KraussMaffei boosts Mexico’s agricultural industry with sustainable logistics solutions in packaging

Discover how KraussMaffei helped transform eco-friendly packaging in Mexico’s logistics sector—read the full case study now.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

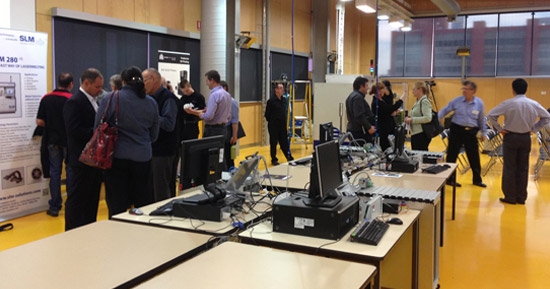

RMIT recently held a seminar at their Advanced Manufacturing Precinct, welcoming over 100 industry visitors to witness their offerings in additive manufacturing, touted to be the next Industrial Revolution.

A leader in Additive Manufacturing, RMIT’s Professor Milan Brandt presented on the University’s latest acquisition, a TRUMPF TruLaser Cell 7020, housed in the Precinct.

“The TruLaser Cell 7020 we acquired from TRUMPF and Headland can be configured for laser cutting, laser welding and laser additive manufacture with both powder and wire feedstock so it is a very versatile machine allowing companies to explore the full potential of laser technology”,

“Given the climate, and with Ford withdrawing their Australian operation by 2016, now is a key time to invest in various new ways of manufacturing, and welding in particular to ensure more efficiencies are gained and processes are automated as much as possible. RMIT are investing heavily in exploring different ways of manufacturing in Australia, within both polymer and the laser metal deposition field.” Professor Brandt says.

RMIT Invest in Proven Technology

RMIT’s decision to invest in the TRUMPF TruLaser Cell was based on their extensive research into TRUMPF’s proven technology and the provision of a complete turnkey solution, including software package, laser and computer numerical control.

Being a world leading educational institution, it was RMIT’s objective to acquire a system that was versatile from the teaching and research perspectives, reliable and can produce consistent results, and TRUMPF’s 3-in-1 laser system achieves exactly this.

Additionally, there are many other different applications for Laser Metal Deposition that require further RMIT research, including but limited to industries such as aerospace, offshore drilling and automotive to name a few.

RMIT will be hosting an Open house for the TRUMPF Laser Cell early next year to demonstrate the capability of the machine.

For more information call 1300 592 061 or email marketing@headland.com.au

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.