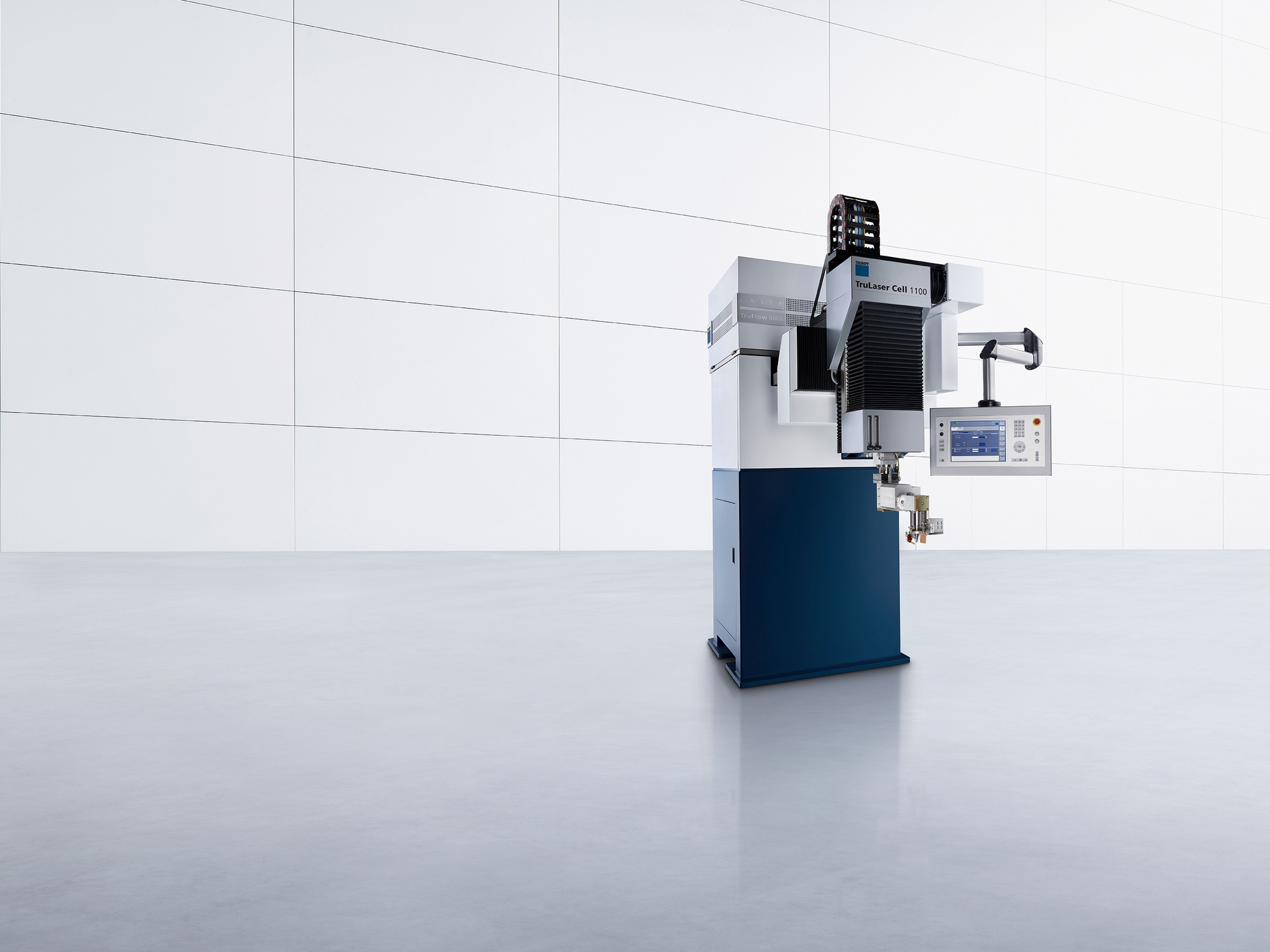

The TruLaser Cell 1100 is a flexible beam guidance system that you can integrate easily into your production line. It is specially designed for the endless welding of any seam geometry on strips, tubes, and profiles.

You have a lot of freedom when it comes to the material. With the laser welding system you can weld steel, stainless steel, aluminum, and even non-ferrous metals, from a tenth of a millimeter up to several millimeters thick.

The flexibility, quality, and reliability are increased through the wide range of welding optics with linear or swivel axes, as well as sensor systems for seam detection and tracking (e.g. SeamLine or SeamLine Pro). Depending on the application and material, either CO2 or solid-state lasers from TRUMPF are used.