KraussMaffei boosts Mexico’s agricultural industry with sustainable logistics solutions in packaging

Discover how KraussMaffei helped transform eco-friendly packaging in Mexico’s logistics sector—read the full case study now.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

Headland is proud to announce its new partnership with NETSTAL, alongside the introduction of our brand-new plastic machinery division. Swiss company NETSTAL is world renowned for their leading high-performance injection molding machines and systems solutions.

Injection molding is a large industry in Australia where Headland supports new and existing clients with our services and values to help their businesses prosper.

Richard Kloé, Headland Technology’s Managing Director:

“We are very glad to have a highly experienced service team for injection moulding machines on board with more than 50 years of experience.”

The new NETSTAL injection molding machine range is complemented by our dedicated injection molding service team, which is on-site and ready to provide a comprehensive range of services. These services include installation support, breakdown assistance, spare parts, preventative maintenance, software applications, and more. We are committed to helping you maximize the efficiency of your injection molding machines and processes.

NETSTAL machines operate for 25 years and more and are valued across the industry as the most reliable corner piece of their production. Richard Kloé:

“NETSTAL and Headland are a perfect match. They represent our values as NETSTAL machines provide the highest quality, precision, and longevity on the market.“

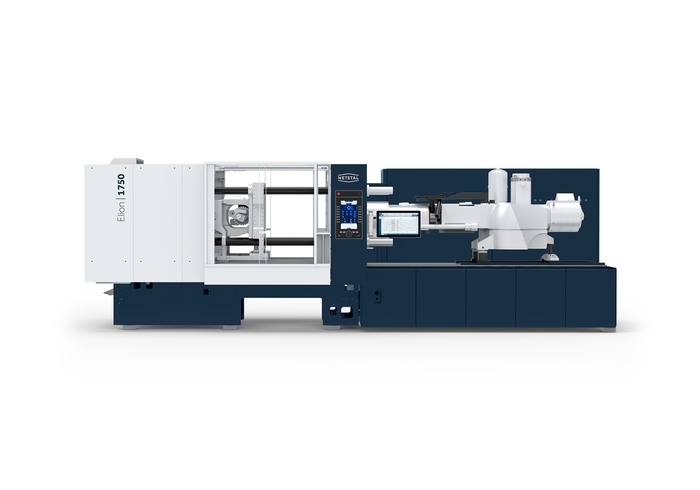

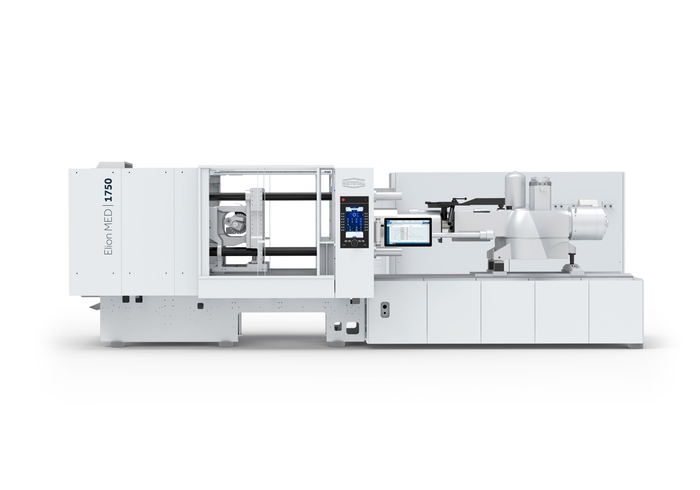

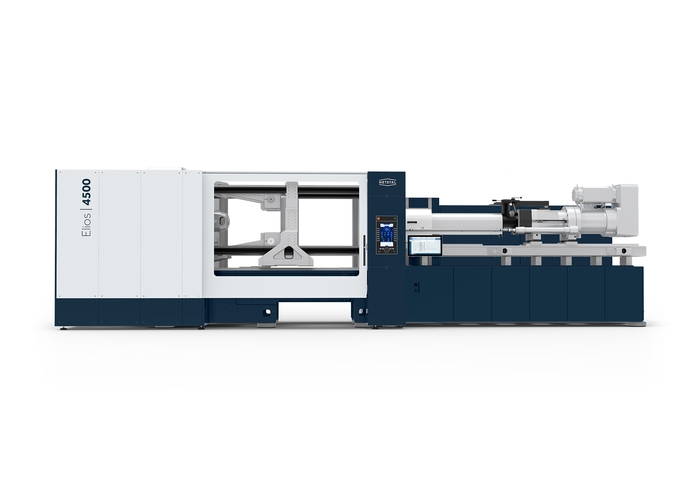

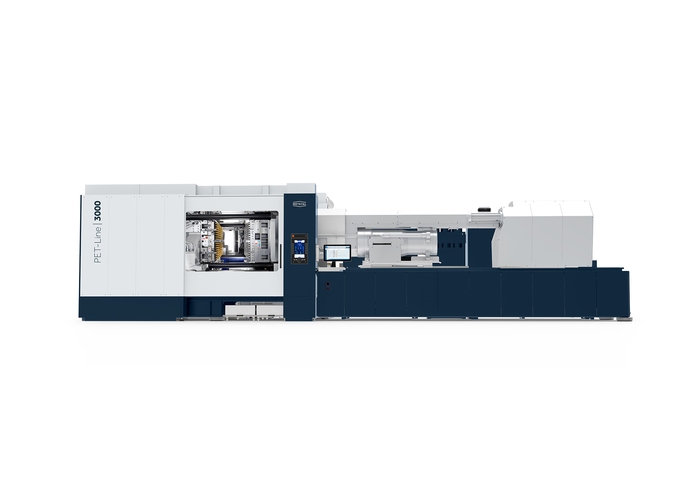

NETSTAL is a Swiss company that is internationally known for its leading high-performance injection molding machines and system solutions. Their product portfolio includes ELIOS and ELION injection molding machines with clamping forces between 800 and 10,000 kN, PET-LINE preform systems for up to 144 cavities, and application-specific turnkey system solutions. Their strategic application areas are in the packaging and beverage industry, as well as in medical technology.

NETSTAL is a global brand with a long and rich history and has regional offices and independent representatives all around the world. The headquarters and only production plant have been located in the neighbouring town of Näfels since 1961. It has been part of the KraussMaffei Group since 1992. NETSTAL is committed to providing its customers with the highest level of efficiency and is actively driving development in the areas of digitalization and circular economy.

NETSTAL and Headland are a perfect match. NETSTAL machines are renowned for their superior performance, quality, and longevity. This makes them the perfect choice for our customers, who value reliable and long-lasting machinery. NETSTAL’s innovative technology and reliable products support sustainability and energy efficiency, which makes them the perfect partner for Headland.

Our injection molding technology experts can help you find the best machine for your business unique needs. Contact us today and learn more about our injection molding machine range.

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

The most crucial features of the Elion series are its speed, accuracy, dependability, user-friendliness, and operational efficiency. “Low energy, high performance” is our motto.

The Elion MED injection moulding machines are the most widely used core element of complex production lines for pipettes, petri dishes, insulin pens, and all other plastic parts in medical technology.

Strong, quick, accurate, energy-saving, and user-focused: The Elios Series creates new standards for high-performance injection moulding with its cutting-edge drive technology.

With full compatibility with existing side-entry moulds and after-cooling stations, the first Netstal PET system with lateral removal is available.