Automation with Makino Machining Complex

The complexity of the production process in the factories can be overwhelming. The Makino Machining Complex (MMC) offers an ideal automation solution for manufacturing industries involved in complex processing of cell formation, clamping, assembling, articulation, adjustments, and detailing. This is because industrial production processes require thoroughness, standardisation, precision, and high accuracy if an error will be minimised, time maximised, efficiency improved, and productivity enhanced.

In this article, you will learn the automation options of Makino’s Versatile Intelligent Production (VIP) as well as its features and application solutions that can aid speed, accuracy, efficiency, and productivity.

Makino’s VIP

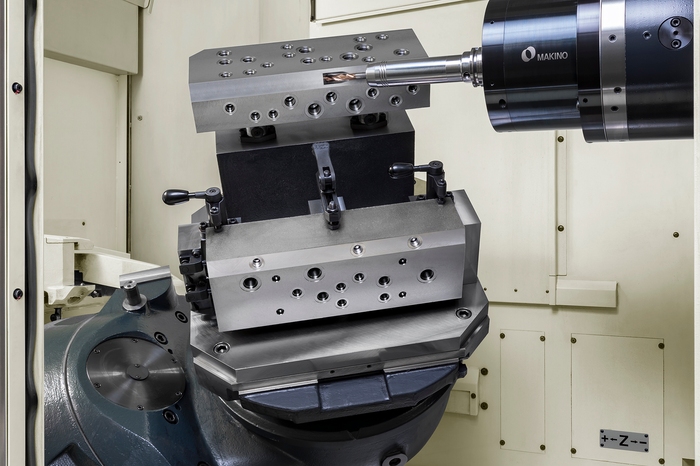

This is a system of automated work-holding pallets that offers standardised zero-clamping system connecting machines and material handling system. This system simulates an automatic pallet interchange that holds materials to be machined. The system permits multiple jobs to be programmed and run automatically on different materials for 24/7 machining. The pallet changer goes in and out and grabs the pallet and takes it to the machine. It also prepares the work set up station and makes it ready for the next job. Here are some application solutions of the Makino’s VIP:

Guaranteed Precision Clamping

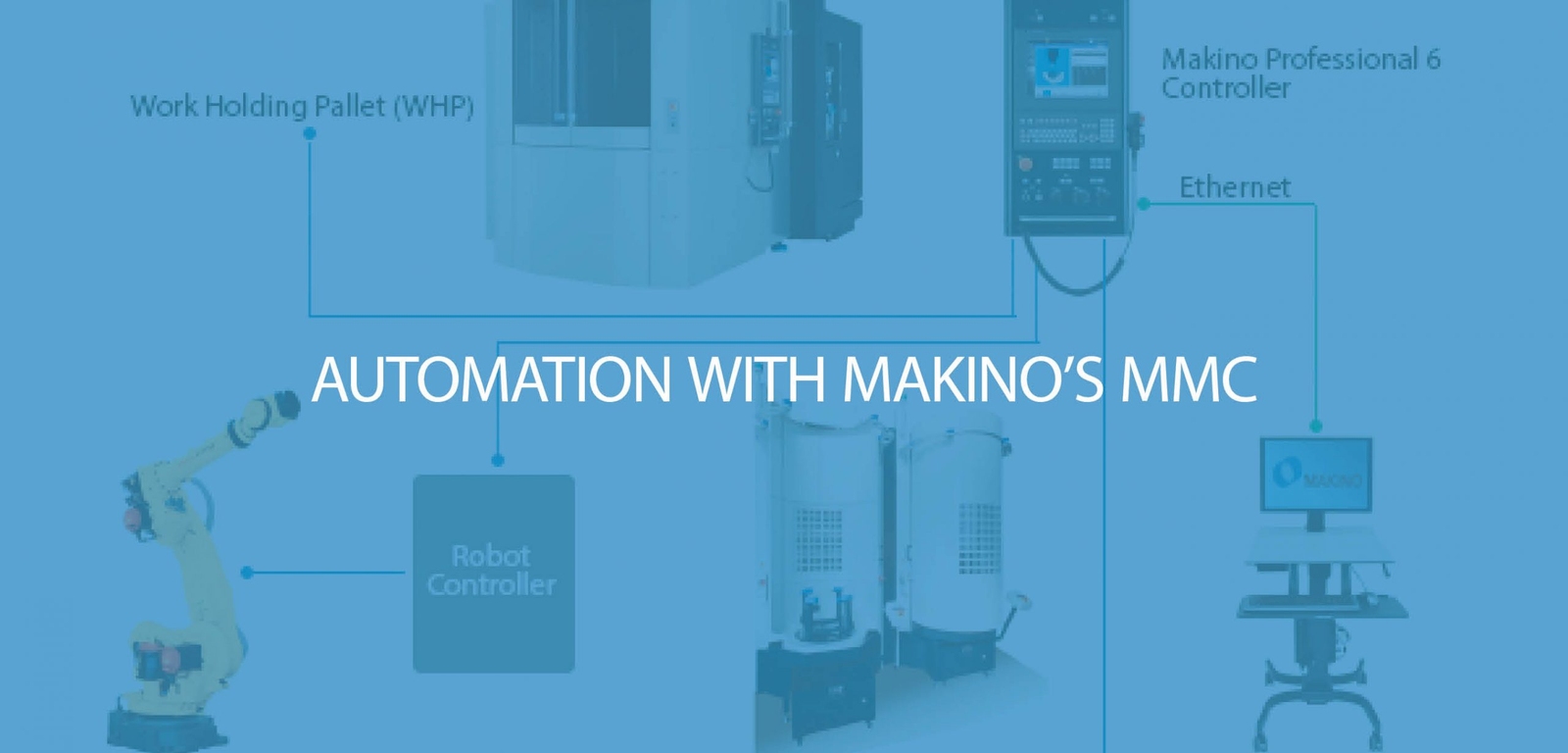

The system component has a 6-Axis Robot for operations and a robot hand (EOAT) for picking and sorting. It also has Work Handling Pallets (WHP) Pots for storage and Stocker for material arrangement. The System Fence with Maintenance Floor shields material from falling off the rail while the System Base ensures a firm grip on the rail during movement. The Work Setting Station provides an interface for the input of intelligent and intuitive commands. The workpiece movement is done using the WHP with the 6-axis robot to ensure zero-clamping system in preparation for both horizontal and vertical machining centers.

Single Machine Solution

With the VIP, a stand-alone machine can be converted into a fully independent machining center that is aided by the Makino Professional 6 controller with a cell control function. This stand-alone version of the VIP offers work management pallet, tool data management, and tool life prediction. It also offers dynamic scheduling, system utility as well as monitoring and report.

Multiple Machine Solution

With the Makino’s VIP, up to 8 Makino machining centers and 4 work setting stations can be connected. What this system offers is seamless and autonomous automation that successfully eliminates human operator input for extremely long hours and overnight operations.

Reach out to experts who can work with you and determine your automation need for your factory capacity in order to scale up efficiency and productivity.

[arve url=”https://youtu.be/96LCafZYWcg” title=”Makino’s MMC, automation for Makino Maching Centers” description=”Makino’s MMC, automation for Makino Maching Centers” loop=”no” muted=”no” /]

Makino’s PZ1

An affordable and quick to install automation system, Makino’s PZ1 is their newest system. This system can grow with your company as you need more modules, simply add and install. This system can be installed from just four days. You can hold multiple pallet sizes within the one system. A safe way to house your pallets. Watch this video to learn more.

[arve url=”https://youtu.be/aLDSeJCsILk” title=”Makino’s PZ1″ description=”Makino’s PZ1″ loop=”no” muted=”no” /]