Automation with the TRUMPF TruLaser Cell 1000

Having to deal with rusty, clumsy, or uncoordinated material handling in manufacturing activities can be annoying. The TRUMPF TruLaser Cell 1000 laser machines are one important tool that can provide stability using automation of systems. Having a tool that can minimise or take away burdensome process or manual input would go a long way in achieving increased productivity in fewer time.

Gladly, laser machines with newer technology provide significant differences in processing time. With an automated system, your laser machine brings to bear an uninterrupted process. Most of these automation machines come with modular features that can enable you to modify configurations to suit needs including the number of machines within the cell. They can also help you solve human error problem as their operation output comes with high precision and accuracy. However, these automated laser machines come in different models that offer high beams on time.

In this article, you will learn about the TRUMPF TruLaser Cell 1000 laser welding machine, its features, and application solutions that can enhance efficiency and boost productivity.

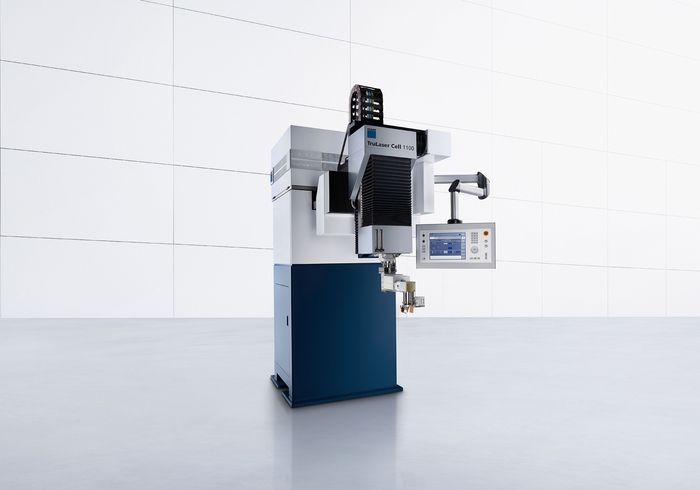

TRUMPF TruLaser Cell 1000

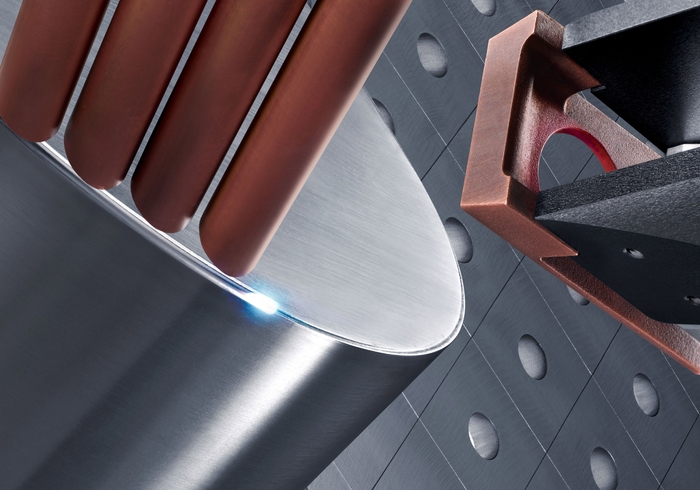

The TruLaser Cell Series 1000 is a cost-effective laser tube welding with a solid-state laser. The machine has a flexible structure and an integrated operating panel that ensures simple control and intuitive operation. It has superior and flexible beam guidance system that is designed for endless welding. The machine also comes with a wide range of welding optics accompanied with linear or swivel axes, as well as sensor systems for seam detection and tracking.

The beam sources and sensor systems reduce operating costs, increase speed and ultimately increase productivity. The flexible beam guidance system can weld any seam geometry on strips, tubes, and profiles, as well as rotationally symmetrical parts. With this laser, you can weld steel, stainless steel, aluminium, and even non-ferrous metals from a tenth of a millimetre up to several millimetres thick.

The laser cell machine allows for endless welding of tubes and profiles. It permits integration into already existing profiling machine without any hassle. With minimal idle time, tubes or profiles can be converted to various product geometries, leak-proof with non-porous weld seam. This is enabled by the high beam quality that brings about highly concentrated energy input to the workpiece. The output is perfect without melt deposits on the inside and outside of the tube walls. The highly productive heat conduction welding also accelerates processes for impressive output. The solid structure of the encapsulated beam guidance system ensures maximum laser safety.

Summarily, the TRUMPF 1000 TruLaser Cell machines bring to the table speed, consistency, and capacity. If a shop has the TRUMPF TruLaser Cell 1000 machine, it is likely to increase its productivity and production capacity to an expanded size in no time at all.