KraussMaffei boosts Mexico’s agricultural industry with sustainable logistics solutions in packaging

Discover how KraussMaffei helped transform eco-friendly packaging in Mexico’s logistics sector—read the full case study now.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

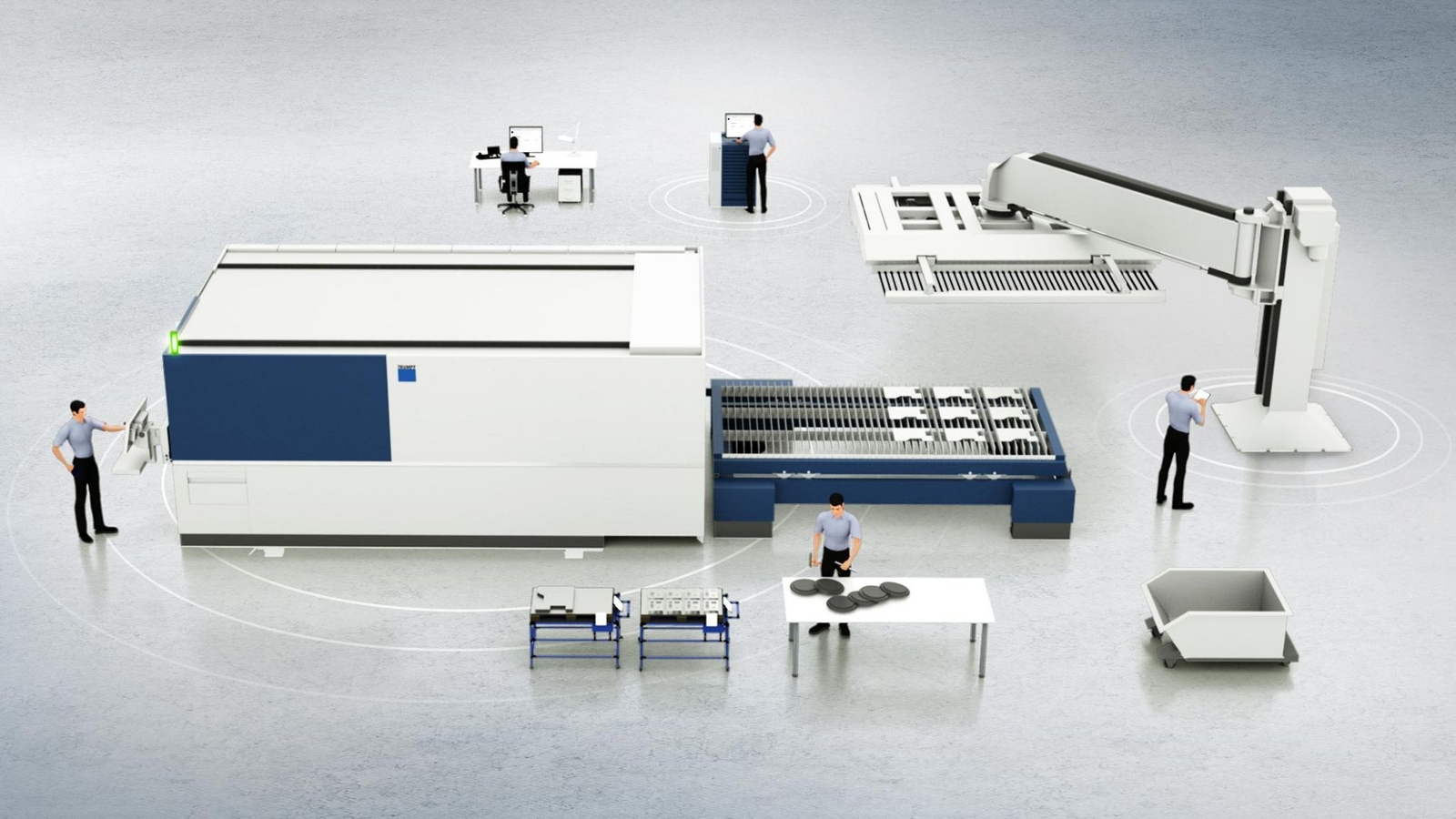

With the interplay of intelligence assistance systems, adaptive machine functions and TRUMPF’s forward thinking ideas, autonomous machines are available now.

Autonomous machines monitor and regulate the machining process, enabling a smooth production process. The operator is in control the entire time with their time dedicated to managing the process, helping to achieve optimal results.

Machines that operate autonomously are the future. With the TruLaser Center 7030 full service laser machine for example, the future is here. This machine hosts a new active speed control system for adaptive feed control. It has the ability to recognise, prevent and resolve malfunctions without human intervention.

Autonomous and partially autonomous technologies can offer easier production management for your 2D laser processing operation.

The key benefits of autonomous production for your factory;

While autonomous machining is the future, machine functions which control processes independently is continually increasing.

Read more about 2D laser cutting and what’s already possible and join the autonomous future.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.