufacturing procedures. This means deburring is an efficient and cost-effective exercise. They assist with standardising all sizes, shapes and perfection levels of your parts. Manual deburring produces different results every time. A machine ensures every part is identical.

Displaced metal is unsafe in certain situations. If sharp edges occur after your cutting process, a deburring method will be necessary. After cutting, a deburring machine assists with smoothing out jagged edges of material. This ensures the safety of your workers and consumers. Accidents can happen. Metals have pointy edging so deburring removes these so staff are not hurt.

Deburring machines also assists with the maintenance and safety of other machinery. Deburr materials before starting the next stage in your manufacturing process. Or sharp edges can get stuck on different parts of other machines.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.