KraussMaffei boosts Mexico’s agricultural industry with sustainable logistics solutions in packaging

Discover how KraussMaffei helped transform eco-friendly packaging in Mexico’s logistics sector—read the full case study now.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

The Australian Chamber of Commerce and Industry (ACCI) recently released a report outlining a significant conundrum facing the manufacturing sector.

On the one hand Australian manufacturing is entering a strong period of growth, on the other that growth is being undermined by labour and supply chain constraints not seen in decades.

Chief Economist at ACCI, Dr Ross Lambie said in the report:

‘Manufacturers (are} continuing to expand their workforce, and expectations for future employment remain positive.

‘However, employers are having increasing difficulties finding experienced workers as a result of domestic and international border closures – these labour constraints are at levels not seen since September 2007.

‘Supply chain disruptions were similarly identified as a major impediment to growth in Australia’s manufacturing output, with material constraints on a scale not seen since the 1970’s oil shock.’

Like other sectors, Australian manufacturing is finding it difficult to find staff to fill positions, which is not only impacting their ability to meet their own orders but is having knock-on effects in the broader economy as supply chain shortages create production bottlenecks elsewhere.

And for those thinking this is purely a covid-related affair as national borders have closed and shipping almost ground to a halt, there are broader and longer-term issues at play.

The closure of technical schools – which have historically been the training ground for manufacturing jobs like boiler-makers – and the general preference of younger generations of Australians to move into digital-based occupations – points to longer term issues in securing the type of skilled workers which the traditional manufacturing set-up accommodate.

With labour shortage a short, medium, and long-term problem, some businesses are using technology workarounds.

Gason is a rural manufacturing business in Ararat that trims motors. Established in 1946, it has seen the rise, decline, and rise again of manufacturing. In the last decade, advanced technology – as well as a rise in relative wages and shipping costs – has changed the face of manufacturing and seen a return of manufacturing to Australian shores.

With demand booming, it has been a period of growth for Gason, but with a lack of available labour to fill the positions and meet demand, Gason has had to look to new technology to meet orders.

Headland Technology recently installed a tool bending machine, the TruBend Cell at Gason, which performs three machines functions by itself: cutting, bending, then placing in storage.

‘Historically, there has been roughly one worker to a machine, helping feed it materials, and someone else helping tool machines in a factory,’ says Headland CEO, George Yammouni.

‘Today, we have machines that can not only feed themselves material, they can fulfil multiple functions that might have been performed by several machines and operators, they can perform quality control, self-diagnosis and order parts or materials.’

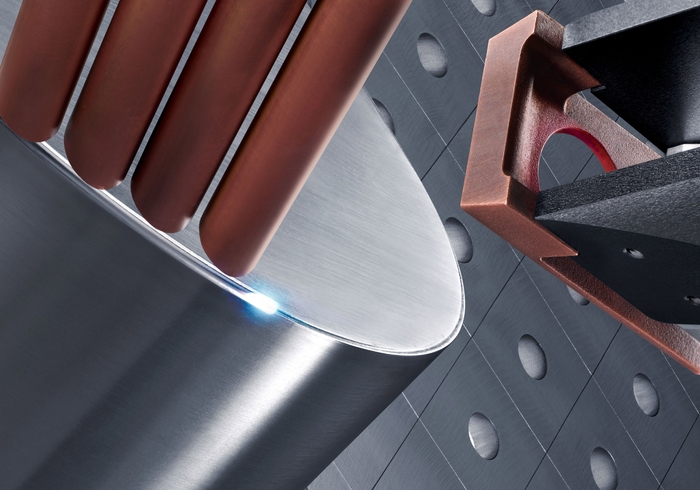

Opie Manufacturing in Emu Plains is another manufacturing business that has found it hard to find welders to meet production quotas. Like Wayne Gason, CEO Tristan Opie consulted Headland Technology to provide them with a technology solution: a TruLaser Weld that can not only produce the output of at least three welders, it doesn’t require another worker to clean the welds and surface either.

George Yammouni points out that long-term trends – from the closure of tech schools to a much more digitally aware and focused younger generations – are compounding with more immediate issues like COVID and supply chain issues to create a productivity crisis in Australia that only technology can fix quickly.

‘Manufacturing jobs today are much more likely to be in software engineering and diagnostics, rather than tool-making, welding, and boiler making.

‘There is a growing and concerning gap between demand and the available labour pool which a technology fund is going to be critical to bridging,’ says Mr Yammouni.

‘Those technology tweaks needn’t mean machines, it could be integrating existing machines and utilising software to get the existing technology to find efficiencies and overcome production road-blocks.’

George Yammouni points out that long-term trends – from the closure of tech schools to a much more digitally aware and focused younger generations – are compounding with more immediate issues like COVID and supply chain issues to create a productivity crisis in Australia that only technology can fix quickly.

‘Manufacturing jobs today are much more likely to be in software engineering and diagnostics, rather than tool-making, welding, and boiler making.

‘There is a growing and concerning gap between demand and the available labour pool which a technology fund is going to be critical to bridging,’ says Mr Yammouni.

‘Those technology tweaks needn’t mean machines, it could be integrating existing machines and utilising software to get the existing technology to find efficiencies and overcome production road-blocks.’

Another piece of technology that is transforming manufacturing processes is the STOPA automated storage system. Connected to process equipment it controls work order, material flows, and facilitates production without supervision. Overnight, it will feed itself, then process, raw material. The system dispatches semi-finished and finished goods before the morning shift starts.

With less workers likely to be available year-on-year, and the cost of acquiring them going up, a technology solution which integrates your current workforce and high-productivity technology and machinery is an important conversation to have.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

Press Brake machines for sale in Australia and New Zealand from TRUMPF. Machines for die and panel bending as well as large format bending.

TRUMPF robot welding machines for sale in Australia and New Zealand. Automated, precision laser and arc metal welding machines.

Automated Warehouse Storage for sale in Australia and New Zealand. Hanel and STOPA storage systems.